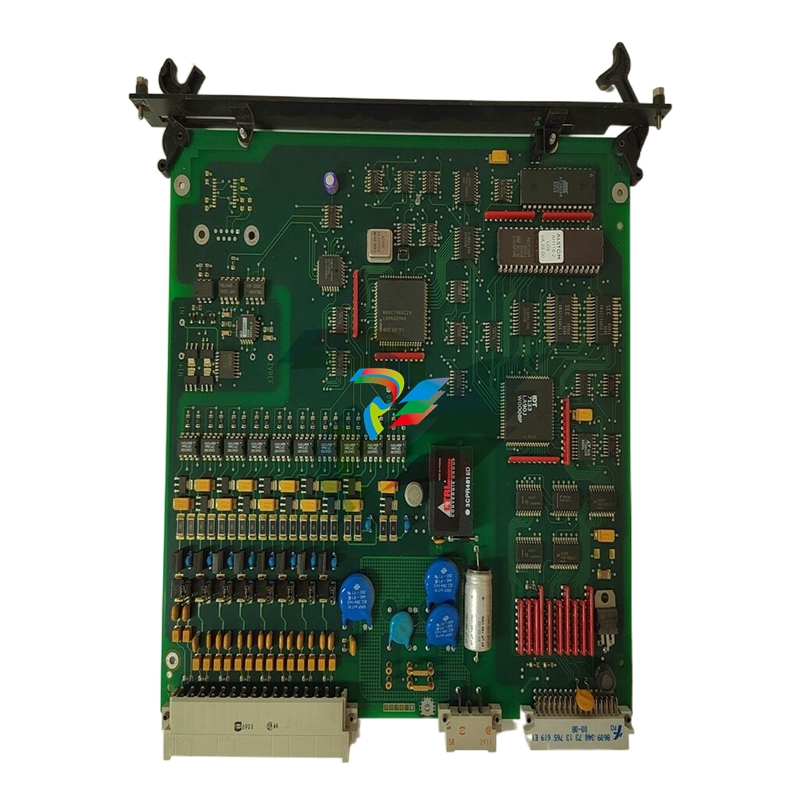

ALSTOM Pump & Motor Bracket V-VI - P/N: 66979 (New)

The ALSTOM Pump & Motor Bracket V-VI stands out as a critical component engineered to enhance the operational efficiency and reliability of pump and motor assemblies in demanding industrial environments. Specifically designed for applications across the power industry, petrochemical sectors, and general automation systems, this bracket offers a robust solution that ensures optimal alignment, vibration dampening, and load distribution between pumps and motors, thereby maximizing equipment longevity and performance.

One of the key technical features of the ALSTOM Pump & Motor Bracket V-VI is its superior durability, achieved through precision-engineered materials and advanced manufacturing techniques. The bracket supports a wide input/output capacity range, accommodating motors and pumps with power ratings typically from 5 kW up to 750 kW, depending on specific installation parameters. This versatility makes it suitable for various pump types including centrifugal, gear, and diaphragm pumps. The bracket’s design emphasizes rigidity and resistance to mechanical stress, ensuring consistent performance even in high-vibration or corrosive environments common in petrochemical plants and power generation facilities.

Performance metrics reveal that the ALSTOM Pump & Motor Bracket V-VI maintains alignment tolerances within ±0.05 mm under operational loads, a critical factor for minimizing wear and tear on coupling components. Additionally, the bracket’s architecture facilitates straightforward installation and maintenance, reducing downtime and labor costs. Its corrosion-resistant coatings and compatibility with various mounting configurations make it an ideal choice for automated systems requiring high uptime and reliability.

In real-world scenarios, the ALSTOM Pump & Motor Bracket V-VI excels when deployed in power plants where continuous pump operation is critical for cooling and circulation. In petrochemical plants, it supports pumps handling aggressive fluids, maintaining precise motor alignment to prevent seal failures and leaks. Moreover, in general automation setups, the bracket integrates seamlessly with programmable logic controllers (PLCs) and motor drives, enabling smooth operational workflows and enhanced system diagnostics.

When compared to other ALSTOM models, the Pump & Motor Bracket V-VI offers distinct advantages. For example, while the ALSTOM MPF1700G356 and ALSTOM Micon P991 focus on power conversion and control, the Pump & Motor Bracket V-VI provides the essential mechanical interface between pump and motor units. Unlike the ALSTOM Profibus DP FBK PBD MV1 65B12, which is a communication module for industrial networks, the bracket addresses the physical alignment and vibration issues that can compromise system integrity. Additionally, the ALSTOM 28x3548 and ALSTOM Drives 28x3548 models cater to drive systems, whereas the Pump & Motor Bracket V-VI ensures the foundational mechanical stability those drives require for optimal performance.

Alongside the ALSTOM Pump & Motor Bracket V-VI, ALSTOM also offers complementary products such as the ALSTOM Power MP-7848 for motor protection, the ALSTOM MVS3000-4001 for automation control, and the ALSTOM Dynamic Positioning Joystick Controller Series DP, which enhances precision in automated control environments. The ALSTOM ALSPA C80-35 and ALSTOM Microrec K4.1 L54E1100CZ further expand the portfolio, providing additional solutions for process control and signal acquisition in complex industrial systems. These models collectively support an integrated approach to automation, where mechanical stability from the Pump & Motor Bracket V-VI combines with advanced control and monitoring technologies to deliver superior operational outcomes.

In terms of SEO, the ALSTOM Pump & Motor Bracket V-VI is frequently sought after by engineers and procurement specialists looking for reliable ALSTOM automation products. Its proven application of Pump & Motor Bracket V-VI in the power industry, petrochemical, and general automation sectors underscores its critical role in maintaining system efficiency and safety. Whether ensuring the alignment of heavy-duty pumps in power generation or supporting motor-driven processes in chemical plants, this bracket embodies ALSTOM’s commitment to quality and performance.

In summary, the ALSTOM Pump & Motor Bracket V-VI combines mechanical precision, durability, and application versatility to meet the rigorous demands of industrial automation. It complements a broad range of ALSTOM products like the MPF1700G356, Micon P991, and Power MP-7848, forming a comprehensive solution suite that addresses both mechanical and control aspects of modern industrial systems. This makes it an indispensable component for professionals aiming to optimize pump and motor integration in power, petrochemical, and automated manufacturing environments.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|