Fisher 4660 5-95PSI High-Low Pressure Pilot

Fisher™ 4660 High-Low Pressure Pilot

The Fisher 4660 pneumatic high-low pressure pilot

activates safety shutdown systems for flowlines,

production vessels, and compressors. This pilot is

available with either single or dual set point capability,

using switch points to maintain full output pressure

when the process pressure is within the set point

range. If the process pressure is outside this range, the

pilot switches from full output pressure to zero output

pressure.

The primary switching mechanism in this pilot is a

block-and-bleed relay assembly. This construction can

be used in both block-and-bleed and bleed-only

systems.

Unless otherwise noted, all NACE references are to

NACE MR0175-2002.

Features

Safety Certification—The 4660 is certified for use in

Safety Instrumented System (SIS) applications.

Certification is by exida Consulting LLC, a global

provider of functional safety and control system

security (see figure 1). SIS certification is identified

on the product by a label affixed to the case.

The functional safety assessment was performed to

the requirements of IEC 61508: ed2. 2010. SIL3 for

mechanical components.

Superior Performance—Repeatability meets the U.S.

Minerals Management Service test tolerances

referenced in Outer Continental Shelf (OCS) Order

No. 5 and defined in the American Petroleum

Institute (API) RP14C standard.

Cost-Effective Design—One pilot provides either a

high-low function or a single switch point,

whichever the application requires

NACE Conformance—A NACE compliant Bourdon

tube is available for those applications where the

pilot must meet the requirements of NACE

MR0175-2002.

Environmental Packaging—Construction materials

have been selected to protect the pilot from

corrosive environments such as the salt spray

atmosphere of offshore platforms.

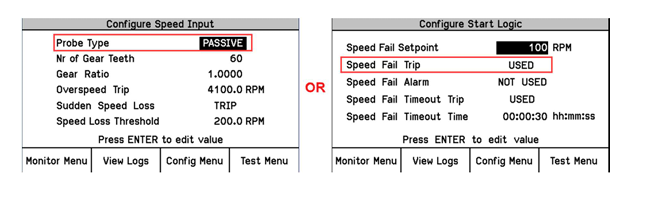

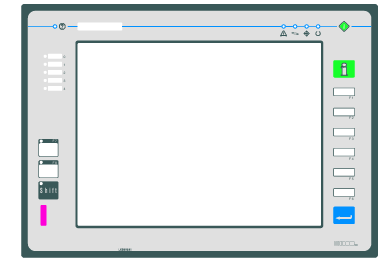

Reliable Operation—The pilot uses a field-proven

Bourdon tube process pressure sensing element,

shown in figure 2. that reduces maintenance by

eliminating the need for wetted dynamic O-rings.

Reduced Air/Gas Consumption—The 4660

pneumatic high-low pressure pilot is an energy

efficient choice. The low bleed relay provides a

steady state consumption rate that is less than the

6 scfh requirement set for the oil and gas industry

by the US Environmental Protection Agency

(New Source Performance Standards Subpart

OOOO, EPA-HQ-QAR-2010-0505).

Vibration Resistance—The rugged Bourdon tube

sensing element and shock-absorbing switch points

dampen the effects of vibration while maintaining

performance.

Set Point Accuracy—Standard high-resolution set

point adjustments are easy to set, non-interactive,

and can be locked in place to maintain the desired

set point. The optional set point indication

assemblies on the front panel are easy to read and

let you simply dial in the desired set point.

Figure 2. Fisher 4660 High-Low Pressure Pilot with

Block and Bleed Relay; Left Side with Case Cover Off

SET POINT ADJUSTMENTS

X0232

BOURDON TUBE

BLOCK AND

BLEED RELAY

Easy Maintenance—Simple modular construction

plus a line of prepackaged parts kits makes pilot

maintenance fast and easy.

Installation Versatility—Panel, rack, pipestand, or

actuator mounting is available to meet field

requirements.

Operational Indications—A supply pressure test

function is provided. The optional output indicator

lets you check at a glance whether the pilot output

pressure is at full output or zero output pressure.

Available Configurations

High-low, low-only, or high-only set point

capability

Input Signal

Type: Process pressure sensed with a Bourdon tube

Bourdon Tube Ratings: See table 1 or 2

Overpressure Protection: Maximum allowable

emergency process pressures and maximum

allowable process pressures to ensure set point

readjustability are shown in table 3

Output Signal

Zero pressure or full supply pressure

(automatically resets)

Supply Pressure(1)

Normal Operating Pressure: 1.4 to 4.4 bar

(20 to 65 psig)

Medium: Air or Natural Gas

Supply medium must be clean, dry, and noncorrosive

Steady-State Air Consumption(2)

Output Signal at 0 psig: ≤0.134 normal m3/hr

(≤5 scfh)

Output Signal at Full Supply Pressure:

≤0.00134 normal m3/hr (≤0.05 scfh)

Set Point Adjustments

Continuously adjustable between 3% and 97% of

Bourdon tube rating; see table 1 or 2 for ranges

Performance in Percentage of Bourdon Tube Rating

Repeatability: ≤0.25%

Set Point ΔPmin .

(See table 1 or 2)

Single High-Low Unit: 10% for up to 170 bar (2500

psig) Bourdon tubes; 15% for 350. 500. and 700

(NACE) bar (5000. 7500. and 10.000 (NACE) psig)

Bourdon tubes

Low-Only and High-Only Pair: 3%

Trip-to-Reset Zone: ≤1.5% (see table 1 or 2)

Exhaust Capacity

Cg ≥15

Construction Materials

Case and Cover: Polyester

Front Cover: Tinted polycarbonate with

scratch-resistant coating

Base: Hard-anodized nickel-sealed aluminum alloy

Bourdon Tube: S31600 SST or NACE compliant

material

Relay Body, Relay Flange, Nozzle/Flapper Assembly

Orifice Block, and Switch Point Housings: Glass-filled

polyphenylene sulfide

Relay Diaphragm: Fluorosilicone/Polyester

Relay Discs: Fluorosilicone

Process Pressure Block, Tubing, Front Plate, Flapper,

Linkages, and Other Major Metal Parts: Stainless steel

Gaskets: Chloroprene and nitrile

O-Rings.

Relay: Nitrile

Switchpoint Assembly: Nitrile impregnated with

molybdenum disulphide

Base/Case: Nitrile

Operating Conditions(1)

Condition

Normal Operating Limits

Ambient

Temperature-59 to 71C (-75 to 160F)

Nominal

Reference

21C (70 F)

Operating Influences on Switch Point Sensitivity

Supply Pressure: ≤0.05% of Bourdon tube rating for a

10% change in supply pressure

Ambient Temperature: ≤2% of Bourdon tube rating

throughout normal operating limits with nominal

reference

Time: ≤1% of Bourdon tube rating over 30 days at

ambient temperature nominal reference

Process Pressure: Range shift or set point drift can

occur if process pressure exceeds the Bourdon tube

rating

Pressure Connections

1/4 NPT internal

Mounting

Panel,

rack,

pipestand, or actuator

Specifications (continued)

Hazardous Area Classification

Complies with the requirements of ATEX Group II

Category 2 Gas and Dust

Ex h IIC Tx Gb

Ex h IIIC Tx Db

Maximum surface temperature (Tx) depends on

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|