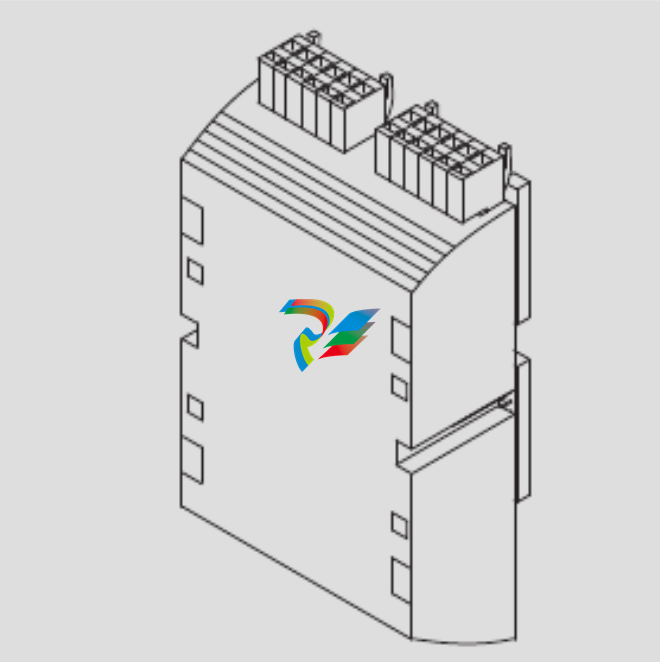

Lenze EPZ-10203 Hardware expansion board

a high-functionality expansion module specifically designed for the Lenze Global Drive PLC (EPL-10200 series) and compatible 9300/8200 series drives.

1. Product Description

The EPZ-10203 is a hardware expansion board that plugs directly into a Lenze Drive PLC (such as the EPL-10200).

Its primary purpose is to extend the input/output capabilities of the drive-based control system, allowing it to handle more complex automation tasks without needing a separate, large-scale cabinet PLC.

Role: Decentralized I/O expansion.

Mounting: Plugs into the Drive PLC via two 26-pin headers.

System Integration: Automatically recognized by the Drive PLC Developer Studio (DDS) software upon power-up.

2. Technical Parameters

| Parameter | Specification |

| Supply Voltage | 24 V DC (typically sourced from the Drive PLC) |

| Current Consumption | Max. 4 A (at maximum load of all outputs) |

| Digital Inputs | 8 Inputs (standard 24V logic) |

| Digital Outputs | 4 Outputs (24V DC, high-current capacity up to 1 A per output) |

| Enclosure Rating | IP20 |

| Operating Temp | 0°C to +40°C (up to +55°C with power derating) |

| Connection Type | Multi-pin header for PLC coupling; screw terminals for field wiring |

| Weight | Approx. 0.75 kg |

3. Product Advantages & Features

Plug-and-Play Setup: Once connected, the additional I/O are immediately available for use in the IEC 61131-3 programming environment.

High Output Power: Unlike standard logic outputs, these can drive up to 1 Amp, allowing direct control of smaller solenoids or contactors without interposing relays.

Space Saving: Eliminates the need for external I/O racks by integrating the logic and expansion directly onto the drive.

Real-time Response: Since it is physically coupled to the Drive PLC, there is no communication bus latency (like Profibus/Ethernet) for these local I/O points.

4. Application Cases

Flying Saw / Rotary Cutters: Using the additional digital inputs for high-speed mark detection and the outputs for triggering pneumatic actuators.

Bottle Filling Plants: Coordinating complex cam profiles and valve timing directly at the motor station.

Winding Machines: Managing dancer arm limit switches and brake controls locally.

Machine Upgrades: Adding extra sensors and actuators to an existing Lenze 9300/8200 setup without redesigning the main control panel.

5. Related & Other Models in the Series

The EPZ-10203 is part of a modular family of expansion boards:

EPL-10200-XX: The host Drive PLC module required to run the EPZ board.

EPZ-10201 (Extension Board 1): A standard I/O extension with different input/output counts.

EPZ-10202 (Extension Board 2): Typically features specialized analog or high-speed counter functions.

EMZ-9374IB: Terminal extension for the system bus (CAN).

EMF-2173IB: PC system bus converter (used for connecting a PC to the Drive PLC for programming).

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|