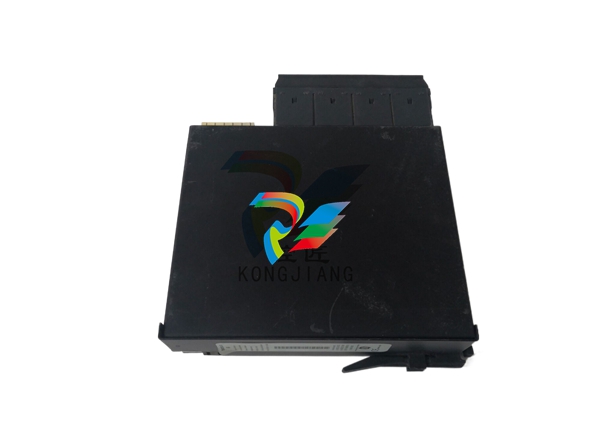

Part Number IS200AEPAH1A Manufacturer General Electric Country of Manufacture As Per GE Manufacturing Policy Series Mark VI/VIe Function Module Availability In StockThe IS200AEPAH1A is an Optional Auxiliary Board developed by GE, designed as part of the Drive Control system. This board features an auxiliary component that attaches using screws inserted into standoffs. It communicates with the main board through two male pin connectors located in the upper left corner. The board includes several integrated circuits, two female phone plugs, a three-pin female connector, and two light-emitting diodes (LEDs) along the left edge, all contributing to its functionality. Features Connectors and Components: Seventeen female-pin vertical connectors are distributed along the board's edges, varying in pin counts from two to twenty. The board also has several sizable factory-made holes, some of which are plated. Integrated circuits, resistors, transistors, and capacitors are embedded within the board's architecture, enhancing its functionality and performance. Identification and Housing: Marked as HW1, a single C-shaped metal housing is positioned on the board, which may serve a specific purpose or indicate a distinct functional area within the module setup. Human Machine Interface (HMI) Features The operator interface, or Human Machine Interface (HMI), is crucial within control systems. It typically operates as a PC running the Microsoft Windows NT operating system, supporting client/server functionalities. The interface integrates components such as the CIMPLICITY graphics display system, a Control System Toolbox for maintenance, and a software interface designed for interaction with the Mark VI control system and other networked systems. The HMI provides an interactive platform for operators to monitor, control, and manage system operations efficiently. The CIMPLICITY graphics display system presents real-time graphical representations of system components, allowing intuitive visualization of processes, statuses, and alarms. With Microsoft Windows NT base, the HMI offers client/server capabilities for seamless communication and interaction with other network nodes. The Control System Toolbox aids in diagnostics, troubleshooting, and system maintenance. The software interface compatibility ensures integration with the Mark VI control system and other interconnected systems, facilitating data exchange, system control, and operational oversight. The HMI serves as the central hub for interaction with complex control systems, providing tools and visualizations that enhance system efficiency, productivity, and overall operational effectiveness. Storage Guidelines To protect the system from corrosion and degradation, proper storage measures are essential if immediate installation is not feasible. Avoid outdoor storage as packing cases do not offer adequate protection. Store in a clean, dry space free from temperature fluctuations, high humidity, and dust. Follow these storage instructions: Place the equipment under sufficient cover to keep it clean and dry, protected from precipitation and flooding. Use breathable covering materials like canvas; avoid plastic. Unpack the equipment as per the guidelines and label it appropriately. Maintain storage conditions within: Ambient temperature: -40 to 80脗掳C Dust-free and free from corrosive elements (e.g., salt spray, chemicals) Relative humidity: 5 to 95%, with measures to prevent condensation Rodent-free environment Avoid temperature variations that may lead to moisture condensation Product Attributes Analog Inputs (8): Supports eight analog inputs for measuring and monitoring signals such as voltage, current, temperature, or pressure, enabling precise data acquisition and control. Incremental Encoder Input (1): Captures position, speed, and direction information from rotary or linear encoders, essential for precise motion control and position feedback. Absolute Encoder Input (1): Allows the system to determine the exact position of rotating machinery or linear actuators with high accuracy, providing absolute position information. Analog Output (1): Provides an analog control signal to drive actuators, valves, or other devices requiring variable control, facilitating precise modulation of output parameters. Discrete Inputs (20): Interfaces with digital sensors, switches, or other binary devices to detect the presence or absence of signals, used for detecting events or triggering control actions. Discrete Output (1): Controls external devices such as relays, solenoids, or alarms, used to switch devices on or off based on system logic or conditions. Relay Outputs (8): Drives external loads or actuators requiring higher power levels, commonly used for switching power circuits and controlling motors. RS-485 Interfaces (2): Facilitates communication with peripheral devices using the RS-485 serial communication protocol, suitable for distributed control applications. Brake Control Output (1): Dedicated to controlling braking systems in motor control applications, ensuring precise control and management of braking mechanisms.CIRCUIT BOARD

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|