DCS; Industrial control system

Product

Article

NameDescriptionContent

Argument

Current Location:

PRODUCT SHOW

Description

**GE IC200ACC302: Advanced Automation Control for Industrial Applications**

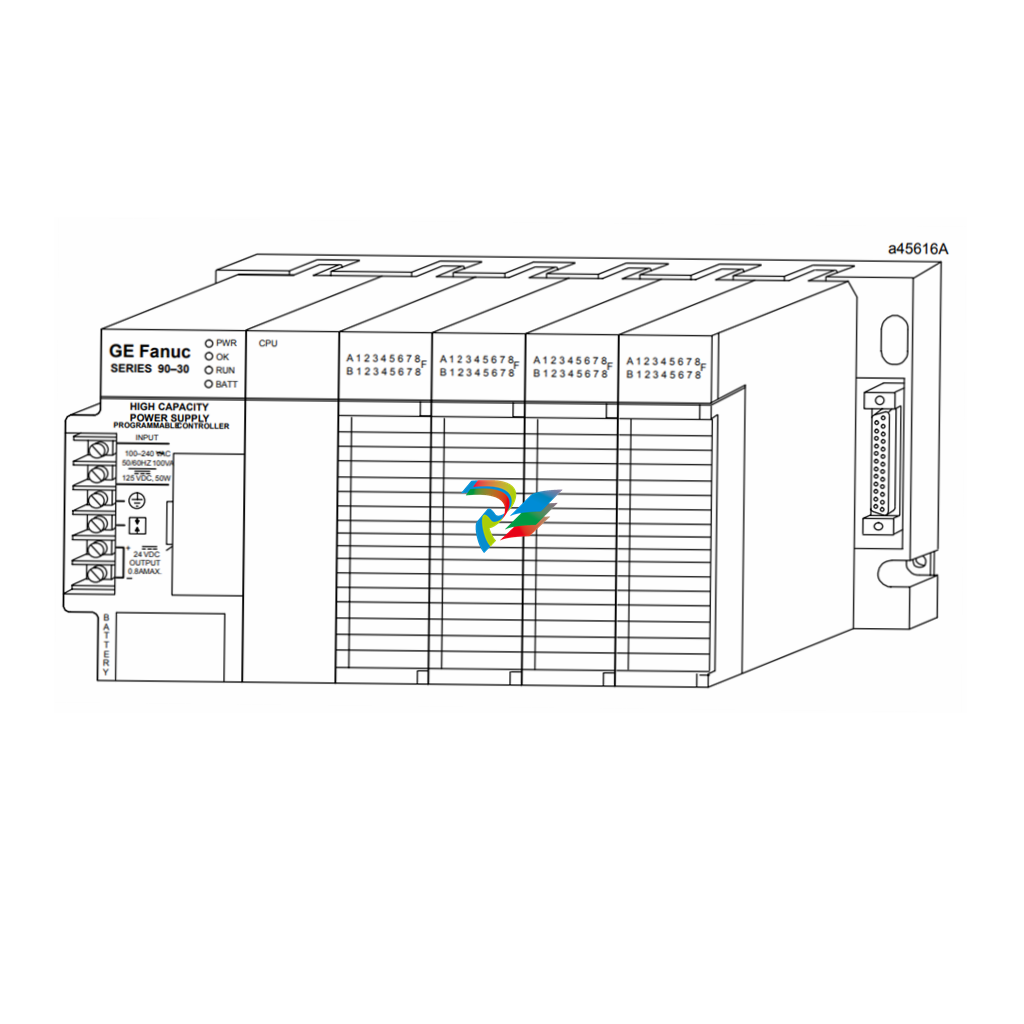

GE IC200ACC302 - Analog I/O control module

GE IC200ACC302 - Analog I/O control module

**GE IC200ACC302: Advanced Automation Control for Industrial Applications**

The GE IC200ACC302 is a state-of-the-art automation controller designed to meet the demanding requirements of the power industry, petrochemical sector, and general automation applications. Offering a robust input/output capacity, the IC200ACC302 ensures seamless integration and exceptional performance in a variety of operational environments. With an impressive durability rating, this model is engineered to withstand the rigors of industrial use, making it a reliable choice for critical applications.

**Key Technical Features:**

The GE IC200ACC302 features a versatile architecture that supports extensive I/O configurations, accommodating up to 256 digital inputs and 256 digital outputs. This high capacity allows for precise control and monitoring of processes, ensuring efficiency and reliability in complex systems. The controller operates effectively within a temperature range of -20°C to 60°C, showcasing its adaptability in various environmental conditions. Additionally, the IC200ACC302 is designed with enhanced processing speed and memory capabilities, allowing for rapid data handling and processing, which significantly improves overall system performance.

**Real-World Usage Scenarios:**

The application of IC200ACC302 in the power industry is particularly notable, where it is utilized in the management of electrical generation and distribution systems. Its ability to handle large volumes of data and control multiple inputs and outputs enables operators to maintain optimal performance and safety standards. In the petrochemical sector, the IC200ACC302 excels in process automation, where precise control of chemical mixing and temperature regulation is critical. Moreover, its robust architecture supports general automation tasks, such as assembly line control and material handling, making it an essential component in various industrial settings.

**Comparison with Other GE Models:**

When compared to other models within the GE lineup, such as the GE IC200MDL742H and GE IC693MDL644RR, the IC200ACC302 stands out due to its superior I/O capacity and processing speed. While the GE IC200MDL742H is excellent for standard applications, it lacks the extensive input/output support offered by the IC200ACC302. The GE IC693MDL644RR, although reliable, does not match the advanced durability and performance metrics of the IC200ACC302. This makes the IC200ACC302 a more versatile choice for users seeking a comprehensive control solution in challenging environments.

**Complementary GE Models:**

The GE IC200ACC302 works harmoniously with other GE automation products, enhancing its functionality and broadening its application scope. For instance, the GE IC200MDL742H serves as an ideal expansion module, allowing users to increase I/O capacity effortlessly. The GE AI801 provides analog input capabilities, complementing the digital control features of the IC200ACC302. Additionally, the GE DS3800HMPA1A1 and GE DS200GSIAG1C models can be integrated to facilitate advanced communication and data exchange between systems.

Moreover, the GE IC800PSHV011 serves as a power supply unit that ensures the IC200ACC302 operates under optimal conditions. The GE 8V1022.00-2, with its advanced signal processing capabilities, further enhances the operational efficiency of the IC200ACC302. For users requiring enhanced safety and monitoring, the GE DS200PCCAG6A provides critical process control functionalities.

In summary, the GE IC200ACC302 is a cutting-edge automation controller that excels in the power industry, petrochemical applications, and general automation tasks. Its high input/output capacity, exceptional durability, and superior performance metrics make it an indispensable asset for industrial operations. By integrating with related models such as the GE IC200MDL742H, GE AI801, and GE IC800PSHV011, users can create a comprehensive automation solution tailored to their specific needs. Choose the GE IC200ACC302 for unparalleled efficiency and reliability in your automation projects.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Customer Reviews

Satisfaction :

5 Stars

No evaluation information