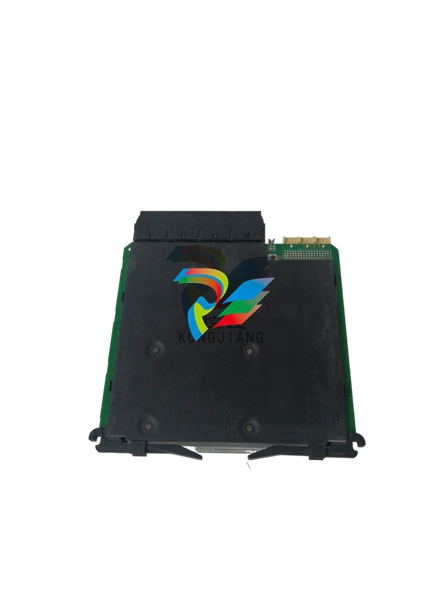

Part Number IS200DACBG1A Manufacturer General Electric Country of Manufacture As Per GE Manufacturing Policy Series Mark VI/VIe Function Module Availability In StockIS200DACBG1A is a Power Supply Board developed by GE. It is a part of EX2100 control system. It provides power to the M1, M2, or C controllers within the EX2100 system. These modules are integral components of the control cabinet setup, ensuring reliable power distribution to the controllers for seamless operation. In the Control Cabinet Components setup, it is capable of supplying power to the designated controllers as required by the system configuration. However, it's essential to note a specific aspect regarding the power source for the DACA modules within the EX2100 system. Features Unlike some other components within the system setup, the power source for the modules doesn't feature a separate switch within the EX2100 system itself. This implies that there isn't a built-in mechanism within the system to directly control the power supply to the modules. Therefore, to manage the power supply to the modules effectively, it's necessary to take manual measures. This involves verifying and ensuring that the external power source connected to the module is switched OFF before performing any maintenance or troubleshooting tasks. This manual verification process typically involves measuring the voltage at the terminal board to confirm that the external power source to the module is indeed in the OFF state. By ensuring that the external power source is deactivated, maintenance personnel can safely carry out tasks without risking electrical hazards or system malfunctions. This precautionary measure helps in maintaining system integrity and safety while handling the power supply components within the EX2100 control system. It underscores the importance of adhering to proper procedures and protocols to mitigate risks and ensure smooth system operation. It features an AC to DC converter that transforms incoming AC voltage into a stable output of 125 volts DC. This output voltage is essential for powering other modules, controllers, and devices within the EX2100 control system, ensuring their proper operation and functionality. The AC to DC conversion process typically involves rectifying the incoming AC voltage to convert it into pulsating DC voltage, followed by filtering and voltage regulation to produce a smooth and stable DC output. This process ensures that the power supplied to the system meets the required voltage levels and remains consistent under different operating conditions. Installation Verify Redundancy and Power: Ensure that the DACA/B module being replaced is redundant, and confirm that the external disconnect switch for the module is in the OFF position. Disconnect Connectors/Cables: Verify that all connectors and cables connected to the DACA/B module are correctly labeled. Disconnect these connectors and cables from the module. Remove Mounting Hardware: Remove the mounting hardware that secures the DACA/B module in place within the cabinet. Remove DACA/B Module: Carefully remove the DACA/B module from its position in the cabinet. Position New DACA/B Module: Orient the new DACA/B module in the same position as the one removed and set it into place within the cabinet. Secure New DACA/B Module: Use the mounting hardware removed in step 3 to secure the new DACA/B module in place. Tighten the mounting hardware according to the specified torque requirements. Verify Power Connection: Ensure that the connector from the DACA/B transformer is correctly plugged into the socket on the DACA/B faceplate that matches the voltage level (115 or 220 V AC) of the control power source. Verify this connection with the external power source to the DACA/B from the EPDM. Note that an input of 220 V AC requires EPDM, Rev B or later. Reconnect Connectors/Cables: Reconnect all connectors and cables that were disconnected in step 2. Tighten the cable connections according to the specified torque requirements. Perform Verification and Testing: Perform any necessary hardware verifications and tests as outlined in the applicable procedure in the EX2100 Installation and Startup Guide to ensure proper functionality of the replaced DACA/B module.AC DC CONVERTER

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|