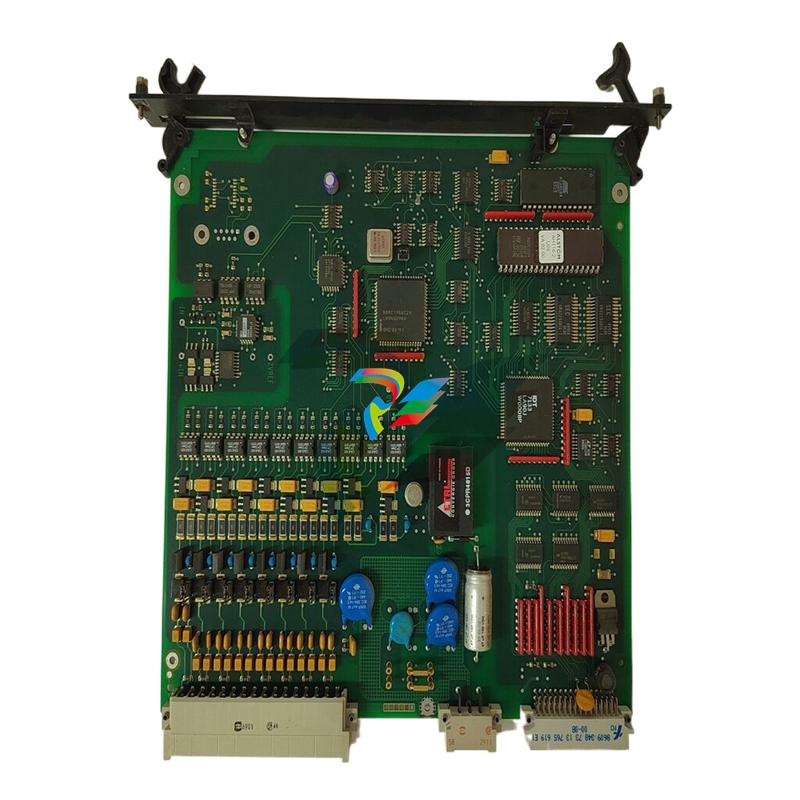

Alstom 556423 - do16

The Alstom 556423 stands out as a highly reliable and versatile component within Alstom’s extensive portfolio of automation and industrial control products. Designed specifically to meet the rigorous demands of the power industry, petrochemical plants, and general automation sectors, the Alstom 556423 offers exceptional performance, durability, and integration flexibility that make it a cornerstone in modern industrial applications.

At its core, the Alstom 556423 features robust input/output capabilities tailored for high-throughput environments. It supports multiple input channels with an impressive response time, enabling seamless real-time data acquisition and control. The output capacity is engineered to handle high electrical loads with minimal signal degradation, ensuring stable operation even under fluctuating industrial conditions. This component is built with industry-grade materials and advanced thermal management systems, enhancing its durability and operational longevity. The Alstom 556423 performs reliably across a wide temperature range and withstands harsh environmental factors commonly found in petrochemical and power generation settings.

In real-world scenarios, the Alstom 556423 excels in applications such as power plant automation where precise control and monitoring of turbines, generators, and auxiliary systems are critical. Its compatibility with existing Alstom infrastructure streamlines integration with systems like the Alstom Power Preheater and Alstom Power Grinding Roll Lock Nut, optimizing overall plant performance and reducing downtime. In petrochemical plants, the 556423’s rapid response and high reliability support critical process control tasks, including pressure regulation and safety interlocks, ensuring safe and efficient chemical processing. Furthermore, in general automation applications, the Alstom 556423 enhances system responsiveness and accuracy, making it ideal for manufacturing lines requiring precise motion control and real-time feedback.

Compared to other Alstom models such as the Alstom IM-200-230E and Alstom SCN804, the 556423 offers superior input/output density and faster processing speeds, which translates into more efficient control loops and better system responsiveness. While the Alstom MV3000 focuses on medium-voltage applications and the Alstom SKIIP2013GB172-4DK0197 caters to power electronics modules, the 556423 bridges the gap by providing comprehensive automation control with robust electrical interfacing capabilities. Unlike the Alstom MAE 00-11 and Alstom mae00-10 models, which are more specialized relay and protection devices, the 556423 integrates multiple functional roles, reducing the need for additional hardware and simplifying system architecture.

Integration with Alstom’s broader automation ecosystem is straightforward. Alongside the Alstom 556423, we also offer complementary products such as the Alstom PS 441 and Alstom PIB504 for enhanced signal processing and protection, the Alstom DW02 for diagnostic monitoring, and the Alstom MICOM series for advanced relay protection. For applications requiring precise motor control, the Alstom ALSPA GD3000E can be paired seamlessly with the 556423 to achieve optimal performance. Additionally, the Alstom VTT Definitive Time Relay and Alstom Zusatz Relay offer extended timing and switching functionalities, enhancing the control capabilities provided by the 556423. Together with these models, the Alstom 556423 forms a cohesive solution set that addresses complex automation challenges across multiple industrial sectors.

The application of 556423 in power industry, petrochemical, and general automation environments is further strengthened by its compliance with industry standards, ease of installation, and flexible configuration options. Its robust architecture ensures minimal maintenance while delivering consistent performance over long operational cycles. This makes the Alstom 556423 not just a product but a reliable partner in achieving operational excellence and safety.

In summary, the Alstom 556423 distinguishes itself through its high-capacity input/output handling, durability under extreme conditions, and broad application range. When compared to other Alstom automation products like the SCN804, IM-200-230E, and MV3000, it offers unique advantages in speed, integration, and multifunctionality. For engineers and system integrators seeking a dependable solution for power industry, petrochemical, and general automation tasks, the Alstom 556423 is an optimal choice, supported by a comprehensive ecosystem of Alstom products designed to enhance and complement its capabilities.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|