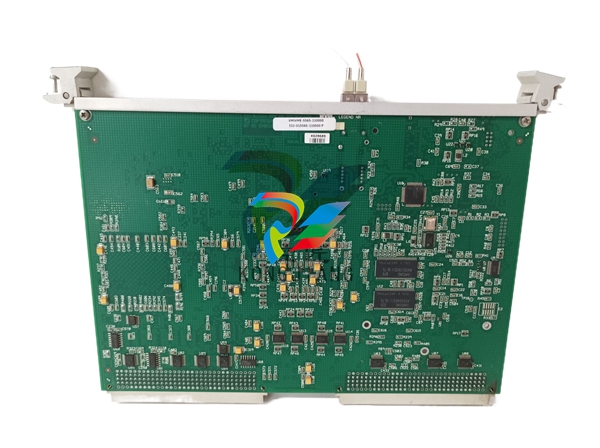

Part Number IS200DVIBH1B Manufacturer General Electric Country of Manufacture As Per GE Manufacturing Policy Series Mark VI/VIe Function Module Availability In StockIS200DVIBH1B is a Vibration Input Terminal Board developed by GE as part of the Mark VI control system. This system includes a central control module linked to an operator interface composed of a PC workstation running a Windows operating system and integrated with turbine hardware. The DVIB board is a compact vibration terminal board that mounts on a DIN rail. It is built to UL 1604 standards for use in a 65 脗掳C Class 1, Division 2 environment. The board features 13 vibration probes: eight vibration inputs, four position inputs, and one keyphasor input. It connects to the VVIB processor board via a 37-pin cable, similar to the larger TVIB terminal board. The VVIB supports up to two DVIB boards. Features Designed for DIN-rail mounting, attaching to a plastic holder that slides along the rail. Compliant with UL 1604 specifications for operation in a 65脗掳C Class 1, Division 2 environment. Available only in simplex configuration. Connects to the VVIB processor board using a 37-pin cable connector. Includes a 42-position screw connection terminal block, with screws 41 and 42 used for SCOM (ground) connections. This link should be as short as possible. Supports eight vibration inputs which can be accelerometer, velocity, proximity, or Velomitor. Each input point is assigned a specific sensor type via jumpers. Includes an onboard chip for diagnostics, performing high/low hardware and software limit checks. Alarms, faults, and trip conditions occur if X or Y probe pairs exceed their limits. Operation The eight vibration inputs on the terminal board can be used for proximitor, accelerometer, seismic (velocity), or Velomitor inputs. Jumpers on the board assign sensor types to each input point: Seismic (S), Velomitor (V), and Proximity/Accelerometer (P/A). The proximitor provides a keyphasor input for phase angle reference once per revolution. All signals are decoupled to ground similarly to the TVIB board. An onboard ID chip identifies the board to the VVIB. Configuration Jumpers JP1A through JP8A select the type of the first eight probes as follows: S: Seismic V: Velocity P: Proximity A: Accelerometer Product Attributes Processes signals from vibration sensors installed on the turbine to provide real-time data to the control system. Compatible with proximity probes for shaft displacement or acceleration and velocity pickups for measuring vibration velocity. Supports both Bently Nevada and other vibration probes. Includes amplifiers and filters for signal processing. Features eight channels, each with its own amplifier and filter circuitry. Includes sensor and output connectors for connecting probes and the control system. Designed for reliability and accuracy in monitoring turbine vibrations, ensuring safe and efficient operation. Characteristics Probe power: -24 V dc from the -28 V dc bus; each probe supply is current-limited to 12 mA per transducer. Rated RPM: Supports eight vibration channels if greater than 4,000 rpm; supports 16 vibration channels and other probes if less than 4,000 rpm. Buffered outputs: Amplitude accuracy is 0.1% for signals to the Bently Nevada 3500 vibration analysis system. Software Maintenance Tools The Mark VI control system is fully programmable, using in-house software automation tools. It integrates proven GE control and protection algorithms with I/O, sequencing, and displays. Contains a software library with general-purpose blocks, math blocks, macros, and application-specific blocks. Operates on a QNX operating system with real-time applications, multitasking, and priority-driven scheduling. Supports software frame rates of 10, 20, and 40 milliseconds, with the ability to make changes to application software during operation. All application software is stored in non-volatile flash memory in the Control Module. Connectivity Establishes a robust connection to the VVIB processor board via a 37-pin cable connector, ensuring reliable communication within the system. Includes a 42-position screw connection terminal block for secure SCOM (ground) connections. Enhanced Diagnostics High/Low Hardware Limit Checks: Monitors parameters against predefined thresholds to detect deviations, such as voltage or temperature measurements. High/Low Software Limit Checks: Employs software-defined limits to compare data against thresholds within the system's software parameters. Responses to Limit Exceedance: Probe Alarms: Alerts are raised for deviations from established limits. Fault Identification: Logs faults related to exceeded limits for diagnosis. Trip Conditions Activation: Triggers emergency protocols or shutdowns in critical situations. Installation and Connectivity Insert the equipment into the dedicated plastic holder for DIN-rail mounting to ensure stability and ease of access. Connect vibration probes to the DVIB board via a 42-terminal block, ensuring a secure link between the probes and the board.TERMINAL BOARD

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|