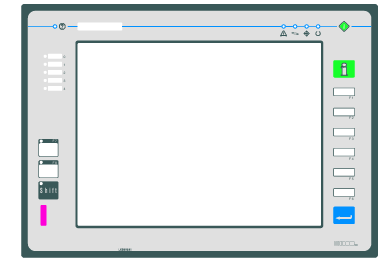

ALSTOM MAE 00-11 - I/O termination panel AVE248520

The ALSTOM MAE 00-11 is a high-performance automation product specifically engineered for demanding environments within the power industry, petrochemical plants, and general automation sectors. Renowned for its robust design and reliable operation, the MAE 00-11 delivers superior input/output (I/O) capacity and exceptional durability, making it an indispensable component in complex automated systems.

At its core, the ALSTOM MAE 00-11 boasts a versatile I/O configuration that supports extensive data acquisition and precise control functionalities. It integrates both analog and digital inputs and outputs, enabling seamless interfacing with a broad spectrum of field devices and sensors. This capability ensures real-time monitoring and control, which is critical in power generation units, refinery automation, and industrial process control. Performance-wise, the MAE 00-11 operates with high-speed processing and minimal latency, supporting rapid response times essential for safety-critical applications. Its rugged construction ensures resilience against harsh industrial conditions, including temperature fluctuations, vibration, and electromagnetic interference, thereby guaranteeing consistent operation over extended periods.

In practical use, the ALSTOM MAE 00-11 excels in environments where stability and precision are paramount. Within the power industry, it functions effectively in turbine control systems, grid management automation, and protective relaying. Petrochemical facilities benefit from its ability to handle complex process control scenarios, such as temperature regulation, pressure monitoring, and safety interlocks. For general automation, the MAE 00-11 adapts to manufacturing line controls, automated material handling, and building management systems, offering a flexible solution that can be tailored to specific operational needs.

When compared to other ALSTOM models, the MAE 00-11 stands out due to its balanced combination of scalability and ruggedness. Unlike the ALSTOM VTT11ZG8050LCH, which is primarily designed for high-voltage switchgear control with specialized protocols, the MAE 00-11 offers broader I/O versatility suited to multifaceted automation tasks. Compared to the ALSTOM PIB504, known for compact design but limited I/O expansion, the MAE 00-11 provides enhanced modularity that supports system growth without compromising performance. Additionally, models like the ALSTOM SKE11BF8003BCH focus on specific signaling applications, whereas the MAE 00-11 delivers comprehensive input/output management, making it more versatile for integrated automation solutions.

Alongside the ALSTOM MAE 00-11, ALSTOM offers a range of complementary automation products to meet diverse operational demands. For example, the ALSTOM AL129A and ALSTOM PIB201A modules facilitate specialized signal conditioning and interface tasks that augment the MAE 00-11’s capabilities. The ALSTOM 20X4249A4 and ALSTOM 31v6900/10 provide additional processing power and communication options for complex networked systems. The ALSTOM UT129A-5 module supports enhanced diagnostic and monitoring functions, which can be paired with the MAE 00-11 for improved system oversight. Moreover, the ALSTOM Dynamic Positioning Joystick Controller Series DP and ALSTOM MVS3000-4011 represent advanced control interfaces and supervisory units that complement the automation ecosystem built around the MAE 00-11. For power system grounding and safety, the ALSTOM FF310 BRONZE CROSSWAR BUSHING offers reliable protection components that work synergistically within the infrastructure where the MAE 00-11 operates.

The application of the ALSTOM MAE 00-11 in power industry, petrochemical, and general automation sectors is further enhanced by its seamless integration with ALSTOM’s broader portfolio of automation products. This integration ensures that operators benefit from streamlined installation, standardized communication protocols, and centralized control strategies. Additionally, the durability and high-performance metrics of the MAE 00-11 reduce maintenance costs and downtime, delivering long-term value in mission-critical operations.

In summary, the ALSTOM MAE 00-11 represents a cornerstone product within ALSTOM automation products, combining versatile I/O capacity, robust durability, and high-speed performance tailored for challenging industrial environments. Its unique advantages over other ALSTOM models, such as enhanced modularity and broader application scope, make it the preferred choice for power industry automation, petrochemical process control, and general automation tasks. Supported by a comprehensive family of complementary ALSTOM modules like the ALSTOM VTT11ZG8050LCH, ALSTOM PIB201A, ALSTOM Dynamic Positioning Joystick Controller Series DP, and ALSTOM FF310 BRONZE CROSSWAR BUSHING, the MAE 00-11 ensures reliable, precise, and scalable automation solutions for modern industrial challenges.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|