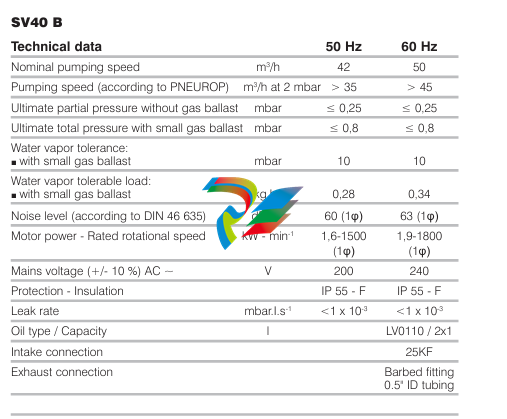

LEYBELOD SV40 BI Single-stage, oil-sealed rotary vane pump

Description

Sogevac® pumps are designed for pumping of inert gases in the range of

rough vacuum, between atmospheric pressure and ultimate pressure of the

pump.

When removing condensable vapors, periodic opening of the gas ballast

valve is required.

1.1 Principle of operation

The Sogevac® pumps SV40 BI are single-stage oil-sealed rotary vane

vacuum pumps.

The rotor, having three slots in which the vanes are sliding, is eccentrically

installed in a pump cylinder (stator).

The vanes separate the interior space into 3 chambers. The volume of these

chambers varies with the rotation of the rotor.

The gas sucked into the inlet chamber is compressed and then pushed out

at the exhaust valve.

.png)

The oil injected in the inlet chamber guarantees the air-tightness, the

lubrication and cooling of the pump. It is dragged off by the compressed

gases and roughly separated by gravity when entering in the oil sump. A fine

separation is then operated in the exhaust filter. An internal transfer pushes

the collected oil back into the vacuum generator, the transfer is operated by

a float valve to avoid atmospheric air coming from the oil casing to the inlet

of the pump when no oil is present in the recovery system.

The oil circulation functions by differential pressures.

The pumps are equipped with a gas ballast valve for pumping condensable

vapors.

The anti suckback valve at the inlet flange avoids oil coming back into the

inlet line when the pump is stopped. This is valid for working pressures below

100 mbar and under the condition that the valve is kept clean and in good

condition. The anti suck

back valve is not a safety valve. If oil back flowing is to be avoided by all

means, it is necessary to mount a separate safety valve on the pump inlet

The preferred rough pump in the analysis application

Leybold SOGEVAC BI and DI are the preferred oil-sealed rotary vane pumps for analytical applications due to their optimal ultimate pressure, high pumping speed and single-phase drive.

Its reliability, low NIos and maintenance-free operation are additional advantages for applications such as mass spectrometry with pumping speeds ranging from 16 to 147 meters per hour.

OEM manufacturers offer customized variants for various analytical instruments.

The rotor has three slots, into which the blades can slide and is eccentrically installed in the pump cylinder (stator).

These leaves divide the interior space into three rooms. The volume of these chambers varies as the rotor rotates.

The gas drawn into the intake chamber is compressed and then discharged through the exhaust valve.

The oil injected into the intake chamber ensures the airtightness, lubrication and cooling of the pump. It is dragged away by compressed gas and roughly separated by gravity

The maintenance time for LC or GC multiple sclerosis can reach up to 24.000 hours

Integrated oil recovery system and anti-suction valve

Low and pleasant noise level

Optimize integrated lubrication without the need for external pipelines

According to EN 61010-1. different single-phase drives with overload protection

Compact, smooth design and small floor space

GENIUS Instant Insights™ provides you with actionable insights to help you prevent common pump failures, including mechanical failures, contamination and improper Settings.

By maximizing operating time, reducing maintenance costs and providing round-the-clock accessibility, GGENIUS ensures the efficient operation of pumps.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|