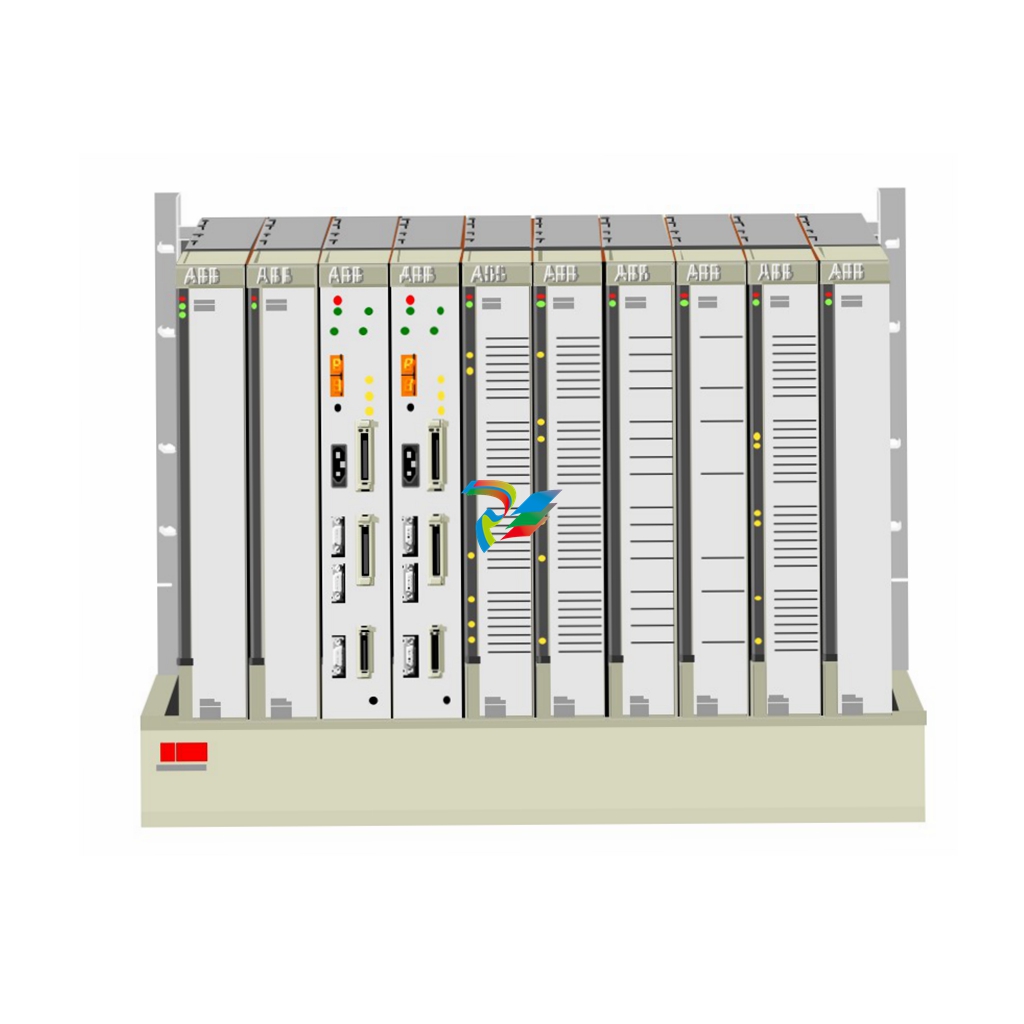

Product Description of Advant Controller 160

Design and Construction

It features a well-engineered design that combines robustness and practicality. The outer casing is typically crafted from high-quality materials such as durable metal alloys or industrial-grade plastics. This sturdy enclosure provides excellent protection against external factors like dust, moisture, mechanical shocks, and temperature variations, ensuring that the internal components are safeguarded and can operate stably in various industrial environments.

Technical Specifications

Processor and Memory: Equipped with a powerful processor that allows for fast and accurate execution of complex control algorithms and tasks. It has a sufficient memory capacity, including both RAM for immediate data handling and flash memory for storing programs, configurations, and historical data. This enables it to manage multiple control loops and handle large amounts of information simultaneously.

Input/Output Capabilities: Offers a diverse range of input and output interfaces. It can support multiple digital and analog input channels, allowing it to connect with various sensors such as temperature sensors, pressure sensors, and position sensors. On the output side, it has a significant number of digital and analog output channels that can drive actuators like motors, valves, and relays to implement precise control actions in industrial processes.

Communication Interfaces: Comes with a variety of communication interfaces, including Ethernet, PROFIBUS, or other industry-standard protocols. These interfaces facilitate seamless integration with other automation devices like programmable logic controllers (PLCs), human-machine interfaces (HMIs), and distributed control systems (DCS). It enables efficient data exchange, remote monitoring, and coordinated control across the entire industrial network.

Programming and Configuration: Compatible with user-friendly programming languages and software tools that make it easy for engineers and technicians to configure the controller according to specific application requirements. They can develop custom control strategies, set up alarm conditions, and monitor the performance of the controller in real-time.

Application Areas

Industrial Automation: Widely used in factory automation, it can manage and optimize production processes in manufacturing plants. For example, it can control the operation of assembly lines, robotic workcells, and material handling systems to improve productivity and product quality.

Process Control: In industries like chemical, pharmaceutical, and food processing, it plays a crucial role in monitoring and adjusting process parameters such as temperature, pressure, flow rate, and chemical concentrations. By maintaining precise control over these parameters, it ensures the stability and safety of the production process.

Power Generation and Distribution: Applied in power plants and power distribution systems, it helps in controlling generators, transformers, and switchgear. It can also manage power flow and monitor electrical parameters to ensure a stable and efficient supply of electricity.

In conclusion, the Advant Controller 31 07KT93 is a sophisticated and dependable controller that combines excellent design, solid technical specifications, and broad application potential, making it an essential

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|