DCS; Industrial control system

Product

Article

NameDescriptionContent

Argument

Current Location:

PRODUCT SHOW

Description

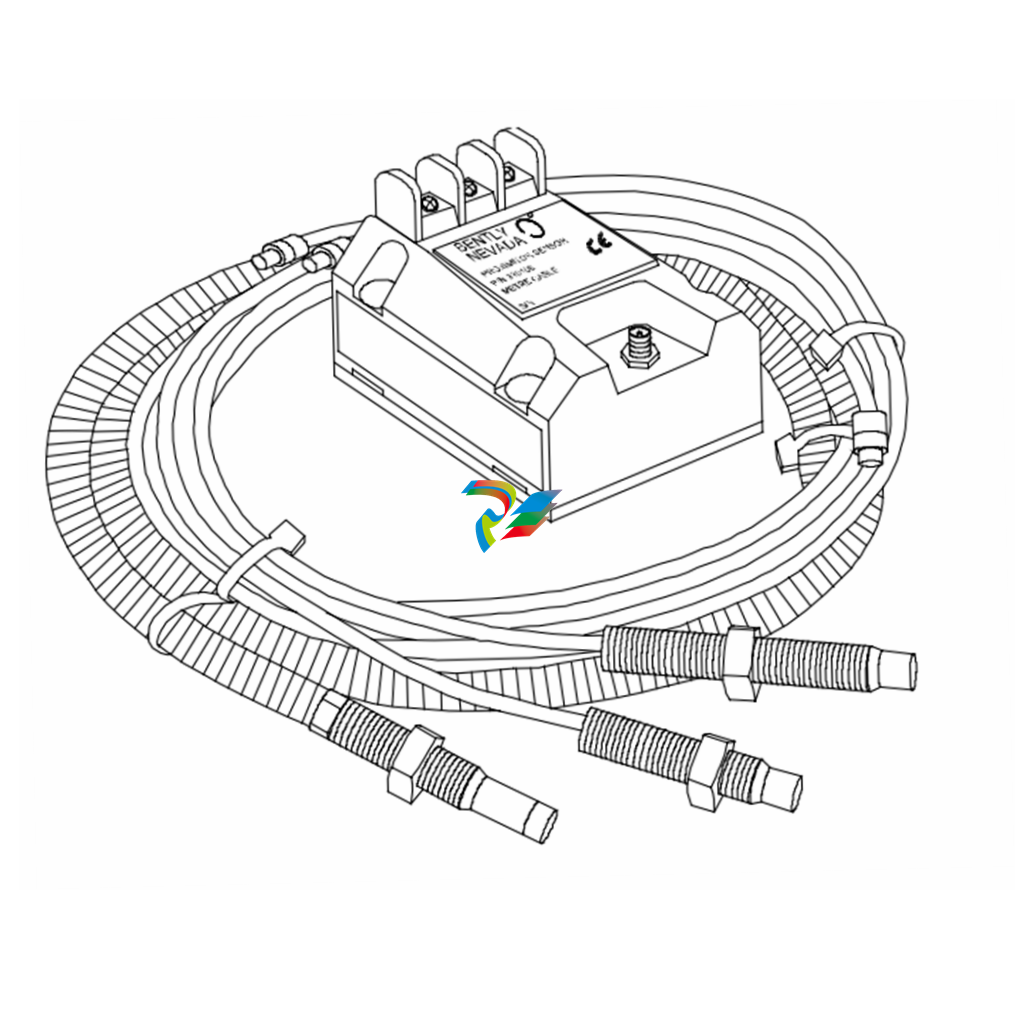

The Bently Nevada 3500/93-06-02-00 is a top-of-the-line machinery monitoring system designed for use in the power industry, petrochemical, and general automation sectors. This model is known for its advanced features, reliability, and ease of use, making it a popular choice among professionals in these industries.

Key features of the Bently Nevada 3500/93-06-02-00 include high-resolution data collection, real-time monitoring capabilities, and advanced diagnostics. The system is equipped with state-of-the-art sensors and software that can detect even the smallest changes in machinery behavior, allowing for early detection of potential issues before they escalate into costly problems.

Typical usage scenarios for the Bently Nevada 3500/93-06-02-00 include monitoring turbines, compressors, pumps, and other critical machinery in power plants, refineries, and manufacturing facilities. The system can be used to track vibration levels, temperature, and other key parameters to ensure optimal performance and prevent unexpected downtime.

One of the main advantages of the Bently Nevada 3500/93-06-02-00 is its ability to provide continuous monitoring and real-time alerts, allowing operators to take immediate action in case of any abnormalities. This helps to minimize the risk of equipment failure and production interruptions, ultimately saving time and money for businesses.

Related models within the Bently Nevada brand include:

- Bently Nevada 3500/93-08-04-01

- Bently Nevada 3500/93-03-01-00

- Bently Nevada 3500/93-03-02-01

- Bently Nevada 3500/95-04-02

- Bently Nevada 3500/93-04-04-01

- Bently Nevada 3500/93-08-03-01

- Bently Nevada 3500/93-02-02-01

- Bently Nevada 135799-01

- Bently Nevada 3500/93-05-05-00

- Bently Nevada 3500/93-02-04-00

In conclusion, the Bently Nevada 3500/93-06-02-00 is a cutting-edge machinery monitoring system with a wide range of applications in various industries. Its advanced features, reliability, and real-time monitoring capabilities make it an indispensable tool for ensuring the smooth operation of critical machinery and equipment.

Key features of the Bently Nevada 3500/93-06-02-00 include high-resolution data collection, real-time monitoring capabilities, and advanced diagnostics. The system is equipped with state-of-the-art sensors and software that can detect even the smallest changes in machinery behavior, allowing for early detection of potential issues before they escalate into costly problems.

Typical usage scenarios for the Bently Nevada 3500/93-06-02-00 include monitoring turbines, compressors, pumps, and other critical machinery in power plants, refineries, and manufacturing facilities. The system can be used to track vibration levels, temperature, and other key parameters to ensure optimal performance and prevent unexpected downtime.

One of the main advantages of the Bently Nevada 3500/93-06-02-00 is its ability to provide continuous monitoring and real-time alerts, allowing operators to take immediate action in case of any abnormalities. This helps to minimize the risk of equipment failure and production interruptions, ultimately saving time and money for businesses.

Related models within the Bently Nevada brand include:

- Bently Nevada 3500/93-08-04-01

- Bently Nevada 3500/93-03-01-00

- Bently Nevada 3500/93-03-02-01

- Bently Nevada 3500/95-04-02

- Bently Nevada 3500/93-04-04-01

- Bently Nevada 3500/93-08-03-01

- Bently Nevada 3500/93-02-02-01

- Bently Nevada 135799-01

- Bently Nevada 3500/93-05-05-00

- Bently Nevada 3500/93-02-04-00

In conclusion, the Bently Nevada 3500/93-06-02-00 is a cutting-edge machinery monitoring system with a wide range of applications in various industries. Its advanced features, reliability, and real-time monitoring capabilities make it an indispensable tool for ensuring the smooth operation of critical machinery and equipment.

Bently Nevada 3500/93-06-02-00 - Transmitter Interface Module

The Bently Nevada 3500/93-06-02-00 is a top-of-the-line machinery monitoring system designed for use in the power industry, petrochemical, and general automation sectors. This model is known for its advanced features, reliability, and ease of use, making it a popular choice among professionals in these industries.

The Bently Nevada 3500/93-06-02-00 is a top-of-the-line machinery monitoring system designed for use in the power industry, petrochemical, and general automation sectors. This model is known for its advanced features, reliability, and ease of use, making it a popular choice among professionals in these industries.Key features of the Bently Nevada 3500/93-06-02-00 include high-resolution data collection, real-time monitoring capabilities, and advanced diagnostics. The system is equipped with state-of-the-art sensors and software that can detect even the smallest changes in machinery behavior, allowing for early detection of potential issues before they escalate into costly problems.

Typical usage scenarios for the Bently Nevada 3500/93-06-02-00 include monitoring turbines, compressors, pumps, and other critical machinery in power plants, refineries, and manufacturing facilities. The system can be used to track vibration levels, temperature, and other key parameters to ensure optimal performance and prevent unexpected downtime.

One of the main advantages of the Bently Nevada 3500/93-06-02-00 is its ability to provide continuous monitoring and real-time alerts, allowing operators to take immediate action in case of any abnormalities. This helps to minimize the risk of equipment failure and production interruptions, ultimately saving time and money for businesses.

Related models within the Bently Nevada brand include:

- Bently Nevada 3500/93-08-04-01

- Bently Nevada 3500/93-03-01-00

- Bently Nevada 3500/93-03-02-01

- Bently Nevada 3500/95-04-02

- Bently Nevada 3500/93-04-04-01

- Bently Nevada 3500/93-08-03-01

- Bently Nevada 3500/93-02-02-01

- Bently Nevada 135799-01

- Bently Nevada 3500/93-05-05-00

- Bently Nevada 3500/93-02-04-00

In conclusion, the Bently Nevada 3500/93-06-02-00 is a cutting-edge machinery monitoring system with a wide range of applications in various industries. Its advanced features, reliability, and real-time monitoring capabilities make it an indispensable tool for ensuring the smooth operation of critical machinery and equipment.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Customer Reviews

Satisfaction :

5 Stars

No evaluation information