Part Number IS200IGDMH1B Manufacturer General Electric Country of Manufacture As Per GE Manufacturing Policy Series Mark VI/VIe Function Module Availability In StockIS200IGDMH1B is an IGBT gate driver board developed by GE. It is a part of EX2100 excitation system. The EX2100 is compatible with both static and rotating exciters such as brushless and Alterrex. The architecture communicates via Ethernet LAN (Unit Data Highway) with other GE equipment such as the GE Control System Toolbox (toolbox) for configuration, the turbine control, the LCI Static Starter, and the HMI (operator interface). The exciter receives power from either a power potential transformer connected to the generator terminals or an excitation transformer connected to an auxiliary bus.

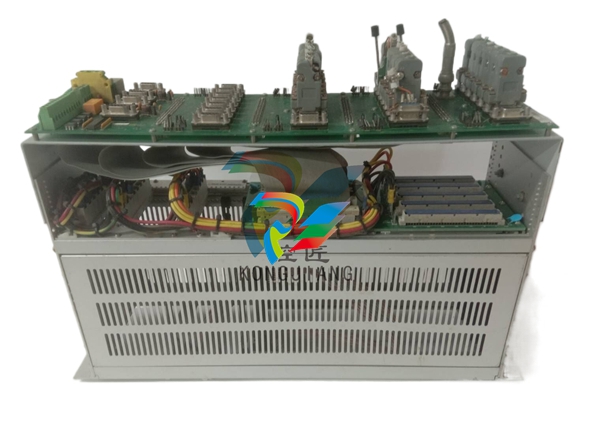

The primary feedbacks to the exciter are generator line current and stator output voltage, and the controlled output to the exciter field is dc voltage and current. IS200IGDMH1B Features It is a specialized board developed by GE with specific features and functions. Notably, this board does not have a traditional faceplate but is attached to a sub-strata made of a moldable material, which provides stability and support. The board is equipped with two vertical male two-pin connectors, labeled J1 and J2, as well as a single pin connector labeled J3. These connectors serve as connection points for various external components and wiring. In addition to the connectors, the board includes two plastic connectors and several terminal connections, allowing for secure and reliable connections within the system. An auxiliary board is soldered to the primary board, providing additional functionality and support. This auxiliary board carries several additional components, including capacitors, which contribute to the overall operation and performance of the system. The stacking of the auxiliary board with a heat sink component ensures effective heat dissipation, maintaining optimal operating temperatures and extending the lifespan of the board and its components. It is crucial to note that in the event of an IGBT (Insulated-Gate Bipolar Transistor) module failure, the board is often damaged as well and necessitates replacement. This highlights the interconnected nature of the board and its dependency on the IGBT module for proper functioning. When a failure occurs, it is necessary to replace the entire IGDM board to ensure the continued reliability and operation of the system.

The board features a unique design with no traditional faceplate, being attached to a sub-strata for stability. It incorporates vertical male connectors, plastic connectors, and terminal connections to facilitate external connections. The auxiliary board soldered to the primary board enhances functionality and carries additional components such as capacitors. The presence of a heat sink component ensures efficient heat dissipation. It is important to replace the entire board in the event of an IGBT module failure to ensure proper system operation. Operator Interface Mark VI system features a PC-based HMI (operator interface) for comprehensive system data access. Provides real-time access to events, alarms, and time tags from a centralized location. IGBT Gate Driver Board Functions as an IGBT Gate Driver board. IGBTs are key components for power control in electronic systems. Components Houses over 10 integrated circuits, transformers, resistors, capacitors, diodes, and more. Incorporates various connectors, including J1, J2, and J3. Auxiliary board soldered onto the primary board, enhancing functionality. Thermal Considerations Auxiliary board and heat sink component work together to manage heat. Reflects meticulous design for efficient thermal management. Software Overview The software utilized in the drive application program of the system is structured around functional software modules, acting as building blocks that collaborate to fulfill system requirements and ensure smooth operation. The EEPROM (Electrically Erasable Programmable Read-Only Memory) plays a significant role in storing block definitions and configuration parameters essential for the drive's operation. These parameters can be customized to suit specific system requirements and allow for efficient control and performance optimization. On the other hand, variables and dynamic data are stored in RAM (Random Access Memory), providing the flexibility to adapt to real-time changes in the system. Tune-up and diagnostic software components are integrated into the system, working transparently to the user. These components handle tasks such as optimizing drive performance and diagnosing any issues that may arise. By seamlessly integrating these software functionalities, the system can ensure optimal performance without burdening the user with complex manual adjustments or diagnostics. To facilitate operator control and interaction with the system, a door-mounted interface unit is provided. This interface unit offers a user-friendly menu-driven interface, allowing operators to navigate through various selections and perform control operations effortlessly. The menu-driven system enables operators to access and modify system settings, initiate specific functions, and monitor the drive's performance. The drive continuously monitors its performance, ensuring smooth operation and fault detection. The results of this monitoring process are displayed to the operator through animated meters, icons, and digital values on the Digital Display Interface (DDI). This real-time feedback provides operators with a clear understanding of the drive's performance and operational status, allowing for timely response and intervention when necessary. In addition to performance monitoring, the software also enables the operator to examine and reset any faults that may occur during operation. Through additional menus, operators can access detailed fault information, examine the root cause of the fault, and take appropriate corrective actions. The ability to reset faults through the software interface streamlines the troubleshooting process and helps to ensure uninterrupted operation of the system. System Hardware Overview The EX2100 hardware is housed in the following cabinets: Control Cabinet: Responsible for housing the control, communication, and input/output (I/O) boards. These boards are vital for the overall operation and control of the excitation system. The control board manages and regulates various functions, including monitoring system performance, executing control algorithms, and communicating with other system components. The communication board enables seamless communication between the excitation system and other control systems or interfaces. The I/O boards facilitate the interaction between the excitation system and external devices, allowing for the exchange of signals and data. Auxiliary Cabinet: Dedicated to field flashing and protection circuits, including de-excitation and shaft voltage suppression circuits. These circuits play crucial roles in ensuring safe and reliable operation of the excitation system. The field flashing circuit is responsible for providing the initial excitation current to the generator field winding during startup. Protection circuits, such as de-excitation and shaft voltage suppression, protect the generator and excitation system from potential damage due to abnormal conditions or voltage spikes. Power Conversion Cabinet: Houses the silicon-controlled rectifier (SCR) cells, cooling fans, DC contactors, and an AC disconnect. The SCR cells are key components responsible for converting AC power to controlled DC power. The cooling fans are integrated into the cabinet to dissipate heat generated during operation, ensuring optimal temperature levels and preventing overheating. The DC contactors facilitate the switching and control of the DC power output, allowing for proper regulation and distribution. The AC disconnect provides a means to safely disconnect the AC power supply to the system when necessary for maintenance or emergency purposes. De-Excitation Therefore the SCR conducts and dissipates the stored energy of the generator field through the field discharge device. Feedback from either conduction sensor verifies that the discharge circuit has operated successfully. If both independent firing control circuits fail to fire, the SCR is fired by the anode firing circuit when the anode to cathode voltage has exceeded the selected level. For large exciters, it is possible to connect multiple de-excitation modules together with one board configured to be the Master and the other boards configured to be Slaves. As a result, the SCR conducts and dissipates the generator field's stored energy via the field discharge device. Feedback from either conduction sensor confirms that the discharge circuit worked properly. If both independent firing control circuits fail to fire, the anode firing circuit fires the SCR when the anode to cathode voltage exceeds the selected level. Multiple de-excitation modules can be connected together for large exciters, with one board configured as the Master and the other boards configured as Slaves. Control Module The control module in the EX2100 system is designed as a VME-style rack, featuring multiple boards that are cable connected to the I/O terminal boards. This rack serves as the backbone of the control system, housing the essential components required for managing the motor and its associated processes. The control module's architecture provides a flexible and modular setup, allowing for efficient control and communication between various elements of the system. The VME-style rack is divided into three distinct and independently powered sections, each dedicated to a specific controller within the system. These controllers are referred to as M1, M2, and C controllers:IGBT GATE DRIVER

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|