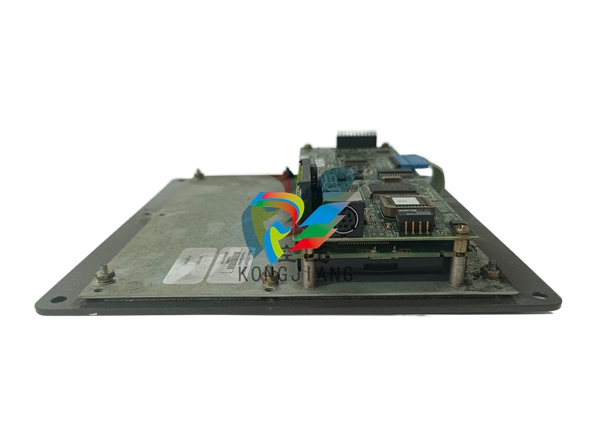

Part Number IC3600TFCV1 Manufacturer General Electric Country of Manufacture As Per GE Manufacturing Policy Series Mark VI/VIe Function Module Availability In StockIC3600TFCV1 is a Firing Circuit developed by GE, part of the Mark I and II control systems. These systems manage the turbine's operational performance, ensuring it operates efficiently and effectively according to its intended application. The primary focus of the system is on governing the performance of the turbine. Speed/Load Control Features Speed/Load Control System: This component is crucial for gas turbines, managing the speed of the turbine output shaft to ensure optimal performance and stability. The system can operate in various modes based on application requirements, primarily focusing on speed control and load management. Isochronous Control Mode: In this mode, the system maintains the turbine speed precisely at the setpoint, regardless of load variations. The turbines speed remains constant even if the load changes. Isochronous control is typically used in mechanical drive applications where maintaining a consistent speed is crucial, and the turbine is not synchronized with a larger system. Droop Control: This mode allows the turbine speed to decrease as the load increases, providing a proportional response between speed and load. Droop control is used in generator drive applications where the turbine operates in synchronization with a larger power system. The turbine's speed control function helps manage the load by adjusting according to system demands. This mode is active except when the turbine reaches its maximum allowable exhaust temperature. Generator Drive Systems: In these systems, the speed control function is continuously active. The setpoint determines the turbine芒s load, and changes in the setpoint influence the turbines loading and unloading rates. Control inputs can come from local switches on the turbine or generator panel, or from remote raise/lower switches. A load limiter can be used to manage the maximum load based on signals proportional to the generator load, offering three load settings: spinning reserve, an intermediate preselected load, and maximum load. Mechanical Drive Applications: In these applications, the turbineS output is directly linked to the speed of the driven equipment. The turbine speed is not synchronized with any external system, making isochronous control the preferred method for ensuring consistent speed regulation. Setpoint Controller: This controller adjusts the turbine speed or load based on input commands. The setpoint can be modified using either local switches on the turbine or generator panel or remote raise/lower switches. Load Limiter: The load limiter regulates the maximum allowable load based on predefined settings and signals related to the generator load. It provides flexibility in managing load limits and ensures that the turbine operates within safe and efficient parameters. Operational Adjustment: The system dynamically adjusts the turbine speed according to the chosen control mode (isochronous or droop) and input commands, ensuring efficient operation and effective response to changes in load.FIRING CIRCUIT

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|