Key features of the Bently Nevada 580438 include advanced vibration monitoring capabilities, precise data collection, and real-time analysis. This model is equipped with state-of-the-art sensors that can detect even the slightest changes in vibration levels, allowing for early detection of potential issues before they escalate into costly failures. The 580438 also offers customizable alarm settings, remote monitoring options, and easy integration with existing automation systems.

Typical usage scenarios for the Bently Nevada 580438 include monitoring turbines, compressors, pumps, and other rotating equipment in power plants, refineries, and industrial facilities. This model is ideal for detecting abnormalities in machinery operation, such as unbalance, misalignment, bearing defects, and mechanical looseness. By continuously monitoring vibration levels, the 580438 helps to prevent unexpected downtime, increase equipment lifespan, and improve overall operational efficiency.

The basic advantages of the Bently Nevada 580438 include:

1. Enhanced equipment reliability: By providing real-time vibration data, this model helps to identify potential issues before they lead to equipment failure, minimizing unplanned downtime.

2. Improved maintenance planning: The 580438 enables predictive maintenance strategies by allowing maintenance personnel to schedule repairs based on actual equipment condition rather than fixed intervals.

3. Cost savings: By reducing the risk of catastrophic failures and optimizing maintenance schedules, the 580438 helps to lower maintenance costs and increase overall productivity.

4. Easy installation and configuration: This model is designed for user-friendly setup, with intuitive controls and clear interface for quick deployment in various industrial environments.

For those interested in similar models within the Bently Nevada brand, the following related models are available:

1. Bently Nevada 125800-02

2. Bently Nevada 3500/25-01-01-00

3. Bently Nevada 3500/22-01-01

4. Bently Nevada 3500/45-08

5. Bently Nevada 144403-01

6. Bently Nevada 126615-01

7. Bently Nevada 149716-01

8. Bently Nevada 133450-01

9. Bently Nevada 3500/42-07-01

10. Bently Nevada 162291-01

Overall, the Bently Nevada 580438 is a reliable and efficient solution for monitoring critical machinery in various industrial settings, offering advanced features, easy integration, and superior performance for ensuring equipment reliability and operational safety.

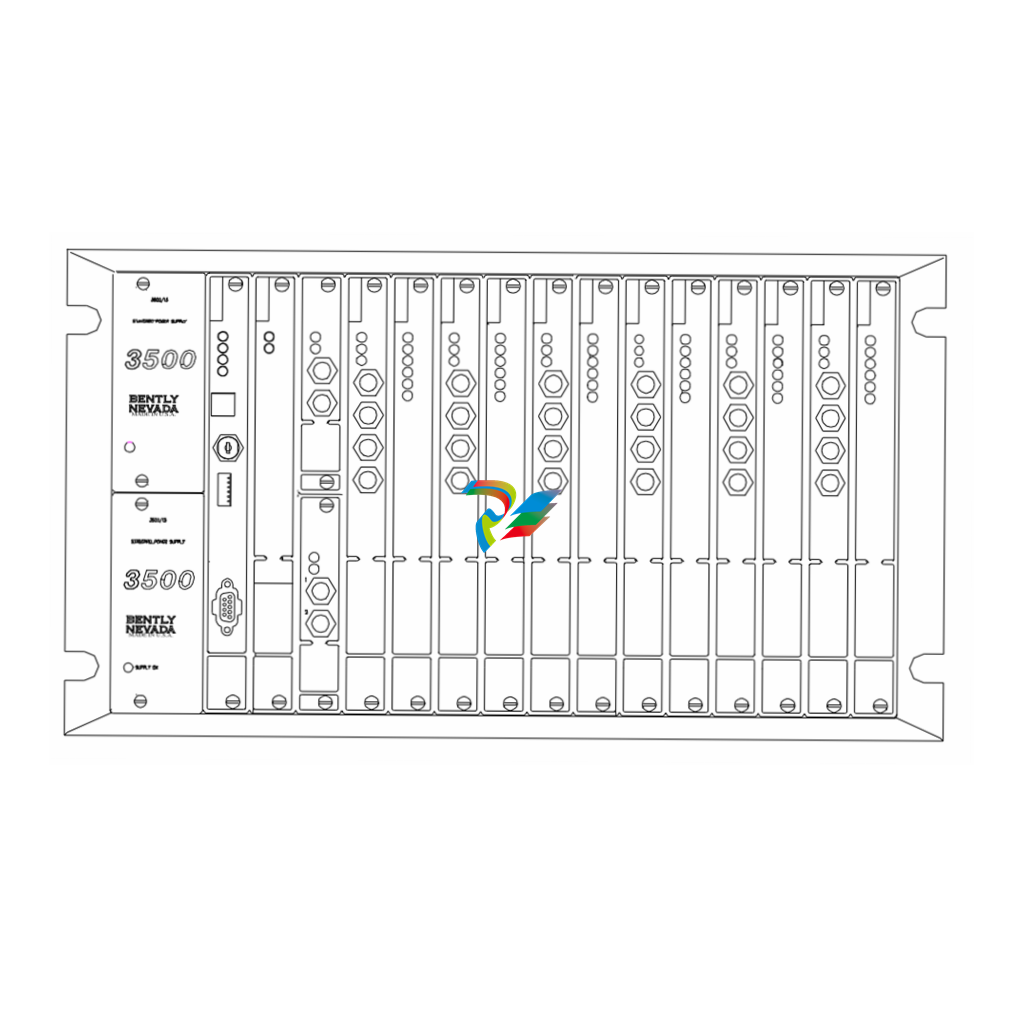

Bently Nevada 580438 - Cable Assembly

Bently Nevada 580438 - Cable Assembly

Introducing the Bently Nevada 580438, a versatile and reliable instrument designed for a variety of industries such as power, petrochemical, and general automation. This model is part of the renowned Bently Nevada product line known for its high-quality and innovative solutions for monitoring and protecting critical machinery. Key features of the Bently Nevada 580438 include advanced vibration monitoring capabilities, precise data collection, and real-time analysis. This model is equipped with state-of-the-art sensors that can detect even the slightest changes in vibration levels, allowing for early detection of potential issues before they escalate into costly failures. The 580438 also offers customizable alarm settings, remote monitoring options, and easy integration with existing automation systems. Typical usage scenarios for the Bently Nevada 580438 include monitoring turbines, compressors, pumps, and other rotating equipment in power plants, refineries, and industrial facilities. This model is ideal for detecting abnormalities in machinery operation, such as unbalance, misalignment, bearing defects, and mechanical looseness. By continuously monitoring vibration levels, the 580438 helps to prevent unexpected downtime, increase equipment lifespan, and improve overall operational efficiency. The basic advantages of the Bently Nevada 580438 include: 1. Enhanced equipment reliability: By providing real-time vibration data, this model helps to identify potential issues before they lead to equipment failure, minimizing unplanned downtime. 2. Improved maintenance planning: The 580438 enables predictive maintenance strategies by allowing maintenance personnel to schedule repairs based on actual equipment condition rather than fixed intervals. 3. Cost savings: By reducing the risk of catastrophic failures and optimizing maintenance schedules, the 580438 helps to lower maintenance costs and increase overall productivity. 4. Easy installation and configuration: This model is designed for user-friendly setup, with intuitive controls and clear interface for quick deployment in various industrial environments. For those interested in similar models within the Bently Nevada brand, the following related models are available: 1. Bently Nevada 125800-02 2. Bently Nevada 3500/25-01-01-00 3. Bently Nevada 3500/22-01-01 4. Bently Nevada 3500/45-08 5. Bently Nevada 144403-01 6. Bently Nevada 126615-01 7. Bently Nevada 149716-01 8. Bently Nevada 133450-01 9. Bently Nevada 3500/42-07-01 10. Bently Nevada 162291-01 Overall, the Bently Nevada 580438 is a reliable and efficient solution for monitoring critical machinery in various industrial settings, offering advanced features, easy integration, and superior performance for ensuring equipment reliability and operational safety.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|