WOODWARD Load Sharing Module 0.5–4.5 Vdc Output 9907-252

Load Sharing Module

0.5–4.5 Vdc Output

9907-252

The Woodward Load Sharing Module is made for use with engines equipped with speed controls that

accept a 0–5 Vdc speed setting. The Load Sharing Module allows use of Woodward power generation

accessories and allows load sharing between engines equipped with speed controls that are not

manufactured by Woodward and engines controlled with Woodward electronic controls, or controls using

other Woodward load sharing modules.

Description

The Load Sharing Module provides isochronous and droop load-sharing capability for engines in

generator set applications. Additional equipment in the control system can include the Woodward SPM-A

Synchronizer, Import/Export Control, Automatic Generator Loading Control, and Automatic Power

Transfer and Loading Control.

Introduction

This section contains general installation instructions for the Load Sharing Module. Environmental

precautions and location considerations are included to determine the best location for the Load Sharing

Module. Additional information includes unpacking instructions, electrical connections, and an installation

check-out procedure.

Unpacking

Before handling the Load Sharing Module, read page ii, Electrostatic Discharge Awareness. Be careful

when unpacking the Load Sharing Module. Check the unit for signs of damage such as bent or dented

panels, scratches, and loose or broken parts. Notify the shipper of any damage.

Location Considerations

Consider these requirements when selecting the mounting location:

• Adequate ventilation for cooling

• Space for servicing and repair

• Protection from direct exposure to water or to a condensation-prone environment

• Protection from high-voltage or high-current devices, or devices which produce

electromagnetic interference

• Protection from excessive vibration

• An ambient operating temperature range of –40 to +70 °C (–40 to +158 °F)

Do not mount the Load Sharing Module on the engine.

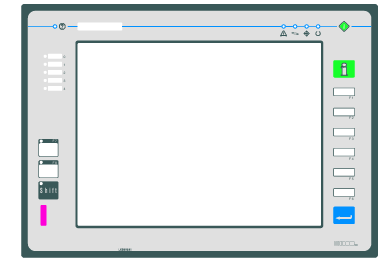

Figure 1-2 is an outline drawing of the Load Sharing Module. Install the unit as close as practical to the

electronic engine control, but not on the engine itself. It may be installed in any position.

To maintain compliance with CE and UKCA marking requirements, the European Union Low Voltage

Directive requires that the Load Sharing Module (LSM) be mounted in an IP43 enclosure as defined in

EN60529. Access to the Load Sharing Module must be restricted to qualified personnel.

General Wiring Requirements

The circled ground symbol identifies the Protective Earth Terminal. This terminal must be

connected directly to protective earth using a grounding conductor at least as large as those

used on terminals 1 through 9. The insulation of the grounding conductor must be of green and

yellow color.

This symbol identifies functional or EMC earth. This terminal is to be used for cable shield

connections only. It is not to be used as a protective earth terminal.

External wiring connections and shielding requirements for a typical installation are shown in the plant

wiring diagram, Figure 1-4. These wiring connections and shielding requirements are explained in more

detail in this chapter.

To maintain compliance with CE and UKCA marking requirements, the Low Voltage Directive requires

that the Load Sharing Module must only be connected to Class III equipment.

Wiring for the Load Sharing Module must be suitable for at least 90 °C (194 °F) and also be suitable for

the maximum installed operating temperature.

The Load Sharing Module must be permanently connected and employ fuses or circuit breakers in each

of the PT lines to limit current to the LSM PT inputs to no more than 5 A. In addition, a 2 A fast-acting fuse

or circuit breaker must be provided in the 24 Vdc power supply line.

All terminal block screws must be tightened to 0.56 to 0.79 N·m (5.0 to 7.0 lb-in).

To maintain compliance with CE and UKCA marking requirements, the EMC Directive requires that all

shields be connected to the terminals provided per the plant wiring diagram, Figure 1-4.

Power Requirements

The Load Sharing Module is powered from a 24 Vdc source. The 24 Vdc source must be a minimum of

18 Vdc and a maximum of 32 Vdc continuous. If a battery is used for operating power, an alternator or

other battery charging device is necessary to maintain a stable supply voltage.

Shielded Wiring

All shielded cable must be twisted conductors with either a foil or braided shield. Do not attempt to tin (put

solder on) the braided shield. All signal lines should be shielded to prevent picking up stray signals from

adjacent equipment. Connect the shields to the terminals indicated in the plant wiring diagram. Wire

exposed beyond the shield must be as short as possible.

The other end of the shields must be left open and insulated from any other conductor. Do not run

shielded signal wires with other wires carrying large currents. See Application Note 50532. EMI Control

for Electronic Governing Systems, for more information.

Where shielded cable is required, cut the cable to the desired length and prepare the cable as instructed

below and shown in Figure 2-1.

Introduction

This chapter describes the operation of the Load Sharing Module and its internal circuits. Figure 1-3 is a

block diagram of the circuits in the module.

The Load Sharing Module senses the power output of a generator and provides a 0.5–4.5 Vdc signal to

the speed control to adjust the power output of the engine-generator set to match the reference power

level. The Load Sharing Module can also produce a droop condition (instead of isochronous load

sharing), making it possible to connect the generator set in parallel with either a generator set which is

running isochronously, or with an infinite bus.

Power Supply

The internal power supply generates a regulated dc voltage for the operation of the circuits in the Load

Sharing Module. The power supply gets its power from the engine 24 Vdc power source. To prevent

damage to the unit that uses an alternator or battery charging device, make sure the charging device is

turned off before disconnecting or connecting the 24 Vdc supply to the unit.

Power Sensor

Generator load is measured by the power-sensor circuit of the Load Sharing Module. The power-sensor

circuit senses current amplitude and produces a load signal proportional to the current amplitude times

the power factor. The potential input comes from potential transformers (PTs) and the current input comes

from the current transformers (CTs). The circuit uses these two inputs to generate a load signal which is

then filtered and sent to the controller circuit. The load signal voltage of each generator set will be

proportional to the percentage of rated load on the generator set.

Ammeters and voltmeters may be driven with the same PT and CT wires.

Load Comparator Circuit

In the load comparator circuit, the load signal voltage is balanced with the other generator sets in the system via

the load sharing lines. The comparator circuit of each Load Sharing Module includes a load gain potentiometer to

adjust each generator set's load signal so that the load signal voltage of each is the same at full load. This

compensates for varying CT ratios or different generator set sizes. The load sharing voltage will be one-half the

measured voltage of the load signal test point.

Speed Trim Circuit

A speed-trim potentiometer can be added to the Load Sharing Module to permit remote adjustment of the

load or frequency of the generator. The speed trim is normally used for manual synchronization of a

generator set with an existing bus or to change the load demand when in droop mode.

Isochronous Load Sharing

Each comparator circuit compares the load signal voltage for its generator set to two times the voltage on

the load sharing lines and produces an error voltage proportional to the difference. This error voltage is

used to generate a pulse width modulated signal which is output to the speed control. This output biases

the speed loop of the speed control until the load signal voltage is equal to that of other generators on the

load sharing lines.

Droop Operation

In droop operation, a portion of the load signal voltage is fed to the controller circuit. This voltage is used

by the comparator circuit to reduce the control output by a percentage determined by the DROOP

potentiometer. The output is reduced, and the speed control reduces engine power output according to

the desired droop percentage.

When a generator set using the Load Sharing Module is paralleled in droop with other generator sets, the

common load signal on the paralleling lines is not used. The frequency of the generator set will therefore

vary with load, so it must be determined by a different means. In an isolated system with two or more

generator sets paralleled, if isochronous speed control is required, one of the generator sets must be

running in the isochronous (constant speed) mode. This generator set maintains the frequency of the

system. If a generator set is in droop and is paralleled with an infinite bus, the bus determines and

maintains the frequency. The DROOP percentage and the speed setting on the engine speed control

determine the amount of the load that is carried by the generator, when running in droop.

Auxiliary Equipment

The Woodward SPM-A synchronizer functions by biasing the output of the Load Sharing Module. All other

Woodward auxiliary generating control equipment functions by biasing the voltage on the load-sharing

lines.

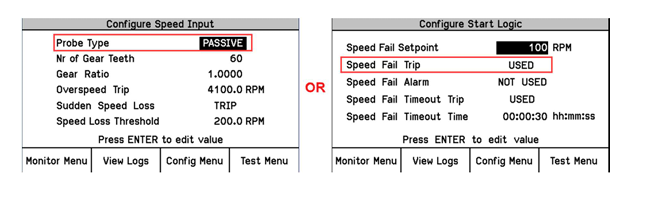

0.5–4.5 Vdc Output

The Load Sharing Module output to the engine control is a 0.5 to 4.5 Vdc signal. The output nominally is

at 2.5 Vdc when the difference between the generator load and the signal on the load sharing lines is

zero.

The speed control should be set up in Variable Speed Governor mode to produce a ±10% variance in the

engine speed with a ±2.0 Vdc input, as shown in this example:

If 1800 rpm is equivalent to 60 Hz for a ±5.0% variance on the speed of the engine, the control would be

set up such that 0.5 Vdc output corresponds to 1710 rpm (VSG MIN

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|