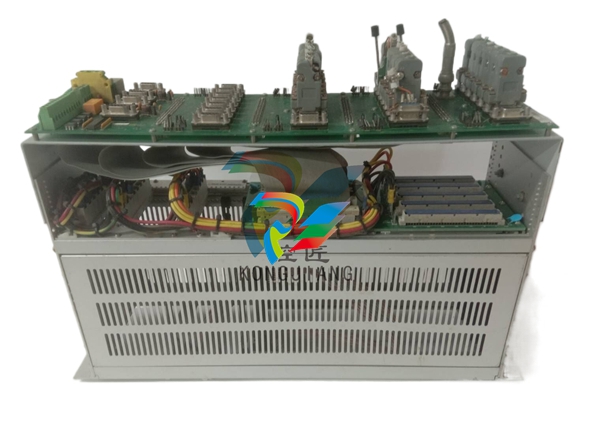

Part Number IS200SCLSH1A Manufacturer General Electric Country of Manufacture As Per GE Manufacturing Policy Series Mark VI/VIe Function Module Availability In StockIS200SCLSH1A is a core analog terminal board designed and developed by GE. It is a part of Mark VIe control system. The Core Analog Terminal Board serves as the interface for routing terminals and signals to the BCLA board. It accommodates various inputs, including eight thermocouple inputs, four analog inputs, and eight RTD inputs. Each of the four 4-20 mA inputs has its dedicated 24 V dc power source. The output channel delivers a single 4-20 mA simplex output signal. To facilitate field wire connections, there are a total of seventy-two pluggable Euro-style box-type terminal blocks. These terminal blocks are organized into three sets of 24 terminals each, providing convenient access points for field wiring. INSTALLATION The installation process involves more than just the connection of terminal blocks. Included in the setup is an I/O cable shield terminal, specifically designed for this purpose. It's crucial to note that certain terminal points, namely 23, 24, 43, 44, 45, 46, 47, and 48, are intentionally left unconnected as part of the installation configuration. Regarding the field device input/output (I/O), connectivity occurs through 72 Euro-style box terminals positioned along the edge for one section and an additional 48 Euro-style box terminals situated on the SCLT edge for another section. These terminals facilitate the interface and interaction between the field devices and the system, enabling seamless data transmission and operation. OPERATION During the operational phase, the primary function of the terminal board is to oversee and manage the customer terminals while effectively directing signals to the BCLA (Board for Control and Analog processing). This process ensures the efficient transmission of signals and data between various components within the system. To facilitate connectivity, SCLS (presumably a system or manufacturer) offers J2 connectors equipped with 68 pins, specifically designed for the terminal board cable. These connectors serve as the interface between the terminal board and its associated cables.

The terminal board, housed within the module, is responsible for the organized transmission of signals, efficiently directing them towards the connectors linked to the BCLA analog processing board. For wiring connections from field devices, the setup incorporates 72 pluggable Euro-style box terminals. These terminals are structured into three distinct sets, each comprising 24 terminals. This grouping simplifies organization and management, streamlining the process of connecting field wires to the system for data exchange and functionality. THERMOCOUPLES Thermocouples are vital sensors accepted by the PCLA (Presumably a component or system) in various types, including E, J, K, S, and T, along with mV inputs. SCLS (the system or entity) facilitates the termination of simplex inputs originating from the field, catering to eight thermocouple inputs configured in a simplex manner. To integrate these thermocouples seamlessly, a direct connection of the thermocouple wires to the thermocouple I/O terminal blocks is required. These terminal blocks, designed for easy removal, are affixed to the terminal board using two screws, ensuring a secure and reliable connection. The eight thermocouple inputs can be configured as either grounded or ungrounded, providing flexibility based on system requirements. These inputs maintain a maximum two-way cable resistance of 450 ohms and can be positioned up to 300 meters (984 feet) away from the turbine control cabinet, allowing for extended placement while retaining functionality. The SCLS terminal boards encompass a cold junction reference device, essential for accurate thermocouple measurements, along with provisions for high-frequency noise suppression. Additionally, the crucial tasks of analog-to-digital conversion and linearization, tailored for individual thermocouple types, are efficiently managed by the I/O processor. This processing capability ensures precise and reliable interpretation of the thermocouple inputs, optimizing their functionality within the system. CHARACTERISTICS Size: 5.625 inch x 9.1 inch Temperature: -30 to 65 degrees Celcius Technology: Surface mount FEATURES Number of Channels: The system boasts an impressive array of input and output channels, comprising 8 Thermocouples, 4 Analog inputs, 8 RTDs, and 1 Current Output. This diversity of channels allows for comprehensive data monitoring and control capabilities. Supply Input (P28): Power is efficiently supplied to the system through the P28 connector, with a seamless connection to P1 on the PCLA module. This ensures a reliable and robust power supply for uninterrupted operation. Interface: The system is equipped with advanced interface capabilities, fostering seamless communication and integration with both the SCLT and BCLA modules. This interconnectedness enhances the system's versatility and functionality. Fault Detection: A vigilant fault detection mechanism is integrated into the system, capable of identifying incorrect ID chips. This feature ensures the integrity and reliability of data processing by flagging any discrepancies in chip identification. Thermocouple Channels (8): Eight dedicated channels are specifically designed to accommodate a variety of thermocouple types, including E, J, K, S, T thermocouples, and mV inputs. This extensive compatibility broadens the system's applicability across diverse industrial scenarios. Span: The system's span covers an impressive range, spanning from -16.0 mV to +63.0 mV. This wide span allows for the precise measurement and control of a broad spectrum of analog signals. Cold Junction Compensation: The system incorporates a sophisticated cold junction compensation mechanism. It accurately measures the reference junction temperature, ensuring precision in temperature measurements and compensation. Cold Junction Temperature Accuracy: The cold junction temperature accuracy is an exceptional 1.1 degrees Celsius. This level of accuracy ensures that temperature measurements are incredibly reliable and align with stringent industry standards. ANALOG INPUTS Number of Channels: The analog input module is equipped with four distinct channels, enabling the system to monitor and process data from multiple sources simultaneously. Input Span for Transmitters: These channels are designed to accommodate input spans ranging from 1 to 5 V dc. This input range is achieved across a precision resistor, typically set at 250 ohm, ensuring accurate and reliable signal measurement. Maximum Lead Resistance: The system allows for a maximum lead resistance of 15 ohm. This encompasses two-way cable resistance, permitting cable lengths of up to 300 meters (approximately 984 feet). This extended reach ensures flexibility in system configuration and component placement. Outputs: Each channel within the analog input module produces 24 V dc outputs, each rated at 21 mA. These robust outputs are well-suited for a variety of applications, offering both power and versatility in signal transmission and control. ANALOG OUTPUTS Number of Channels: In contrast to the multiple input channels, the analog output module features a single channel. This channel is designed to provide a controlled output signal to external devices or systems. Load on Output Currents: The analog output channel is capable of accommodating a load of up to 800 ohm burden for its 4-20 mA output signal. This capability allows for a wide range of connected devices and ensures compatibility with various load requirements. Compliance Voltage: The compliance voltage for the analog output channel is set at 18 V dc. This voltage level ensures that the output signal can adequately drive connected devices or circuits while maintaining signal integrity and stability.POWER DISTRIBUTION MODULE

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|