DCS; Industrial control system

Product

Article

NameDescriptionContent

Argument

Current Location:

PRODUCT SHOW

Description

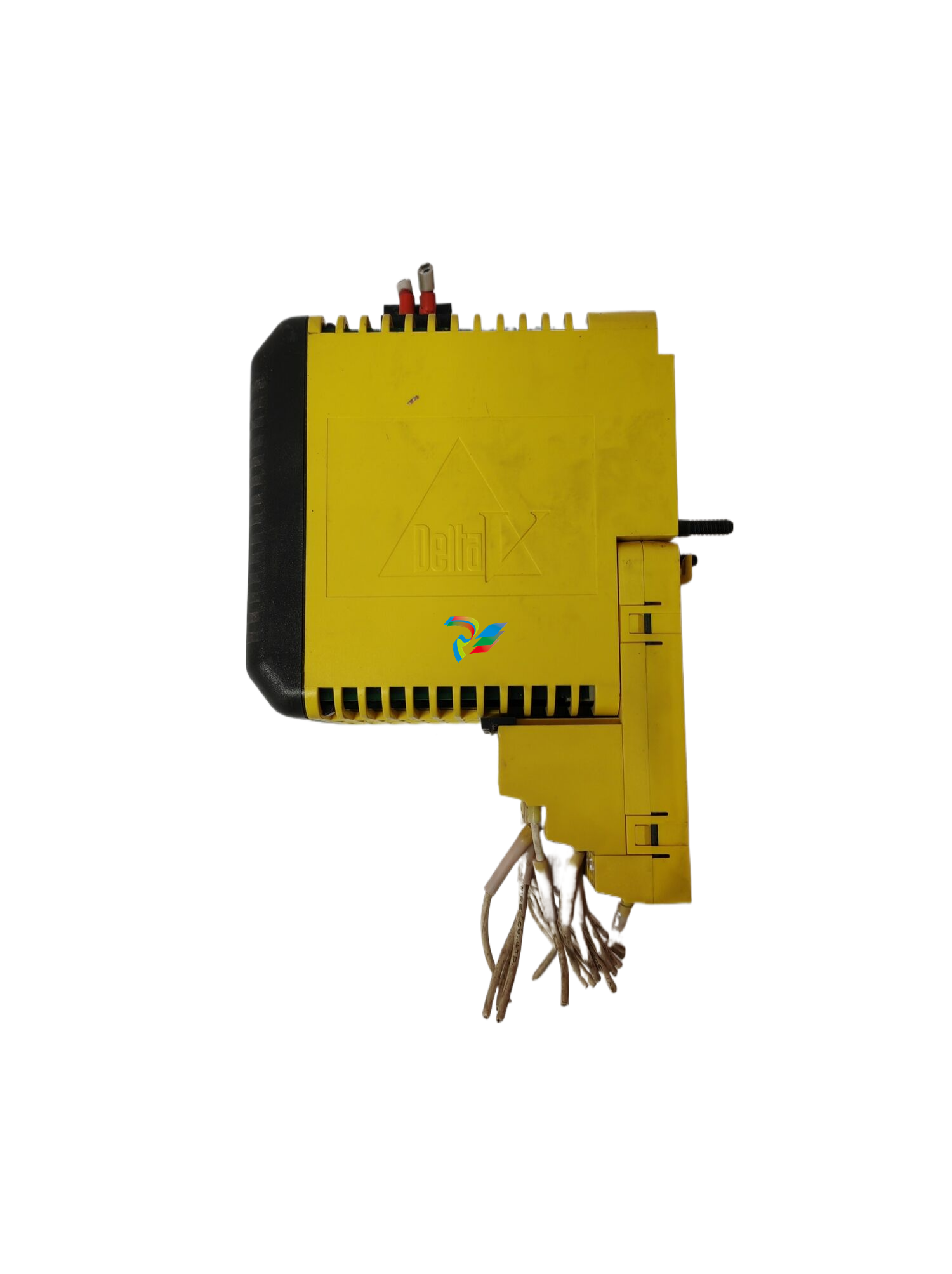

Introducing the Emerson,Smart Process Integration Process Integration, the latest addition to the renowned Emerson Smart Process Integration product line. This cutting-edge device is designed to revolutionize the way industries approach power generation, petrochemical processing, and general automation tasks. With its advanced features and seamless integration capabilities, the Process Integration model sets a new standard for efficiency and performance in industrial automation.

Emerson,Smart Process Integration Process Integration - System Integration

Emerson,Smart Process Integration Process Integration - System Integration

Introducing the Emerson,Smart Process Integration Process Integration, the latest addition to the renowned Emerson Smart Process Integration product line. This cutting-edge device is designed to revolutionize the way industries approach power generation, petrochemical processing, and general automation tasks. With its advanced features and seamless integration capabilities, the Process Integration model sets a new standard for efficiency and performance in industrial automation.

Key Features:

1) Seamless Integration: The Process Integration model seamlessly integrates with existing Emerson Smart Process Integration products, allowing for easy implementation and enhanced functionality.

2) Advanced Monitoring Capabilities: With state-of-the-art monitoring systems, the Process Integration model provides real-time data analysis and diagnostics, ensuring optimal performance at all times.

3) Process Optimization: The Process Integration model offers innovative process optimization tools, allowing for increased efficiency and productivity in power generation and petrochemical applications.

4) Energy Monitoring: With built-in energy monitoring capabilities, the Process Integration model helps industries track and manage energy consumption, leading to cost savings and environmental benefits.

5) Data Analytics: The Process Integration model comes equipped with advanced data analytics tools, enabling industries to make informed decisions based on actionable insights.

6) Safety Systems: The Process Integration model includes safety systems features to ensure compliance with industry regulations and standards, safeguarding both equipment and personnel.

7) Industrial Control: The Process Integration model provides precise industrial control functions, enabling industries to maintain optimal operating conditions and maximize productivity.

8) Real-Time Monitoring: The Process Integration model offers real-time monitoring capabilities, allowing industries to respond quickly to changing conditions and minimize downtime.

Typical Usage Scenarios:

1) Power Industry: The Process Integration model is ideal for power generation applications, offering advanced monitoring and optimization tools to improve operational efficiency and reliability.

2) Petrochemical Processing: In petrochemical processing plants, the Process Integration model helps streamline operations and enhance safety measures through its integrated safety systems and control modules.

3) General Automation: For general automation tasks, the Process Integration model provides a versatile solution with its comprehensive range of features, including energy monitoring and data logging capabilities.

Basic Advantages:

1) Enhanced Efficiency: The Process Integration model streamlines industrial processes, leading to increased efficiency and productivity.

2) Improved Safety: With integrated safety systems, the Process Integration model ensures a safe working environment for personnel and equipment.

3) Cost Savings: By optimizing processes and monitoring energy consumption, the Process Integration model helps industries reduce operational costs and improve sustainability.

Related Models:

1) Emerson,Smart Process Integration Monitoring Systems

2) Emerson,Smart Process Integration Diagnostic Tools

3) Emerson,Smart Process Integration Process Optimization

4) Emerson,Smart Process Integration Energy Monitoring

5) Emerson,Smart Process Integration Data Analytics

6) Emerson,Smart Process Integration Safety Systems

7) Emerson,Smart Process Integration Industrial Control

8) Emerson,Smart Process Integration Real-Time Monitoring

9) Emerson,Smart Process Integration Control Systems

10) Emerson,Smart Process Integration Data Logging

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Customer Reviews

Satisfaction :

5 Stars

No evaluation information