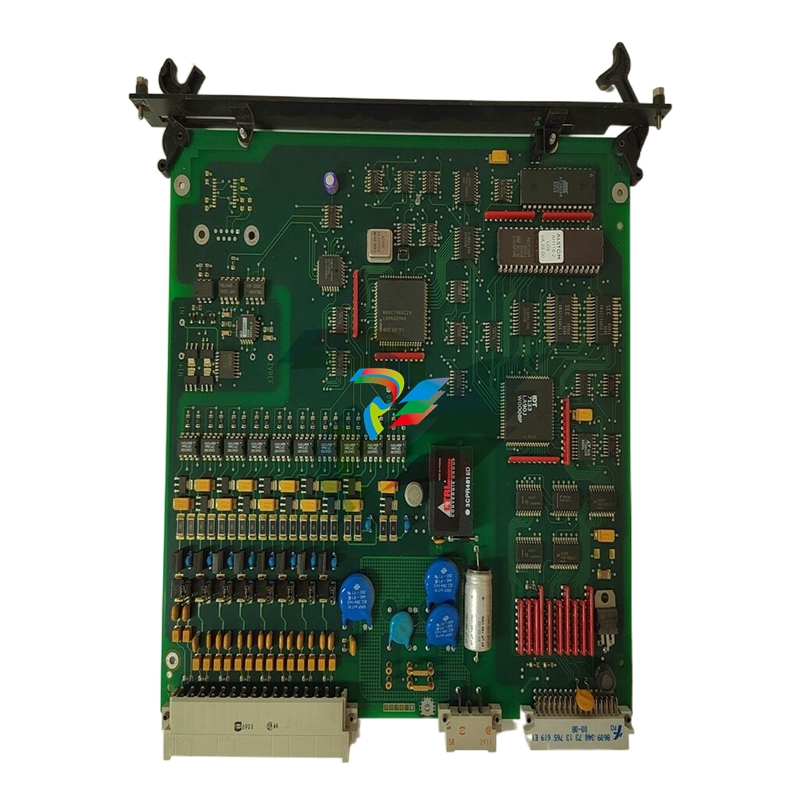

Alspa Alstom - VF 4003 B *H2R39E4*

The Alspa Alstom stands out as a premier automation product designed for the demanding requirements of the power industry, petrochemical sectors, and general automation applications. Engineered with precision, the Alspa Alstom offers robust input/output capacity, exceptional durability, and superior performance metrics, making it an indispensable component in critical industrial environments.

At the core of the Alspa Alstom’s technical features is its high-capacity input/output interface, capable of managing complex signal processing with a remarkable degree of accuracy and reliability. The device supports multiple analog and digital input channels, allowing seamless integration with existing control systems and providing real-time data acquisition essential for process optimization. With an input voltage range that accommodates both 48VAC and 60VDC at up to 10A, the Alspa Alstom ensures compatibility with a wide array of industrial power supplies. Its rugged construction enables it to withstand harsh operating conditions, including extreme temperatures, vibration, and electrical noise, which are commonplace in petrochemical plants and power generation facilities.

Performance-wise, the Alspa Alstom excels in rapid response times and minimal latency, crucial for automation tasks requiring precise timing and coordination. Its advanced relay and switching capabilities facilitate reliable operational control, reducing downtime and maintenance costs. Moreover, the unit features sophisticated diagnostic tools that enable proactive monitoring of system health, helping engineers preempt failures before they impact production.

In real-world scenarios, the Alspa Alstom is extensively used in power plants for turbine control, load management, and safety interlocks. In the petrochemical industry, it plays a vital role in monitoring pressure, temperature, and flow rates within complex processing units, ensuring safe and efficient operation. Its adaptability also makes it a favored choice in general automation settings, where it integrates with operator interfaces such as the Alspa Operator Interface and advanced microprocessor-based controls like the Alspa MICOM P145.

When compared to other Alspa models, the Alspa Alstom offers a distinctive blend of high input/output scalability and ruggedness that sets it apart. For instance, while the Alspa PS421 and Alspa PS 441 are well-regarded for their compact form factors and basic relay functions, they do not match the Alstom’s comprehensive performance capabilities or its ability to handle higher power loads. Similarly, the Alspa 8RDB44674G01 and Alspa 8RDC44667G01 models provide specialized control solutions but lack the broad application scope and diagnostic sophistication found in the Alspa Alstom.

Alongside the Alspa Alstom, we also offer complementary products such as the Alspa Converteam PIB-201A for power conversion applications, the Alspa GDS1003-4001 designed for grid synchronization tasks, and the Alspa UT129A-5 which enhances system monitoring capabilities. The Alspa 556421 and Alspa LFZR 111 models further expand automation system flexibility, while the Alspa Brown Boveri and Alspa Parvex Alstom 48VAC - 60VDC 10A units provide specialized support in power conditioning and control. For advanced relay operations, the Alspa Auxiliary Relay and Alspa Battery Alarm units ensure system reliability and safety. Finally, the Alspa MVAAM23D12541A offers enhanced interface options for integration with modern control architectures.

In conclusion, the Alspa Alstom is a versatile and reliable automation product that excels in demanding environments typical of the power industry, petrochemical plants, and general automation applications. Its advanced input/output capacity, durability, and performance metrics provide a unique advantage over other models in the Alspa range, making it an essential component for operators seeking efficiency, safety, and long-term operational stability. Whether integrated with the Alspa RTx-151 for communication or paired with the Alspa IC693BEM340 for modular control expansion, the Alspa Alstom delivers unmatched value and performance, solidifying its role as a cornerstone in modern industrial automation solutions.

By choosing Alspa automation products like the Alspa Alstom, industries benefit from cutting-edge technology tailored to the complex needs of today’s power and petrochemical sectors, driving productivity and ensuring seamless operational continuity.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|