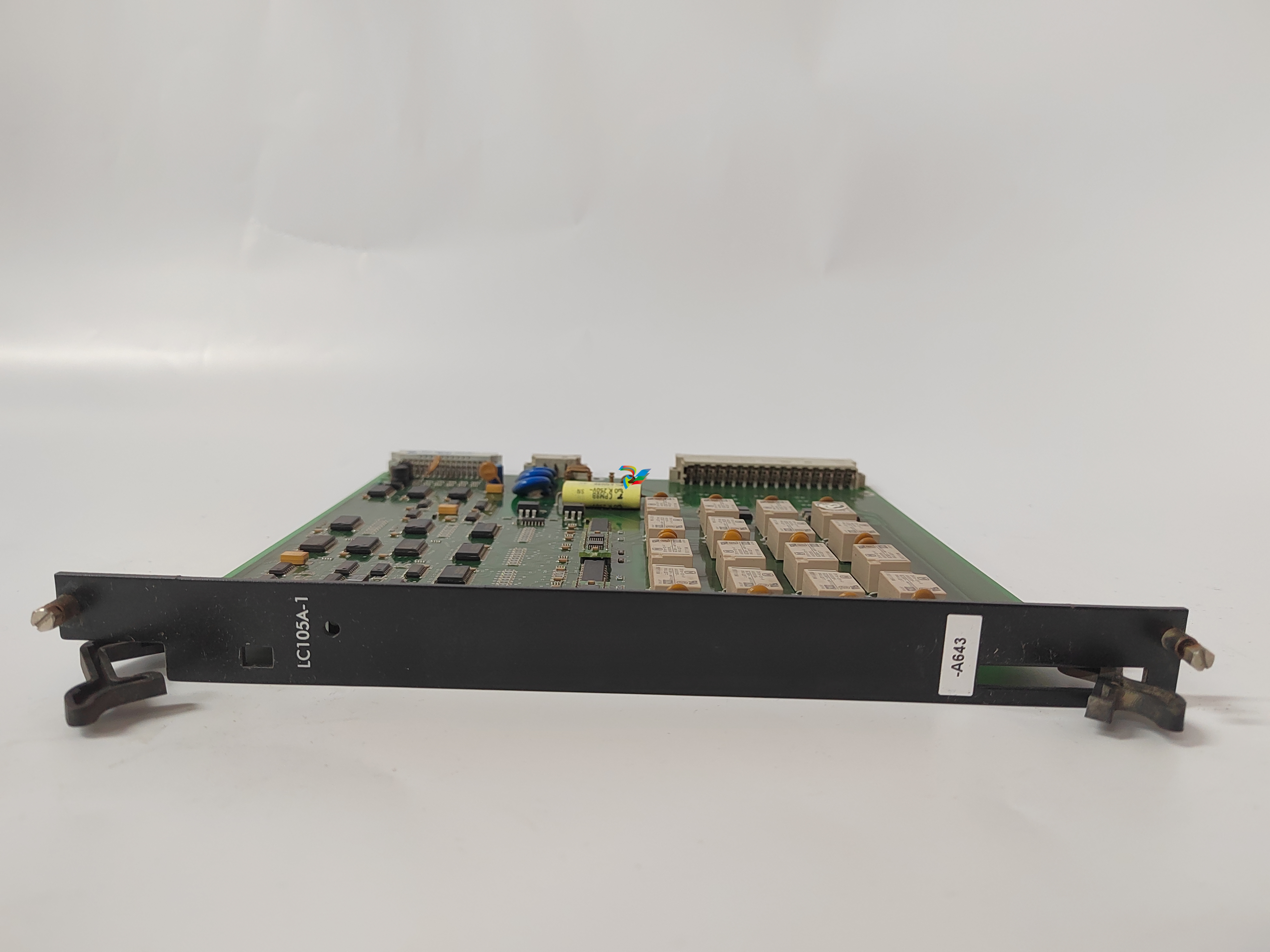

ALSTOM Blue Line (16) - Card Power Plant Control P/N 70RK01 BC

The ALSTOM Blue Line (16) stands out as a premier solution within ALSTOM’s extensive portfolio of automation products, specifically engineered to meet the rigorous demands of the power industry, petrochemical sector, and general automation applications. This model delivers exceptional input/output (I/O) capacity, robust durability, and superior performance metrics that make it indispensable in modern industrial environments.

At the heart of the ALSTOM Blue Line (16) lies its advanced processing capability, designed to handle complex automation tasks with high precision and reliability. It supports a scalable I/O configuration, allowing seamless integration with multiple sensors, actuators, and control devices. This flexibility ensures that the Blue Line (16) can efficiently manage both small-scale automation processes and large, complex systems requiring extensive data acquisition and control. The device’s throughput capacity is optimized to minimize latency, ensuring real-time responsiveness critical for safety and operational efficiency in power plants and petrochemical refineries.

Durability is another defining feature of the Blue Line (16). Built with industrial-grade components and encased in a rugged chassis, it withstands harsh environmental conditions such as extreme temperatures, vibrations, and corrosive atmospheres common in petrochemical plants and power generation facilities. This resilience minimizes downtime and maintenance costs, offering a reliable backbone for continuous operation. Performance metrics such as mean time between failures (MTBF) and operational uptime for the Blue Line (16) consistently exceed industry standards, reinforcing its reputation as a long-lasting and dependable automation product.

In real-world applications, the ALSTOM Blue Line (16) excels in managing critical functions such as load balancing in power grids, process control in chemical plants, and automated monitoring within manufacturing lines. For instance, in the power industry, it integrates effortlessly with ALSTOM’s power automation solutions, ensuring seamless control over generators, transformers, and switchgear. In petrochemical environments, its ability to handle complex process variables and maintain tight control loops directly enhances safety and product quality. Additionally, its adaptability makes it a preferred choice for general automation tasks, from assembly line control to facility energy management.

When compared to other ALSTOM models, the Blue Line (16) reveals unique advantages. Unlike the ALSTOM PIB 201A and ALSTOM PIB310, which focus primarily on specific input/output expansions, the Blue Line (16) offers a more comprehensive system integration approach with enhanced processing power and broader compatibility. Compared to the ALSTOM DINVERTER, which specializes in motor speed control, the Blue Line (16) provides a more versatile platform capable of handling diverse automation protocols and complex control algorithms. Furthermore, while the ALSTOM RTx-151 and ALSTOM SCN804 C serve niche roles in frequency detection and control interfaces, the Blue Line (16) combines those capabilities with extensive I/O management for a holistic automation control solution.

Alongside the ALSTOM Blue Line (16), we also offer complementary products such as the ALSTOM MVAAM23D12541A and ALSTOM MVAX31S1DD0754A, both of which enhance system integration and communication capabilities in large-scale automation networks. The ALSTOM MAE 96-14 and ALSTOM LFCB102 provide additional modular control and monitoring functionalities that perfectly align with Blue Line’s robust framework. For advanced user input and system interfacing, the ALSTOM JOYSTICK CONTROLLER and ALSTOM Auxiliary Relay add flexibility in manual controls and safety interlocks. Additionally, the ALSTOM Power Grinding Roll Lock Nut and ALSTOM PS 421 serve as specialized hardware components that complement the automation tasks managed by the Blue Line (16).

The application of Blue Line (16) in power industry, petrochemical, and general automation is further enhanced by its compatibility with ALSTOM’s broader ecosystem, including the ALSTOM EPIC II V4550220-0100 and ALSTOM 20x4504/10A models. These integrations allow for streamlined project deployment, simplified maintenance, and future-proof scalability. With such a comprehensive suite, the Blue Line (16) emerges not only as a standalone powerhouse but also as a key element within ALSTOM automation products designed to optimize performance, safety, and operational efficiency.

In summary, the ALSTOM Blue Line (16) is a high-performance, durable, and versatile automation product tailored for demanding industrial applications. Its superior input/output capacity, resilience in harsh environments, and advanced processing capabilities make it the ideal choice for the power industry, petrochemical sector, and general automation. When combined with other ALSTOM models like the PIB310, DINVERTER, and RTx-151, it forms a cohesive and powerful automation ecosystem capable of meeting today’s industrial challenges with precision and reliability.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|