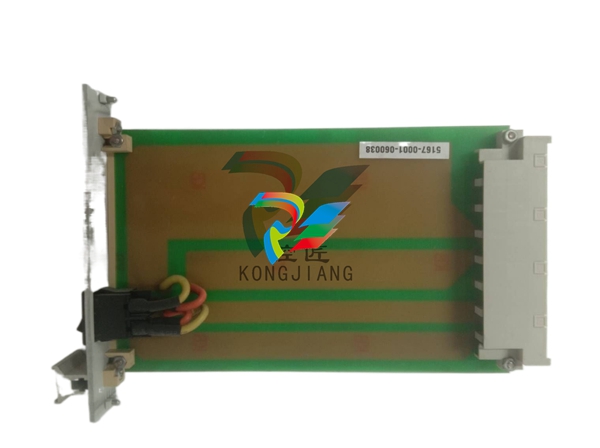

Part Number IS200HFPRG1A Manufacturer General Electric Country of Manufacture As Per GE Manufacturing Policy Series Mark VI/VIe Function Module Availability In StockIS200HFPRG1A is a high-frequency power supply board designed and developed by GE. It is a part of the Drive Control system and is commonly employed in drives belonging to the Type H Medium Voltage Innovation series. The component ensures the proper functioning of these drives. The board operates on a 24 VAC square wave input, which is generated and regulated by a constant voltage control power transformer. This transformer maintains a stable and consistent voltage supply to the board, ensuring reliable performance of the connected drives. To ensure the safety and protection of the board and the overall system, all input and output voltages are equipped with fuse protection. Fuse protection serves as a safeguard against excessive currents or voltage surges, preventing potential damage to the board and other connected components. This feature enhances the overall reliability and durability of the drive control system by mitigating electrical abnormalities or overloads, thereby protecting sensitive electronic components and maintaining operational efficiency. Features Purpose and Design This board is specifically designed to function as a high-frequency power supply for Innovation Series Medium Voltage (GP Type H) drives, ensuring optimal power delivery for their operation. Power Delivery Mechanism Operates using a constant voltage control power transformer, supplying a stable 24 VAC 50/60 Hz square wave input for consistent and reliable power distribution. Safety Measures Equipped with fuse protection for all input and output voltages to ensure the safety and protection of the board's components. Connectivity Consists of six plug connectors: HFPL1 and HFPL2 for power supply connections, FAPL1 and FAPL2 for fan power supplies,

and C1PL and C2PL for external capacitor connections. Visual Status Indicators Features two LEDs that serve as visual indicators to display the power supply output status, providing convenient monitoring of the board's operation. Protection Mechanisms Incorporates five fuses to safeguard components and circuitry against potential faults or electrical issues. Terminal Board and External Connections Includes a terminal board to facilitate secure connections of external wires or cables, ensuring ease of installation and maintenance. Replacement Procedures and Safety Guidelines Detailed replacement instructions are available in manuals or user guides specific to the HFPRG1A associated with this component. Proper de-energizing procedures before maintenance tasks are essential. Guidance can be found in relevant manuals like GEH-6133 for liquid-cooled drives or GEH-6131 for air-cooled (solid-state) drives, ensuring safety and proper handling during drive maintenance. Characteristics The High-frequency Power Supply Board designed for Innovation Series Medium Voltage (GP Type H) drives is equipped with several features that make it highly suitable for its intended purpose. One of its key components is a high-frequency transformer, which efficiently converts and delivers power to the connected drives. The high-frequency nature of the transformer allows for improved power transfer and reduced energy losses. The board incorporates a high-voltage rectifier, which converts incoming alternating current (AC) power into direct current (DC) power. This rectification process ensures that the drives receive a stable and consistent power supply, enabling them to operate effectively. Overcurrent protection safeguards against excessive current flow, preventing damage to the board and connected components. Overvoltage protection prevents voltage spikes or surges from reaching the drives, safeguarding them from potential damage. Thermal protection mechanisms monitor the temperature of the board and its components, activating safety measures if overheating occurs to prevent any potential hazards. The board features multiple inputs and outputs, allowing for seamless integration with other components in the control system. Power input connectors enable the board to receive the necessary power supply, ensuring uninterrupted operation. Ignition output connectors facilitate the ignition process of the drives, enabling them to start up efficiently. Communication connectors provide the means for the board to interact with other control system components, facilitating data exchange and coordination. Efficiency and compactness are essential design considerations for the board. Its compact form factor allows for easier installation and integration within limited spaces. Additionally, the board exhibits a high power density, meaning it can deliver significant power output relative to its size. This high power density contributes to the overall efficiency of the system. Moreover, the board is designed to minimize heat dissipation, ensuring optimal operation and reducing the need for additional cooling mechanisms. Fault Conditions Power supply faults are classified into three types: Temporary Output Disabling Faults: These faults occur when a power supply fault results in the temporary disabling of the output. Triggered by conditions such as overvoltage, overcurrent, or overtemperature, the power supply automatically shuts down or enters a protection mode. Once the fault condition is resolved, the power supply can resume normal operation without manual intervention. Reset-Action Required Faults: These faults occur when a power supply fault is detected but cannot be automatically resolved. A manual reset action is required to clear the fault and restore normal operation. Resetting may involve cycling the power or using a dedicated reset button or switch. These faults indicate more serious issues that require attention and troubleshooting. Permanent Failure Requiring Supply Replacement: This type of fault signifies a permanent failure within the power supply unit that cannot be repaired. It usually results from severe electrical stress, component aging, or manufacturing defects. In such cases, the faulty power supply must be replaced to restore power to the system. Operation Power Supply and Status LED Indicators: The power supply unit typically features a power switch located on the front panel to control the activation and deactivation of the output voltages. It also includes three LED indicators for status feedback: The yellow LED indicates input power status, showing whether the power supply is receiving the correct input power. The red LED serves as a fault indicator, illuminating when a fault condition is detected within the power supply or the connected system. The green LED signifies normal operation, indicating that the power supply is functioning correctly without any active fault conditions. Connectors HFPL1/HFPL2: Power supply connections. FAPL1/FAPL2: Fan power supply connections. C1PL/C2PL: Connect to external capacitors.HIGH FREQUENCY PWR S

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|