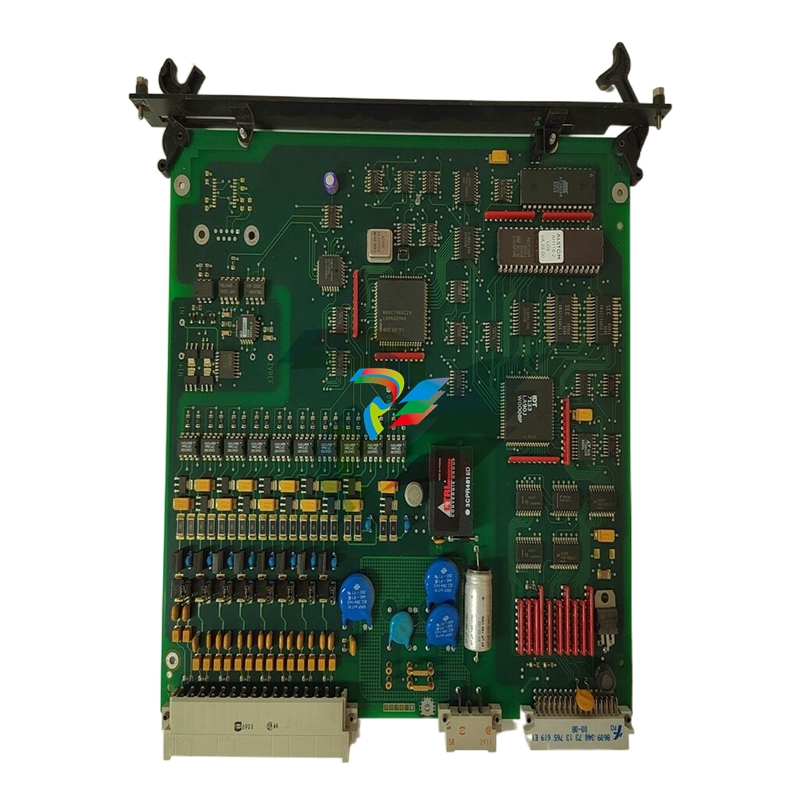

CONVERTEAM ATM090-L4B14 - / ATM090L4B14

The CONVERTEAM ATM090-L4B14 stands as a robust and highly efficient automation solution engineered for demanding environments within the power industry, petrochemical sector, and general automation applications. Designed to meet rigorous operational standards, the ATM090-L4B14 offers exceptional input/output (I/O) capacity, reliable durability, and superior performance metrics, making it a preferred choice for industrial automation professionals seeking long-term operational stability and precision.

At its core, the CONVERTEAM ATM090-L4B14 features a high-capacity input/output structure capable of handling complex control signals and power loads with remarkable efficiency. It supports a wide input voltage range, ensuring stable operation even under fluctuating power conditions commonly encountered in large-scale power plants and petrochemical facilities. The output stage excels in delivering consistent power with minimal losses, enabling seamless integration with heavy-duty industrial machinery and process control systems. Its rugged construction guarantees resilience against harsh environmental factors such as temperature extremes, vibration, and electromagnetic interference, which are critical considerations in power generation and chemical processing plants.

One of the standout aspects of the ATM090-L4B14 is its advanced thermal management system, which maintains optimal operating temperatures even during extended cycles of high load. This capability significantly reduces downtime and maintenance costs by preventing overheating and associated component failures. Additionally, the device incorporates cutting-edge digital diagnostics and control features, allowing operators to monitor system health in real time and execute preventive maintenance strategies proactively.

In practical terms, the CONVERTEAM ATM090-L4B14 excels in several real-world applications. Within the power industry, it is ideal for managing turbine control systems, grid stabilization modules, and energy distribution automation. Its precision and responsiveness help optimize power output and enhance grid reliability. In petrochemical plants, the ATM090-L4B14 is deployed for process automation tasks such as catalytic reactor control and safety shutdown systems, where timing accuracy and fail-safe performance are critical. For general automation, the device provides a dependable backbone for assembly line robotics, conveyor systems, and environmental monitoring stations, delivering consistent control and diagnostics that improve overall operational efficiency.

When compared to other products within the CONVERTEAM portfolio, the ATM090-L4B14 distinguishes itself through its enhanced I/O scalability and superior environmental tolerance. Models such as the CONVERTEAM 51199-005-00 and the CONVERTEAM VAA23ZG750BA offer specialized functions in power conversion and signal processing, but the ATM090-L4B14 provides a more comprehensive solution for integrated automation needs. Unlike the CONVERTEAM Micom P743 or the CONVERTEAM S98101/106, which focus primarily on protection relays or communication protocols, the ATM090-L4B14 delivers a balanced combination of power handling and control versatility.

Alongside the CONVERTEAM ATM090-L4B14, we also offer complementary models like the CONVERTEAM RTx-151, which enhances remote telemetry capabilities, and the CONVERTEAM MVAJ105JA1002A, known for its precision voltage regulation. The CONVERTEAM 20X4284/20A and the CONVERTEAM VAG21ZG8002ADCH serve as excellent adjuncts for power conversion and motor control applications, respectively. For users requiring specialized diagnostic tools, the CONVERTEAM p141316a6m0440j and the CONVERTEAM p44291ab6m0720m provide advanced monitoring solutions. Additionally, the CONVERTEAM Un Serie DYNAMIC and the CONVERTEAM 70SI01 cater to dynamic load management and switching requirements within complex automation networks.

Selecting the CONVERTEAM ATM090-L4B14 means investing in a product that embodies reliability, precision, and adaptability. Its design reflects the brand’s commitment to supporting critical infrastructure sectors through innovative technology that drives operational excellence. Whether deployed in hydroelectric plants, oil refineries, or automated manufacturing lines, the ATM090-L4B14 consistently delivers the performance demanded by today’s automation challenges.

In summary, the CONVERTEAM ATM090-L4B14 is an indispensable asset for professionals seeking advanced automation products tailored to the power industry, petrochemical sector, and general automation applications. Its robust I/O capacity, exceptional durability, and comprehensive feature set provide a competitive edge over other CONVERTEAM models, ensuring optimized system performance and operational reliability. Explore how the ATM090-L4B14 and its complementary counterparts like the CONVERTEAM Micom P139 and the CONVERTEAM EPSC-0070 can elevate your automation infrastructure to new levels of efficiency and control.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|