Key Features:

1) Advanced Vibration Monitoring: The 125808-06 is equipped with state-of-the-art sensors and signal processing capabilities to provide accurate and real-time vibration data. This allows for early detection of potential issues and proactive maintenance.

2) High Reliability: Built to withstand harsh industrial environments, this model is designed for continuous operation and long-term reliability. It can withstand extreme temperatures, vibrations, and other challenging conditions.

3) Easy Integration: The 125808-06 can be easily integrated into existing monitoring systems and networks, allowing for seamless data transfer and analysis. It is compatible with a wide range of software platforms and communication protocols.

4) Remote Monitoring: With remote monitoring capabilities, users can access real-time data and alerts from anywhere, ensuring timely response to any potential issues. This feature is especially valuable for facilities with multiple locations or remote sites.

Typical Usage Scenarios:

1) Power Industry: The 125808-06 is ideal for monitoring turbines, generators, compressors, and other critical equipment in power plants. It helps prevent unexpected downtime and costly repairs by detecting issues before they escalate.

2) Petrochemical: In petrochemical plants, this model can be used to monitor pumps, motors, and other machinery to ensure safe and efficient operation. It helps identify potential failures early on, reducing the risk of accidents and production losses.

3) General Automation: For general automation applications, the 125808-06 can be used to monitor a wide range of equipment, including conveyor systems, HVAC units, and manufacturing machinery. It provides valuable insights into machine health and performance.

Basic Advantages:

1) Improved Equipment Reliability: By continuously monitoring vibration levels, the 125808-06 helps extend the lifespan of critical equipment and reduce the risk of unexpected failures.

2) Cost Savings: Proactive maintenance based on real-time data can help save on repair costs, downtime, and lost production.

3) Enhanced Safety: Early detection of potential issues can help prevent accidents and ensure a safe working environment for employees.

4) Increased Efficiency: By optimizing maintenance schedules and identifying inefficiencies, this model can help improve overall operational efficiency.

Related Models:

1) Bently Nevada 125800-02

2) Bently Nevada 3500/25-01-01-00

3) Bently Nevada 3500/22-01-01

4) Bently Nevada 3500/45-08

5) Bently Nevada 144403-01

6) Bently Nevada 126615-01

7) Bently Nevada 149716-01

8) Bently Nevada 133450-01

9) Bently Nevada 3500/42-07-01

10) Bently Nevada 162291-01

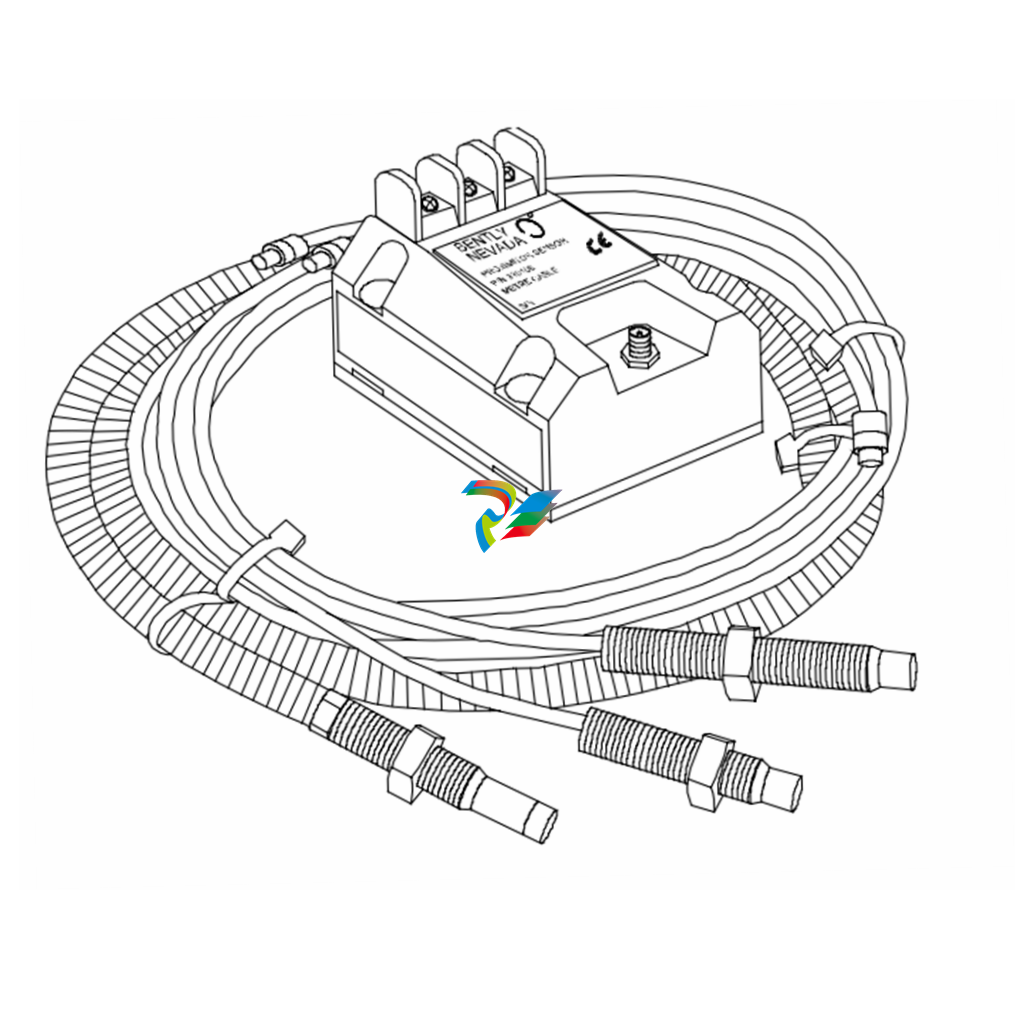

Bently Nevada 125808-06 - Relay Module

Bently Nevada 125808-06 - Relay Module

The Bently Nevada 125808-06 is a top-of-the-line vibration monitoring system designed for use in the power industry, petrochemical, and general automation sectors. With its advanced features and robust construction, this model is a reliable choice for monitoring critical machinery and ensuring optimal performance. Key Features: 1) Advanced Vibration Monitoring: The 125808-06 is equipped with state-of-the-art sensors and signal processing capabilities to provide accurate and real-time vibration data. This allows for early detection of potential issues and proactive maintenance. 2) High Reliability: Built to withstand harsh industrial environments, this model is designed for continuous operation and long-term reliability. It can withstand extreme temperatures, vibrations, and other challenging conditions. 3) Easy Integration: The 125808-06 can be easily integrated into existing monitoring systems and networks, allowing for seamless data transfer and analysis. It is compatible with a wide range of software platforms and communication protocols. 4) Remote Monitoring: With remote monitoring capabilities, users can access real-time data and alerts from anywhere, ensuring timely response to any potential issues. This feature is especially valuable for facilities with multiple locations or remote sites. Typical Usage Scenarios: 1) Power Industry: The 125808-06 is ideal for monitoring turbines, generators, compressors, and other critical equipment in power plants. It helps prevent unexpected downtime and costly repairs by detecting issues before they escalate. 2) Petrochemical: In petrochemical plants, this model can be used to monitor pumps, motors, and other machinery to ensure safe and efficient operation. It helps identify potential failures early on, reducing the risk of accidents and production losses. 3) General Automation: For general automation applications, the 125808-06 can be used to monitor a wide range of equipment, including conveyor systems, HVAC units, and manufacturing machinery. It provides valuable insights into machine health and performance. Basic Advantages: 1) Improved Equipment Reliability: By continuously monitoring vibration levels, the 125808-06 helps extend the lifespan of critical equipment and reduce the risk of unexpected failures. 2) Cost Savings: Proactive maintenance based on real-time data can help save on repair costs, downtime, and lost production. 3) Enhanced Safety: Early detection of potential issues can help prevent accidents and ensure a safe working environment for employees. 4) Increased Efficiency: By optimizing maintenance schedules and identifying inefficiencies, this model can help improve overall operational efficiency. Related Models: 1) Bently Nevada 125800-02 2) Bently Nevada 3500/25-01-01-00 3) Bently Nevada 3500/22-01-01 4) Bently Nevada 3500/45-08 5) Bently Nevada 144403-01 6) Bently Nevada 126615-01 7) Bently Nevada 149716-01 8) Bently Nevada 133450-01 9) Bently Nevada 3500/42-07-01 10) Bently Nevada 162291-01

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|