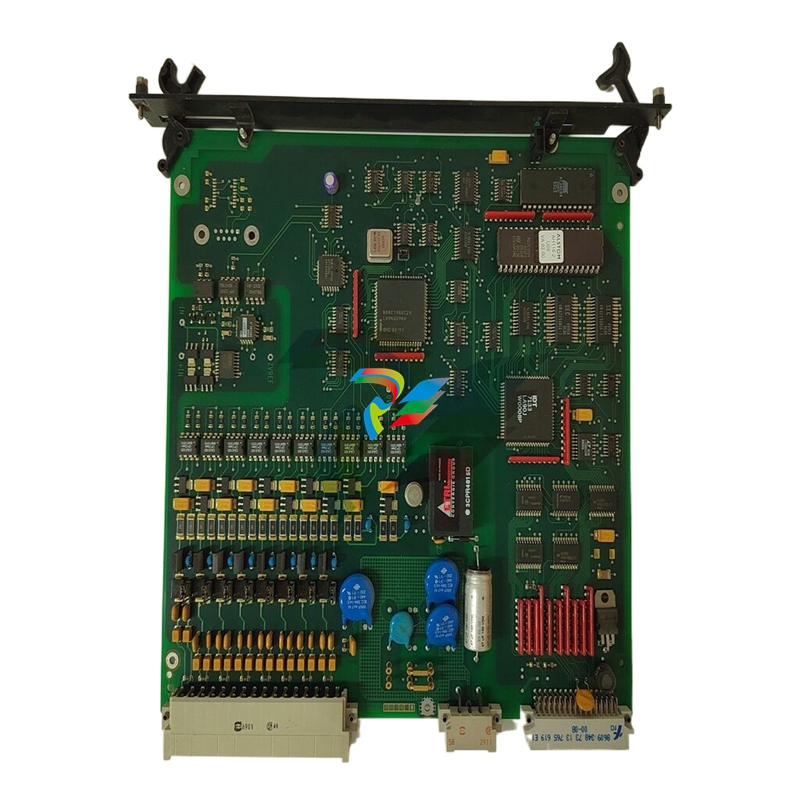

ALSTOM I4MT2U2 - / Istat programmable sensor

The ALSTOM I4MT2U2 is a high-performance automation component engineered to meet the demanding requirements of the power industry, petrochemical plants, and general automation applications. Designed with precision and durability at its core, the I4MT2U2 delivers exceptional input/output capacity and outstanding operational reliability, making it a cornerstone in complex industrial automation environments.

At the heart of the ALSTOM I4MT2U2 lies its robust input/output interface, optimized for seamless integration with a wide range of industrial control systems. The unit supports multiple I/O channels, enabling efficient data acquisition and control signal transmission with minimal latency. This ensures rapid response times critical in power generation and petrochemical processes where timing and precision are essential for safety and efficiency. Built to withstand harsh industrial conditions, the I4MT2U2 features reinforced casing and high-grade electronic components that guarantee long-term durability, even in environments exposed to temperature extremes, vibration, and electrical noise.

Performance metrics of the ALSTOM I4MT2U2 include superior data throughput and enhanced signal integrity, ensured by advanced shielding and noise reduction technologies. This model supports both analog and digital signals, offering unparalleled versatility for various automation tasks. Its modular design facilitates easy maintenance and upgrades, minimizing downtime and operational disruptions. Moreover, the I4MT2U2’s compatibility with widely used industrial protocols streamlines integration into existing setups, enhancing scalability and future-proofing investments.

In real-world applications, the ALSTOM I4MT2U2 excels in scenarios requiring precise process control and high reliability. In the power industry, it effectively manages control loops in turbine and generator control systems, optimizing performance and reducing operational risks. Petrochemical plants benefit from the I4MT2U2’s ability to handle complex chemical processing sequences, ensuring safe and efficient production cycles. General automation uses include factory automation lines and infrastructure monitoring, where its robust input/output capabilities and reliable data handling support continuous, fault-free operations.

When compared to other models within the ALSTOM automation product family, the I4MT2U2 stands out due to its balanced combination of durability, performance, and flexibility. For instance, while the ALSTOM 30MI TYPE T CLASS 2 is well-regarded for its thermal management in power applications, it lacks the extensive I/O capacity of the I4MT2U2. Similarly, the ALSTOM MVAA offers solid analog input processing but does not match the I4MT2U2’s digital signal versatility. The ALSTOM Vselc Metro 100-0-100% is tailored for metering applications but doesn’t provide the broad process control integration that the I4MT2U2 delivers.

Alongside the ALSTOM I4MT2U2, complementary ALSTOM models such as the ALSTOM PIB101C-3BD91299-B and the ALSTOM LC110 enhance system control and monitoring capabilities, while the ALSTOM GECOSTAT MC15-M2 adds robust motor control functions ideal for heavy industrial machinery. The ALSTOM Power Grinding Roll Lock Nut and ALSTOM Combustion Engineering Gasket Part # 62-278 provide critical mechanical support components often used in tandem with automation electronics to ensure system stability. For applications requiring advanced power conversion, the ALSTOM Power Conversion units integrate seamlessly, enhancing overall plant efficiency. Additionally, the ALSTOM Battery Alarm and ALSTOM External Component Box GJ229007A offer essential safety and expansion features that complement the I4MT2U2 in complex setups.

The application of the ALSTOM I4MT2U2 in the power industry, petrochemical, and general automation sectors is supported by extensive field-proven reliability and adaptability. Its ability to maintain consistent performance under varying operational stresses makes it a preferred choice for engineers and automation specialists seeking to optimize plant operations and reduce maintenance costs. Integration with existing ALSTOM automation products ensures that facilities benefit from a cohesive, scalable ecosystem of solutions designed to meet evolving industrial challenges.

In summary, the ALSTOM I4MT2U2 exemplifies robust engineering, combining high input/output capacity, durable construction, and versatile performance to meet the complex demands of power generation, petrochemical processing, and automation sectors. Its strategic compatibility with established ALSTOM models such as the ALSTOM 31v6900/10, ALSTOM CK112, ALSTOM MVAJ23R1AB0507F, and ALSTOM 1G-5556 further enhances its value proposition. Selecting the ALSTOM I4MT2U2 means investing in a reliable, high-performance automation product that supports industry-leading operational efficiency and safety standards. For those seeking superior automation solutions, the ALSTOM I4MT2U2 remains an indispensable asset within ALSTOM’s comprehensive product portfolio.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|