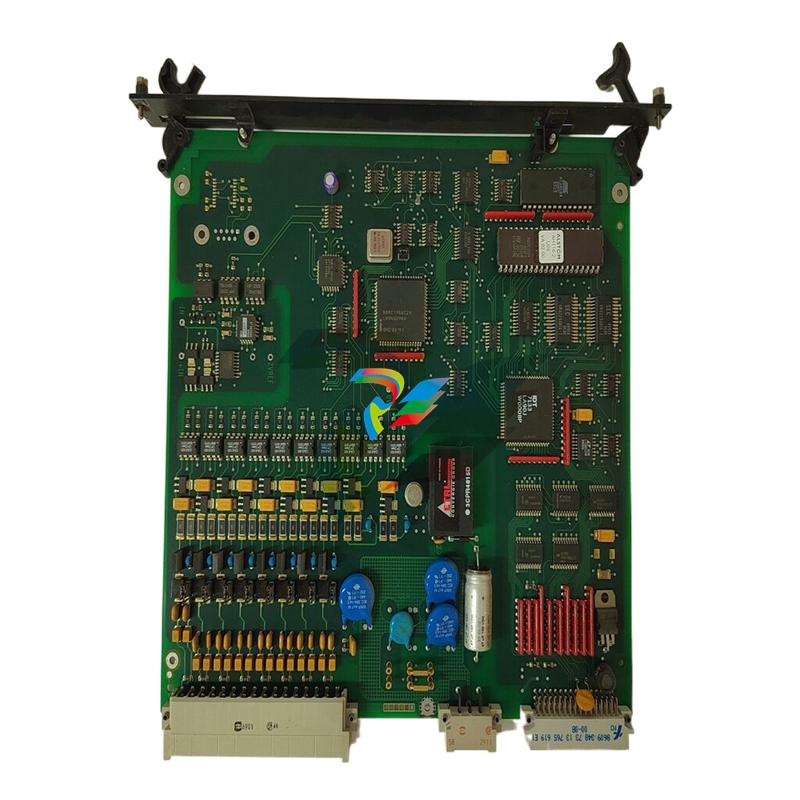

Alstom Alspa MD2000 - Control Unit

The Alstom Alspa MD2000 stands out as a pinnacle of innovation and reliability within Alstom’s extensive portfolio of automation and control solutions, specifically engineered for demanding environments such as the power industry, petrochemical sectors, and general automation applications. Designed to deliver exceptional input/output capacity combined with robust durability, the Alspa MD2000 is a versatile automation platform that meets the most stringent operational requirements.

At its core, the Alstom Alspa MD2000 boasts an advanced modular architecture capable of handling high-speed, high-volume data acquisition and control tasks with remarkable precision. Its input/output (I/O) capacity is scalable, supporting a wide range of digital and analog signals, which ensures seamless integration with complex industrial processes. Equipped with state-of-the-art processing units, the MD2000 maintains superior performance metrics, including rapid response times and real-time data processing capabilities. This efficiency translates into reduced downtime and enhanced process reliability, critical factors in power generation and petrochemical production environments where operational continuity is paramount.

Durability is another defining characteristic of the Alspa MD2000. Engineered to withstand harsh industrial conditions such as extreme temperatures, vibrations, and electrical noise, it ensures longevity and stable performance over extended service intervals. This ruggedness makes it ideally suited for continuous operation in power plants and petrochemical facilities where equipment reliability directly impacts production safety and efficiency.

In real-world applications, the Alstom Alspa MD2000 excels in managing complex automation schemes, including turbine control, boiler monitoring, and process optimization in refineries. For instance, in power plants, the MD2000 integrates seamlessly with systems like the Alstom ALSTOM MAE 99-04 and the Alstom Microverter D 3.4/500, enhancing overall plant automation and control precision. Similarly, in the petrochemical industry, it works harmoniously alongside models such as the Alstom Combustion Engineering Gasket Part # 62-278 and Alstom Fan Wheel Shaft, enabling flawless process control and equipment monitoring critical for safety and efficiency.

When compared to other Alstom automation products, the Alspa MD2000 offers unique advantages in terms of modularity and scalability. Unlike the Alstom alspa gd3000e, which is optimized for specific automation tasks, the MD2000 provides a broader I/O range and enhanced processing power, making it a more flexible choice for integrators managing diverse industrial applications. Additionally, while models like the Alstom SCN804D Medida and the Alstom MCRI01T1CD0751C focus on specialized measurement and control functions, the Alspa MD2000’s multi-functional design supports a wider spectrum of automation challenges, from basic control loops to complex distributed control systems.

Alongside the Alstom Alspa MD2000, we also offer the Alstom MT96-MPSU011 and Alstom D-984-0582 as complementary components that enhance system integration and reliability. The Alstom MT96-MPSU011 power supply unit ensures consistent energy delivery to the automation hardware, while the Alstom D-984-0582 communication module facilitates high-speed data exchange across the plant network. These components, combined with the MD2000, create a robust ecosystem for industrial automation.

Furthermore, the Alstom Alspa MD2000’s adaptability extends to interfacing with legacy and advanced equipment alike. Its compatibility with systems such as the Alstom Unit 28x3548 and Alstom Pulverizer 723RPS allows for seamless upgrades and expansions in existing installations without significant overhaul costs. This backward and forward compatibility underscores Alstom’s commitment to providing future-proof automation solutions that evolve alongside industry needs.

In summary, the Alstom Alspa MD2000 is a high-performance, durable automation product designed to meet the complex demands of the power industry, petrochemical plants, and general automation applications. Its exceptional I/O capacity, real-time processing, and rugged construction make it a reliable choice for critical industrial environments. When paired with complementary Alstom models such as the ALSTOM MAE 99-04, Microverter D 3.4/500, MT96-MPSU011, and SCN804D Medida, the Alspa MD2000 forms the backbone of comprehensive automation systems that drive efficiency, safety, and operational excellence.

For industries seeking a cutting-edge solution, the application of Alspa MD2000 in power industry, petrochemical, and general automation settings represents a strategic investment in advanced control technology. This product not only enhances process accuracy but also ensures the long-term sustainability of industrial operations, aligning with Alstom’s reputation for innovation and quality in automation products.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|