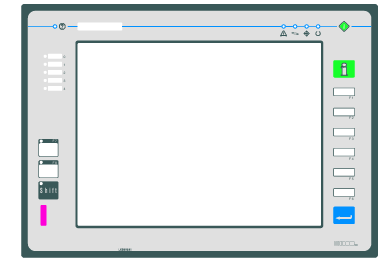

Honeywell RT10A - "- 25.6cm (10.1"") - 1920 x 1200 Pixels - 32GB - 4GB"

The Honeywell RT10A is a robust and versatile automation controller engineered to meet the demanding requirements of the power industry, petrochemical plants, and general automation applications. Known for its exceptional input/output (I/O) capacity, durability, and reliable performance, the RT10A stands as a cornerstone in Honeywell’s extensive portfolio of automation solutions.

At the core of the Honeywell RT10A’s technical capabilities is its superior I/O handling, designed to seamlessly manage complex control processes. It supports a wide range of analog and digital input/output modules, providing scalability and flexibility to meet specific operational needs. This makes the RT10A ideal for systems requiring precise monitoring and control, such as turbine control in power plants or critical process automation in petrochemical facilities. Its rugged construction ensures operational stability in harsh environments, with resistance to temperature extremes, vibration, and electromagnetic interference—key factors in ensuring continuous uptime in industrial settings.

Performance-wise, the RT10A excels with fast processing speeds and high reliability, minimizing latency in control loops and enabling real-time data acquisition and response. This performance metric is critical in scenarios like load balancing in power grids or safety shutdown sequences in chemical plants, where milliseconds can impact operational safety and efficiency. The RT10A’s embedded diagnostics and fault-tolerant architecture further enhance its dependability, reducing maintenance downtime and ensuring continuous process integrity.

In real-world applications, the Honeywell RT10A shines in power industry automation by providing stable and precise control of generators and substations. In petrochemical plants, it manages complex distillation and refining processes, integrating smoothly with other control systems to maintain optimal throughput and safety. Its adaptability also suits general automation needs, from manufacturing lines to infrastructure management, where reliable, high-speed control and data handling are paramount.

Compared to other Honeywell automation products such as the Honeywell WEB-8100-U or the Honeywell PC700, the RT10A offers a more specialized solution focused on high I/O density and real-time control performance. While the WEB-8100-U excels as a user interface terminal and the PC700 serves as a robust process controller, the RT10A combines these strengths with enhanced durability and scalability for mission-critical environments. Similarly, models like the Honeywell 4204 and Honeywell FC-PDIO01 provide modular I/O functions but lack the integrated processing power and rugged design that characterize the RT10A. This makes the RT10A uniquely suited for demanding industrial automation scenarios where both control precision and environmental resilience are non-negotiable.

Alongside the Honeywell RT10A, Honeywell offers complementary products such as the Honeywell MCDU860 for advanced monitoring, the Honeywell 620-0073C for specialized sensor integration, and the Honeywell AD650, which provides enhanced analog input capabilities. The Honeywell 51402089-100 and Honeywell 51198801-100 modules extend the I/O capacity for larger systems, while the Honeywell CC-PUIO31 and Honeywell TSENAL-MOX-06514 serve critical roles in signal conditioning and system interfacing. For system-wide automation management, the Honeywell BAS platform integrates seamlessly with the RT10A, making it an indispensable part of comprehensive process control solutions.

When considering the application of RT10A in power industry, petrochemical, and general automation, the product’s resilience and performance set it apart. It stands as the preferred choice for engineers and system integrators who demand not only superior technical specifications but also proven reliability over extended operational cycles. The Honeywell RT10A’s design philosophy emphasizes modularity, ease of maintenance, and backward compatibility with legacy Honeywell systems, ensuring smooth upgrades and minimal disruption during deployment.

In summary, the Honeywell RT10A is a high-performance automation controller that offers unparalleled I/O capacity, rugged durability, and reliable operation in the most challenging industrial environments. Its advantages over other Honeywell models make it an ideal solution for critical applications within the power industry, petrochemical sector, and general automation fields. Combined with complementary products like the Honeywell WEB-8100-U, PC700, MCDU860, and BAS, the RT10A forms a core component of Honeywell’s comprehensive suite of automation products. For professionals seeking dependable, scalable, and efficient control systems, the Honeywell RT10A remains a trusted choice.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|