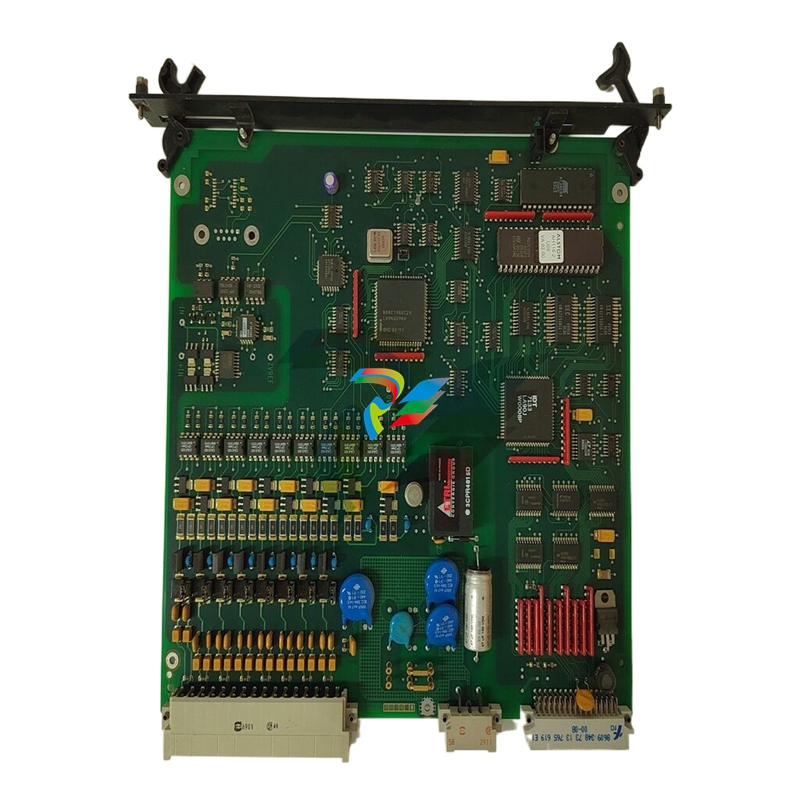

Alstom Operator Interface - Alspa Communicator P-802-117-C

The Alstom Operator Interface stands out as a critical component within Alstom’s extensive suite of automation products, specifically engineered to meet the rigorous demands of the power industry, petrochemical plants, and general automation environments. Designed with robust input/output capabilities, this Operator Interface facilitates seamless communication between human operators and complex industrial systems, ensuring precision control and real-time monitoring in mission-critical applications.

At its core, the Alstom Operator Interface features a high-resolution touch screen coupled with versatile digital and analog input/output ports, supporting up to 64 I/O channels depending on configuration. This expansive I/O capacity allows for integration with a wide range of sensors, actuators, and control devices, enabling operators to efficiently manage processes with immediate feedback. The interface supports communication protocols commonly used in industrial automation, such as Modbus, Profibus, and Ethernet/IP, ensuring compatibility with legacy and modern systems alike. Durability is another hallmark of this interface — it is housed in an industrial-grade enclosure rated to IP65 standards, providing resistance against dust, moisture, and mechanical shocks. This rugged design ensures reliable operation in harsh environments typical of petrochemical plants or power generation facilities.

Performance metrics for the Alstom Operator Interface highlight fast response times, with data refresh rates optimized to under 100 milliseconds, enabling operators to detect and respond to critical events without delay. The interface’s embedded processing unit runs on a real-time operating system, guaranteeing stable operation over extended periods and minimizing downtime. Additionally, the user interface is customizable, allowing for tailored graphical displays, alarm management, and multi-language support to suit diverse industrial settings.

In real-world applications, the Alstom Operator Interface excels in controlling turbine generators within power plants, managing safety systems in petrochemical refineries, and automating assembly lines in manufacturing plants. For instance, in a power industry setting, the interface integrates seamlessly with Alstom’s Micom p743 protection relays, providing operators with detailed fault diagnostics and control capabilities. Similarly, in petrochemical operations, it coordinates with the Alstom PRIMA control systems to maintain optimal process conditions and ensure safe plant operation. The interface also complements Alstom’s 8RDA44670G01 and 8RDB44674G01 models, which are often employed for signal conditioning and relay functions, enhancing overall system responsiveness and safety.

Compared to other Alstom models, the Operator Interface offers distinct advantages in flexibility and user engagement. While devices like the Alstom Combustion Engineering units focus primarily on combustion control and monitoring, the Operator Interface provides a more holistic platform for process visualization and interaction. Furthermore, its integration capabilities surpass those of the Alstom Carborne models, which are specialized for rail and transit applications and may lack the industrial-grade ruggedness required in petrochemical or power plant environments. When paired with Alstom’s Power Aptec Right Grip Lever Part D-90-257-64 for manual override and the Alstom JOYSTICK CONTROLLER STATION for precise manual control, the Operator Interface forms the backbone of a comprehensive human-machine interface ecosystem.

Alongside the Alstom Operator Interface, we also offer the Alstom SCN804 and SCN804D Medida models for advanced signal processing and measurement tasks. The Alstom MVAAM and Alstom Parvex Alstom 48VAC - 60VDC 10A serve as reliable power modules ensuring stable operation across all connected devices. For high-torque motor control scenarios, the Alstom DINVERTER and Alstom Microverter D 3.4/500 provide efficient variable frequency drive solutions that integrate neatly with the operator interface system. These complementary products underscore Alstom’s commitment to delivering fully integrated automation solutions tailored to demanding industrial applications.

The application of the Alstom Operator Interface in the power industry, petrochemical sector, and general automation underscores its versatility and performance excellence. By providing operators with intuitive control, real-time data visualization, and rugged reliability, it enhances operational efficiency and safety. Whether managing high-capacity generators, complex chemical process controls, or automated assembly systems, this interface ensures that critical decisions are supported by accurate, timely information.

In summary, the Alstom Operator Interface is a cornerstone of modern industrial automation, delivering a blend of robust hardware, flexible connectivity, and intuitive operation. When combined with other Alstom automation products such as the Micom p743, PRIMA, SCN804, and JOYSTICK CONTROLLER STATION, it enables comprehensive, scalable solutions that meet the evolving needs of power generation, petrochemical processing, and general automation industries worldwide.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|