ALSTOM 01601-162-00 - Washer 0.338 ID lock new

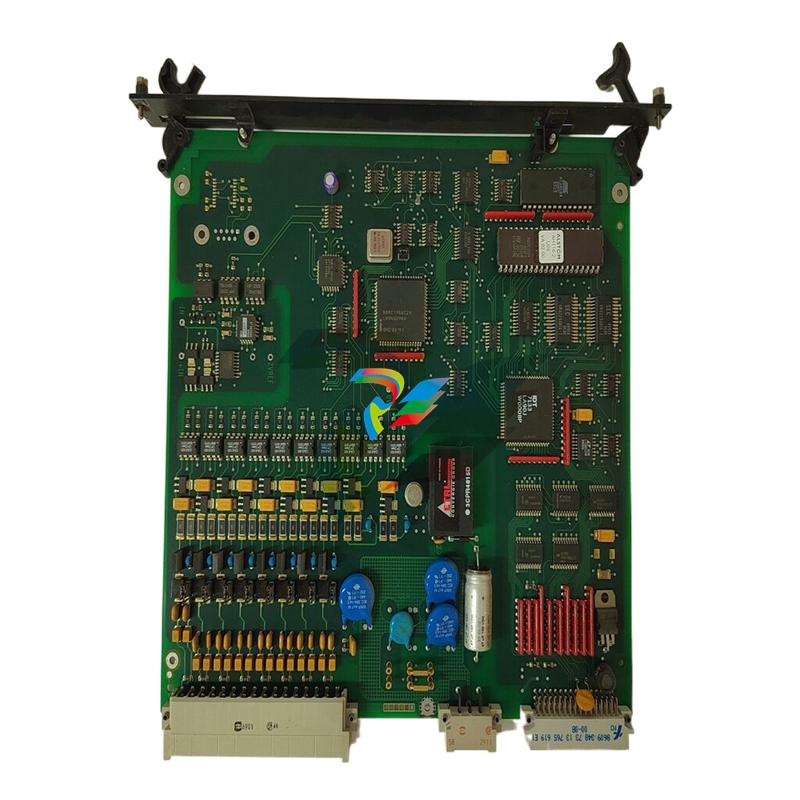

The ALSTOM 01601-162-00 stands out as a pivotal component within ALSTOM’s range of automation products, engineered specifically to meet the rigorous demands of the power industry, petrochemical plants, and general automation environments. This model is designed with precision to deliver exceptional input/output capacity, robust durability, and superior performance metrics, making it an indispensable asset for sectors requiring reliable and efficient operational control.

At its core, the ALSTOM 01601-162-00 offers a highly optimized input/output interface capable of seamless integration with diverse control systems. The unit supports a broad spectrum of analog and digital signals, allowing for flexible configuration tailored to complex industrial processes. Its input capacity is calibrated to handle high-frequency data acquisition without latency, ensuring real-time monitoring and control. Output performance is equally impressive, with rapid switching capabilities and stable signal transmission, crucial for maintaining system integrity in demanding environments.

Durability is a hallmark of the ALSTOM 01601-162-00. The device is constructed with industrial-grade materials that resist corrosion, vibration, and thermal stress, ensuring longevity even in the harshest operational conditions such as those found in petrochemical refineries and power plants. Its IP rating provides protection against dust and moisture ingress, while internal components are engineered to withstand electrical noise and fluctuations common in heavy industry. These features collectively reduce downtime and maintenance costs, enhancing overall plant efficiency.

In terms of performance metrics, the ALSTOM 01601-162-00 excels in precision and reliability. It boasts rapid response times with minimal signal distortion, ensuring accurate process control. The design incorporates advanced diagnostic capabilities, allowing operators to preemptively identify potential faults before they impact operations. This predictive maintenance feature is particularly beneficial in automation scenarios where uninterrupted functionality is critical.

Real-world applications of the ALSTOM 01601-162-00 highlight its versatility and robustness. In the power industry, it is extensively used for turbine control systems, where precise regulation of input signals affects the efficiency and safety of electricity generation. In petrochemical plants, it manages complex chemical processing units, controlling valves, pumps, and safety interlocks with high accuracy. The unit also adapts well to general automation systems, providing reliable control in manufacturing lines, packaging systems, and material handling setups, where consistent input/output performance is vital.

When compared to other ALSTOM models, the 01601-162-00 offers unique advantages in both adaptability and resilience. Unlike the ALSTOM MVAJ105JA1002A, which focuses primarily on high-voltage applications, the 01601-162-00 provides broader input/output compatibility, making it suitable for integrated automation systems. Compared with the ALSTOM SCN804 and ALSTOM scn804 d models, the 01601-162-00 delivers enhanced diagnostic features and improved environmental resistance. In contrast to the ALSTOM PIB101C-3BD91299-B and ALSTOM PIB 100G - PIB 101C series, which are more specialized for signal processing, the 01601-162-00 balances processing power with ruggedness, enabling deployment in more diverse industrial scenarios.

Alongside the ALSTOM 01601-162-00, we also offer complementary models such as the ALSTOM NBS-2 for advanced network-based control, the ALSTOM RP3-77-9783 for relay protection applications, and the ALSTOM MVAXM31D1CE3005A which excels in motor control automation. For specialized milling and material handling, the ALSTOM Bowl Mill and ALSTOM Fan Wheel Shaft provide mechanical support components that integrate well with the 01601-162-00’s control capabilities. Additionally, the ALSTOM GEM80 and ALSTOM Microverter D 3.4/500 models assist in energy conversion and drive automation, complementing the 01601-162-00’s role in system-wide process control.

The application of 01601-162-00 in power industry, petrochemical, and general automation sectors is well documented and supported by ALSTOM’s commitment to innovation and quality. Its design philosophy emphasizes modularity, ease of maintenance, and scalability, ensuring that it remains an optimal choice for evolving industrial demands. This model integrates seamlessly with ALSTOM’s broader automation ecosystem, including the ALSTOM Module C1003140 and ALSTOM RTS-61, to provide a comprehensive solution for complex industrial automation challenges.

In summary, the ALSTOM 01601-162-00 is a highly capable, durable, and versatile automation product that fulfills the stringent requirements of modern industrial applications. Its superior input/output capacity, rugged construction, and advanced diagnostic features set it apart within ALSTOM’s extensive product portfolio. When combined with related models like the ALSTOM SIR4, ALSTOM 7115, and ALSTOM 723RPS, it forms the backbone of reliable and efficient automation systems that

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|