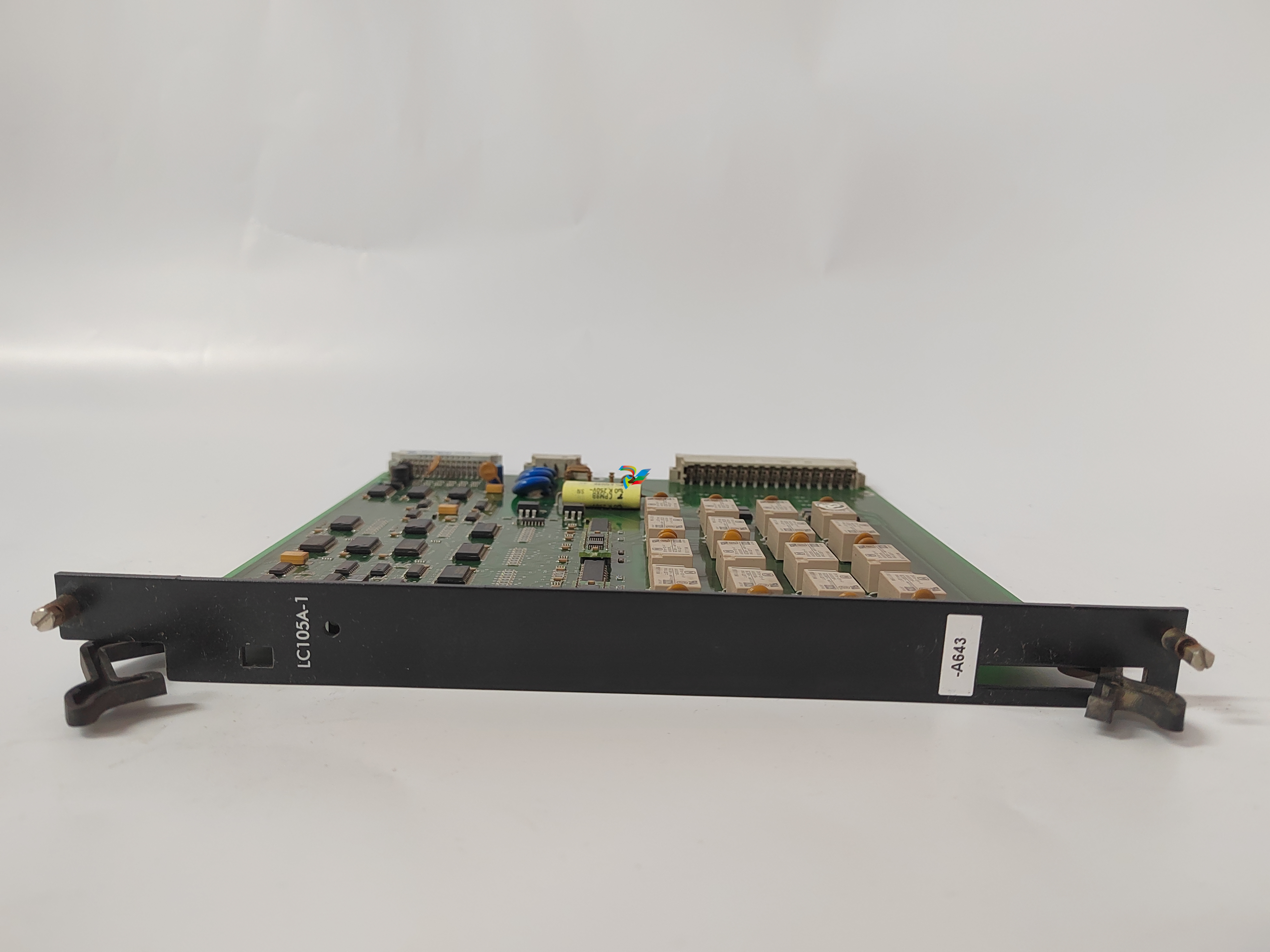

ALSTOM R222(A0)1161/64 - GASKET STK# 31606 J-5 18 INCH X 13 INCH

The ALSTOM R222(A0)1161/64 is a robust automation component specifically engineered to meet the demanding requirements of the power industry, petrochemical sector, and general automation applications. This model exemplifies ALSTOM’s commitment to delivering reliable, high-performance solutions that optimize operational efficiency while ensuring long-term durability in harsh industrial environments.

At its core, the ALSTOM R222(A0)1161/64 features a versatile input/output capacity designed to seamlessly integrate with complex control systems. It supports multiple signal types, ensuring compatibility with a wide array of sensors and actuators commonly used in power generation and petrochemical processing plants. This flexibility enables precise control and monitoring of critical parameters, such as temperature, pressure, and flow, essential for maintaining safe and efficient operations.

Durability is a defining characteristic of the R222(A0)1161/64, crafted from high-grade materials that resist corrosion and wear even in chemically aggressive or high-temperature environments. Its rugged design extends service life and reduces maintenance intervals, making it a cost-effective choice for continuous industrial use. Performance metrics reveal its exceptional response times and reliable signal integrity, crucial for automation systems requiring real-time data processing and rapid actuation.

In real-world scenarios, the ALSTOM R222(A0)1161/64 excels in applications such as turbine control in power plants, where precise modulation of fuel and airflow is vital for optimizing combustion efficiency and reducing emissions. It is equally effective in petrochemical plants, managing complex chemical reaction processes that demand stringent control to maintain product quality and safety. Additionally, its adaptability in general automation systems makes it ideal for factory automation, process control, and infrastructure monitoring tasks, where consistency and accuracy are paramount.

When compared to other models within the ALSTOM range, the R222(A0)1161/64 stands out for its superior input/output versatility and enhanced environmental resistance. For instance, while the ALSTOM PIB310 and ALSTOM RTx-151 offer robust automation capabilities, the R222(A0)1161/64 provides improved integration options and a more compact footprint, facilitating easier installation in confined control panels. Moreover, unlike the ALSTOM Auxiliary Relay and ALSTOM Brown Boveri HTGR001E65P0007, which focus on specific relay or power conversion tasks, the R222(A0)1161/64 delivers a broader functional scope suitable for multi-purpose automation needs.

Alongside the ALSTOM R222(A0)1161/64, we also offer complementary products such as the ALSTOM LC106-1 - B0002166, known for its precision control modules; the ALSTOM scn666 and ALSTOM scn804 d, which provide advanced signal conditioning; and the ALSTOM Module C1003140, ideal for system expansion and customization. The ALSTOM Converteam PIB-201A and ALSTOM Power Conversion units further enhance the automation ecosystem by delivering efficient power management solutions. For specialized applications, the ALSTOM GECOSTAT MC15-M2 and ALSTOM CHECK SYNCHRONISING devices ensure system stability and synchronization, critical in power generation contexts.

The application of R222(A0)1161/64 in the power industry, petrochemical, and general automation sectors underscores its adaptability and performance. Its ability to handle complex control signals with minimal latency and high accuracy makes it a backbone component in sophisticated automation architectures. Whether integrated within a large-scale power plant control room or embedded in a petrochemical process control system, this ALSTOM model guarantees operational excellence.

By choosing ALSTOM automation products such as the R222(A0)1161/64, users benefit from a legacy of engineering excellence and comprehensive support from a globally recognized brand. This model, together with related products like the ALSTOM 8RDC44667G01, ALSTOM RTS-61, and ALSTOM Micom M300, creates a cohesive automation platform that addresses the evolving needs of industrial automation with reliability and precision.

In summary, the ALSTOM R222(A0)1161/64 is a highly versatile and durable automation device tailored for critical industrial applications. Its advanced technical features, combined with proven performance in power, petrochemical, and general automation environments, make it an indispensable asset for operators seeking to enhance control accuracy and system reliability. By integrating this model with other ALSTOM automation products, industries can achieve seamless, efficient, and scalable automation solutions designed to meet today’s challenges and tomorrow’s innovations.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|