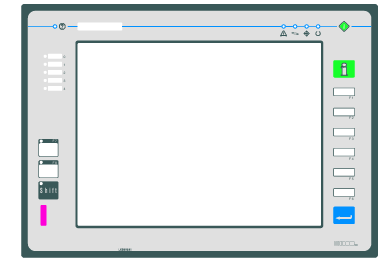

ALSTOM D-984 0584 - 2/4 Flame & Fault Alarm Board

The ALSTOM D-984 0584 stands out as a highly robust and versatile automation component designed specifically for demanding environments in the power industry, petrochemical sector, and general automation applications. Engineered with precision, this model offers exceptional input/output capacity, high durability, and reliable performance metrics, making it a preferred choice for complex industrial automation systems.

Key technical features of the ALSTOM D-984 0584 include an enhanced input/output interface capable of handling extensive signal processing with high accuracy. It supports a wide range of analog and digital inputs, ensuring seamless integration with diverse sensors and control devices. With a ruggedized construction, the D-984 0584 is built to endure harsh environmental conditions such as extreme temperatures, vibrations, and electrical noise, which are common in power plants and petrochemical facilities. Its performance metrics highlight a rapid response time and minimal latency, crucial for real-time automation control and critical safety functions.

In real-world scenarios, the ALSTOM D-984 0584 excels in applications requiring precise control and monitoring over complex process parameters. For example, in power generation plants, it manages turbine controls, generator protection, and system diagnostics efficiently. In petrochemical processing, it ensures accurate measurement and regulation of pressure, temperature, and flow rates, contributing to operational safety and optimization. Its reliability also extends to general automation systems where continuous uptime and fault tolerance are mandatory, such as in manufacturing lines and infrastructure management.

When compared to other ALSTOM automation products, the D-984 0584 distinguishes itself through its combination of high input/output density and rugged industrial design. Unlike the ALSTOM GEM80, which is optimized primarily for general automation tasks with moderate input/output needs, the D-984 0584 supports more complex configurations and higher data throughput. Meanwhile, models like the ALSTOM MICOM P122 specialize in protection relays for electrical networks but do not offer the same broad automation interface as the D-984 0584. Additionally, the ALSTOM PS 421 provides power supply solutions that complement the D-984 0584 by ensuring stable power delivery, but it lacks the processing and I/O capabilities inherent in the D-984 0584.

Alongside the ALSTOM D-984 0584, several related ALSTOM models enhance its functionality in integrated automation setups. The ALSTOM DW02 and ALSTOM ALSPA C80-75 IC697PWR713J provide additional control processing and power management capabilities, making them ideal companions for complex automation architectures. For enhanced safety and diagnostics, the ALSTOM PIB100G and ALSTOM Power MP-7848 offer specialized monitoring and protection functions that can be seamlessly integrated with the D-984 0584. The ALSTOM IC693PWR324X power supply unit complements the product by delivering reliable power under fluctuating industrial conditions. For applications requiring user interface and operational control, units such as the ALSTOM JOYSTICK CONTROLLER STATION and ALSTOM Micom P139 fit well within the ecosystem, providing intuitive control and communication interfaces.

The ALSTOM D-984 0584 is designed with scalability in mind, allowing it to work in harmony with other ALSTOM automation products such as the ALSTOM PS431 and ALSTOM Utility Modul 43297-029, which extend system capabilities in power and process control. Furthermore, the model’s compatibility with the ALSTOM Control Techniques line enhances its versatility in motor control and drive applications, rounding out its suitability for comprehensive industrial automation projects.

In conclusion, the ALSTOM D-984 0584 blends superior technical specifications with robust industrial design, making it an indispensable component for the application of D-984 0584 in power industry, petrochemical, and general automation environments. Its ability to integrate smoothly with complementary ALSTOM models like the GEM80, MICOM P122, PS 421, DW02, and PIB100G ensures a scalable and reliable solution tailored to the most demanding automation needs. For organizations seeking advanced ALSTOM automation products that deliver both performance and durability, the D-984 0584 represents a strategic investment that guarantees operational excellence and long-term reliability.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|