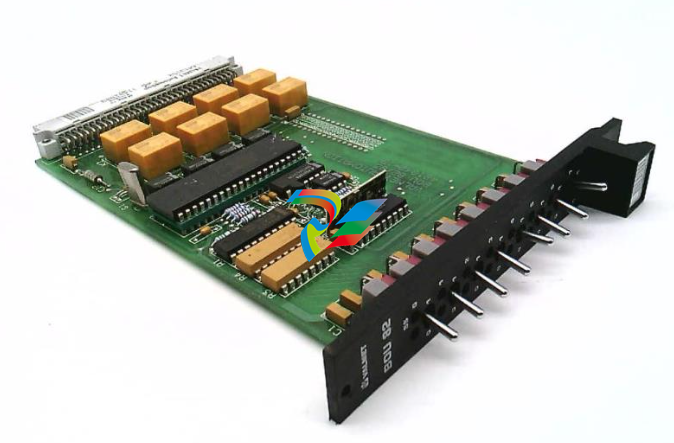

METSO A413152 High-performance pneumatic relay

The Metso (now Neles/Valmet) A413152 is a specialized Pneumatic Relay / Pilot Valve Assembly, specifically designed as a core component for the Neles ND9000 series intelligent valve positioners.

It serves as the physical interface that converts electronic signals into pneumatic power to move the valve actuator.

1. Product Description

The A413152 is a high-performance pneumatic relay.

In the architecture of an intelligent positioner, the electronic circuit board (like the A413140) calculates the required movement, but it is the A413152 relay that actually directs the compressed air to the actuator chambers.

It is a "pre-amplifier" stage that allows a very small electrical signal to control a large volume of high-pressure air with extreme precision.

Its design focuses on high dynamic response and minimal air consumption during steady-state operation.

2. Technical Parameters (Technical Data)

| Parameter | Specification |

| Component Type | Pneumatic Relay / Amplifier Module |

| Supply Pressure Range | 1.4 – 8.0 bar (20 – 115 psi) |

| Air Delivery Capacity | Optimized for fast stroking (approx. 8–18 $Nm^3/h$ depending on supply) |

| Steady-state Air Consumption | Very Low (< 0.1 $Nm^3/h$ at 4 bar) |

| Operating Medium | Filtered, non-lubricated air or sweet natural gas |

| Filtration Requirement | < 40 $mu m$ (5 $mu m$ recommended for longevity) |

| Temperature Range | -40°C to +85°C (-40°F to +185°F) |

| Housing Material | High-grade Aluminum with corrosion-resistant coating |

3. Product Advantages & Key Features

High Dynamic Response: Enables the valve to react instantly to small setpoint changes, essential for stable process control.

Low Bleed Design: Significantly reduces the "instrument air" overhead costs by minimizing air leakage when the valve is in a fixed position.

Modular "Plug-in" Installation: The relay is designed as a single block that can be replaced by removing a few screws, without needing to dismantle the entire positioner or disconnect main air lines.

Contamination Resistance: Features integrated fine-mesh filters to protect the sensitive internal pilot stage from particles in the air supply.

Balanced Design: Operates reliably even if there are slight fluctuations in the plant's main air supply pressure.

4. Application Cases

High-Frequency Modulation: Used in control loops that require constant adjustment, such as pressure-reducing stations or turbine steam control.

Fast-Acting Safety Valves: Integrated into systems requiring rapid "Fail-Safe" action upon signal loss.

Remote Gas Pipelines: Because of its low steady-state air consumption, it is ideal for sites using bottled gas or solar-powered compressors where gas/air volume is limited.

Corrosive Environments: Found in offshore oil platforms and chemical plants where internal components must resist salt air and chemical vapors.

5. Related & Other Models in the Series

The A413152 is part of the modular pneumatic ecosystem of the ND9000:

ND9100 / ND9200: The standard and high-flow intelligent positioners that utilize this relay.

A413120: A similar pneumatic relay module (check serial number compatibility for specific flow requirements).

A413150: A standard version of the relay assembly; the A413152 often represents a specific revision or high-performance variant.

B1-Series Actuators: The pneumatic cylinders/diaphragms typically powered by this relay.

Filter Regulator (e.g., Neles K-series): The necessary upstream component required to protect the A413152 from moisture and debris.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|