Key Features:

- Real-time vibration monitoring: The 3500/15-01-02-01 continuously monitors vibrations in machinery and equipment, providing real-time data to help prevent potential failures.

- Data analysis capabilities: This model is equipped with sophisticated data analysis tools that allow users to identify patterns and trends in vibration data, enabling predictive maintenance strategies.

- Remote monitoring: The 3500/15-01-02-01 can be accessed remotely, allowing users to monitor equipment health from anywhere, at any time.

- High accuracy sensors: This model comes with high-quality sensors that provide accurate vibration measurements, ensuring reliable performance.

- Easy installation and setup: The 3500/15-01-02-01 is designed for easy installation and setup, saving time and effort during implementation.

Typical Usage Scenarios:

- Power industry: In power plants, the 3500/15-01-02-01 is used to monitor the vibration levels of turbines, generators, and other critical equipment to prevent unexpected failures and downtime.

- Petrochemical plants: In petrochemical facilities, this model helps monitor the condition of pumps, compressors, and other machinery to ensure safe and efficient operations.

- General automation: In various automation applications, the 3500/15-01-02-01 is used to monitor the health of rotating equipment, reducing maintenance costs and improving overall system reliability.

Basic Advantages:

- Early fault detection: The 3500/15-01-02-01 helps detect potential faults in machinery before they escalate into major problems, saving time and money on repairs.

- Increased equipment lifespan: By monitoring vibration levels and identifying issues early on, this model helps extend the lifespan of equipment and reduce the risk of unexpected failures.

- Improved safety: By ensuring that machinery is operating within safe vibration limits, the 3500/15-01-02-01 helps prevent accidents and injuries in industrial settings.

Related Models:

- Bently Nevada 3500/15-04-02-01

- Bently Nevada 3500/15-02-01

- Bently Nevada 3500/60

- Bently Nevada 3500/05-01-02-00-00-00

- Bently Nevada 3500/15-02-02-00

- Bently Nevada 3500/15-03-04

- Bently Nevada 3500/15-02-03-00

- Bently Nevada 3500/15-04-04-01

- Bently Nevada 3500/15-01-03-00

- Bently Nevada 3500/15-02

In conclusion, the Bently Nevada 3500/15-01-02-01 is a top-of-the-line vibration monitoring system that offers advanced features, reliable performance, and ease of use. Whether in the power industry, petrochemical plants, or general automation applications, this model is an essential tool for maintaining equipment health and ensuring smooth operations.

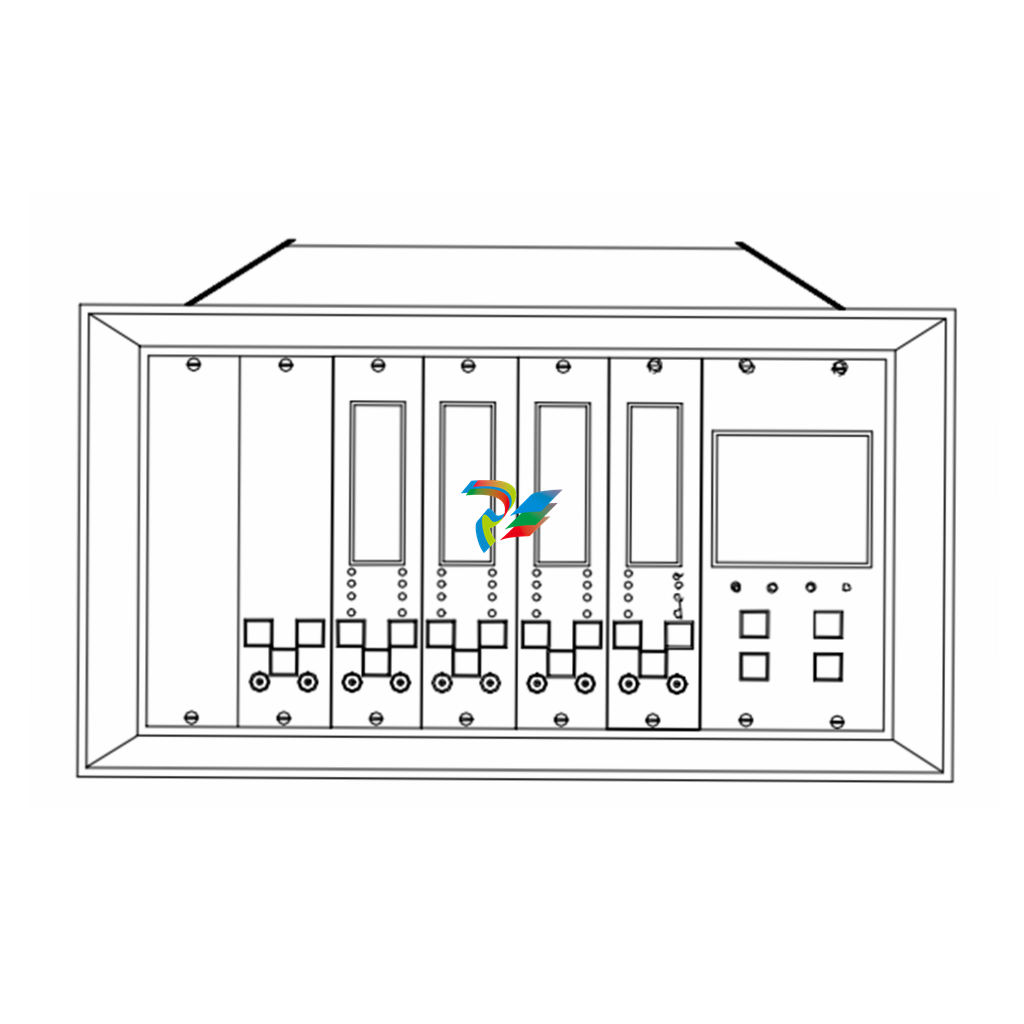

Bently Nevada 3500/15-01-02-01 - Power Supply Module, AC/DC Input

The Bently Nevada 3500/15-01-02-01 is a highly reliable and versatile vibration monitoring system designed for use in the power industry, petrochemical plants, and general automation applications. With its advanced features and robust construction, this model is a popular choice among professionals in these industries.

Key Features:

- Real-time vibration monitoring: The 3500/15-01-02-01 continuously monitors vibrations in machinery and equipment, providing real-time data to help prevent potential failures.

- Data analysis capabilities: This model is equipped with sophisticated data analysis tools that allow users to identify patterns and trends in vibration data, enabling predictive maintenance strategies.

- Remote monitoring: The 3500/15-01-02-01 can be accessed remotely, allowing users to monitor equipment health from anywhere, at any time.

- High accuracy sensors: This model comes with high-quality sensors that provide accurate vibration measurements, ensuring reliable performance.

- Easy installation and setup: The 3500/15-01-02-01 is designed for easy installation and setup, saving time and effort during implementation.

Typical Usage Scenarios:

- Power industry: In power plants, the 3500/15-01-02-01 is used to monitor the vibration levels of turbines, generators, and other critical equipment to prevent unexpected failures and downtime.

- Petrochemical plants: In petrochemical facilities, this model helps monitor the condition of pumps, compressors, and other machinery to ensure safe and efficient operations.

- General automation: In various automation applications, the 3500/15-01-02-01 is used to monitor the health of rotating equipment, reducing maintenance costs and improving overall system reliability.

Basic Advantages:

- Early fault detection: The 3500/15-01-02-01 helps detect potential faults in machinery before they escalate into major problems, saving time and money on repairs.

- Increased equipment lifespan: By monitoring vibration levels and identifying issues early on, this model helps extend the lifespan of equipment and reduce the risk of unexpected failures.

- Improved safety: By ensuring that machinery is operating within safe vibration limits, the 3500/15-01-02-01 helps prevent accidents and injuries in industrial settings.

Related Models:

- Bently Nevada 3500/15-04-02-01

- Bently Nevada 3500/15-02-01

- Bently Nevada 3500/60

- Bently Nevada 3500/05-01-02-00-00-00

- Bently Nevada 3500/15-02-02-00

- Bently Nevada 3500/15-03-04

- Bently Nevada 3500/15-02-03-00

- Bently Nevada 3500/15-04-04-01

- Bently Nevada 3500/15-01-03-00

- Bently Nevada 3500/15-02

In conclusion, the Bently Nevada 3500/15-01-02-01 is a top-of-the-line vibration monitoring system that offers advanced features, reliable performance, and ease of use. Whether in the power industry, petrochemical plants, or general automation applications, this model is an essential tool for maintaining equipment health and ensuring smooth operations.

The Bently Nevada 3500/15-01-02-01 is a highly reliable and versatile vibration monitoring system designed for use in the power industry, petrochemical plants, and general automation applications. With its advanced features and robust construction, this model is a popular choice among professionals in these industries.

Key Features:

- Real-time vibration monitoring: The 3500/15-01-02-01 continuously monitors vibrations in machinery and equipment, providing real-time data to help prevent potential failures.

- Data analysis capabilities: This model is equipped with sophisticated data analysis tools that allow users to identify patterns and trends in vibration data, enabling predictive maintenance strategies.

- Remote monitoring: The 3500/15-01-02-01 can be accessed remotely, allowing users to monitor equipment health from anywhere, at any time.

- High accuracy sensors: This model comes with high-quality sensors that provide accurate vibration measurements, ensuring reliable performance.

- Easy installation and setup: The 3500/15-01-02-01 is designed for easy installation and setup, saving time and effort during implementation.

Typical Usage Scenarios:

- Power industry: In power plants, the 3500/15-01-02-01 is used to monitor the vibration levels of turbines, generators, and other critical equipment to prevent unexpected failures and downtime.

- Petrochemical plants: In petrochemical facilities, this model helps monitor the condition of pumps, compressors, and other machinery to ensure safe and efficient operations.

- General automation: In various automation applications, the 3500/15-01-02-01 is used to monitor the health of rotating equipment, reducing maintenance costs and improving overall system reliability.

Basic Advantages:

- Early fault detection: The 3500/15-01-02-01 helps detect potential faults in machinery before they escalate into major problems, saving time and money on repairs.

- Increased equipment lifespan: By monitoring vibration levels and identifying issues early on, this model helps extend the lifespan of equipment and reduce the risk of unexpected failures.

- Improved safety: By ensuring that machinery is operating within safe vibration limits, the 3500/15-01-02-01 helps prevent accidents and injuries in industrial settings.

Related Models:

- Bently Nevada 3500/15-04-02-01

- Bently Nevada 3500/15-02-01

- Bently Nevada 3500/60

- Bently Nevada 3500/05-01-02-00-00-00

- Bently Nevada 3500/15-02-02-00

- Bently Nevada 3500/15-03-04

- Bently Nevada 3500/15-02-03-00

- Bently Nevada 3500/15-04-04-01

- Bently Nevada 3500/15-01-03-00

- Bently Nevada 3500/15-02

In conclusion, the Bently Nevada 3500/15-01-02-01 is a top-of-the-line vibration monitoring system that offers advanced features, reliable performance, and ease of use. Whether in the power industry, petrochemical plants, or general automation applications, this model is an essential tool for maintaining equipment health and ensuring smooth operations.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|