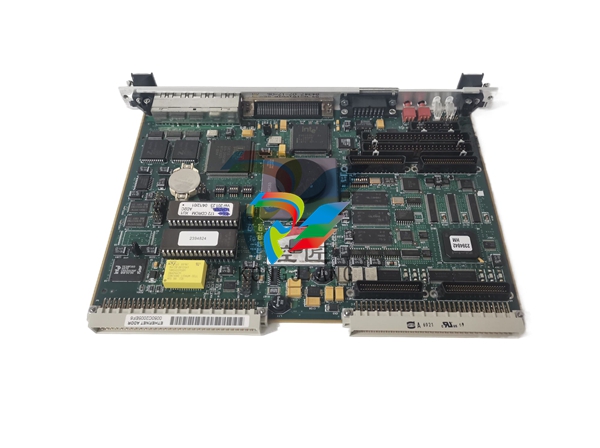

Part Number IS230TBAI1CG01 Manufacturer General Electric Country of Manufacture As Per GE Manufacturing Policy Series Mark VI/VIe Function Module Availability In StockIS230TBAI1CG01 is a Analog Input/Output terminal board manufactured and designed by General Electric. The Analog Input/Output (TBAI) terminal board has ten analog inputs and two analog outputs. The ten analog inputs support two-wire, three-wire, four-wire, and externally powered transmitters. The analog outputs can be configured for either 0-20 mA or 0-200 mA current. Noise suppression circuitry is installed on the inputs and outputs to protect against surge and high frequency noise. TBAI has three DC-37 pin connectors for connecting to the I/O processors. A single connector is used to support simplex applications (JR1). All three connectors are compatible with TMR applications. The input signals in TMR applications are fanned to the three connectors for the R, S, and T controls. TMR outputs combine the currents of the three connected output drivers and use a measuring shunt to calculate the total current. The total current signal is then presented by TBAI to the I/O processors for regulation to the commanded setpoint. Installation Connect the input and output wires to the terminal board's two I/O terminal blocks. Each block is held together with two screws and has 24 terminals that accept wires up to #12 AWG. Each terminal block has an attachment point for a shield terminal. TBAI supports the following analog I/O types: Two-wire transmitter, analog input Three-wire transmitter, analog input Four-wire transmitter, analog input Analog input, transmitter powered externally Analog input, 5 V and 10 V dc voltages 0-20 mA analog output 0-200 mA analog output IS230TBAI1CG01 Operation All transducers are powered by a 24 V dc power supply provided by TBAI. Using jumpers (J#A and J#B), the inputs can be configured as current or voltage inputs. One of the two analog output circuits is 4-20 mA, while the other can be set to 4-20 mA or 0-200 mA. All transducers are powered by a 24 V dc power supply provided by TBAI. Using jumpers (J#A and J#B), the inputs can be configured as current or voltage inputs. One of the two analog output circuits is 4-20 mA, while the other can be set to 4-20 mA or 0-200 mA. Each 24 V dc power output is rated to deliver 21 mA continuously and is protected from short circuit operation. Transmitters/transducers can be powered by the control system's 24 V dc source or can be powered independently. The type of current output is selected by jumper JO. Diagnostics are performed on each output, and a suicide relay in the I/O controller disconnects the corresponding output if a fault cannot be cleared by a processor command. Analog inputs in a TMR system are distributed to the three I/O packs. The transducers receive 24 V dc power from all three controllers and are diode shared on TBAI. Currents from all three controllers are fed into each analog current output. A series resistor is used to measure the actual output current, which feeds a voltage back to each I/O controller. The output is the voted middle (median) value of the three currents. IS230TBAI1CG01 Diagnostics The following diagnostic tests are performed on the terminal board: The voltage drop across a series resistor on the board indicates the output current. If either of the two outputs becomes unhealthy, the I/O processor generates a diagnostic alarm (fault). Each cable connector on the terminal board has its own ID device, which the I/O controller queries. The ID device is a read-only chip that is programmed with the terminal board serial number, board type, revision number, and JR, JS, and JT connector location. When the I/O controller reads this chip and finds a mismatch, a hardware incompatibility fault is generated. Configuration Jumpers are used to configure the terminal board. Refer to the installation diagram for the location of these jumpers. The available jumpers are as follows: Jumpers J1A through J8A allow you to select either current or voltage input. Jumpers J1B through J8B determine whether or not the return is connected to common. Jumpers J9A and J10A select an input current of 1 mA or 20 mA. Jumpers J9B and J10B determine whether or not the return is connected to common. Jumper J0 selects either 20 mA or 200 mA for output 1.GE CIRCUIT BOARD

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|