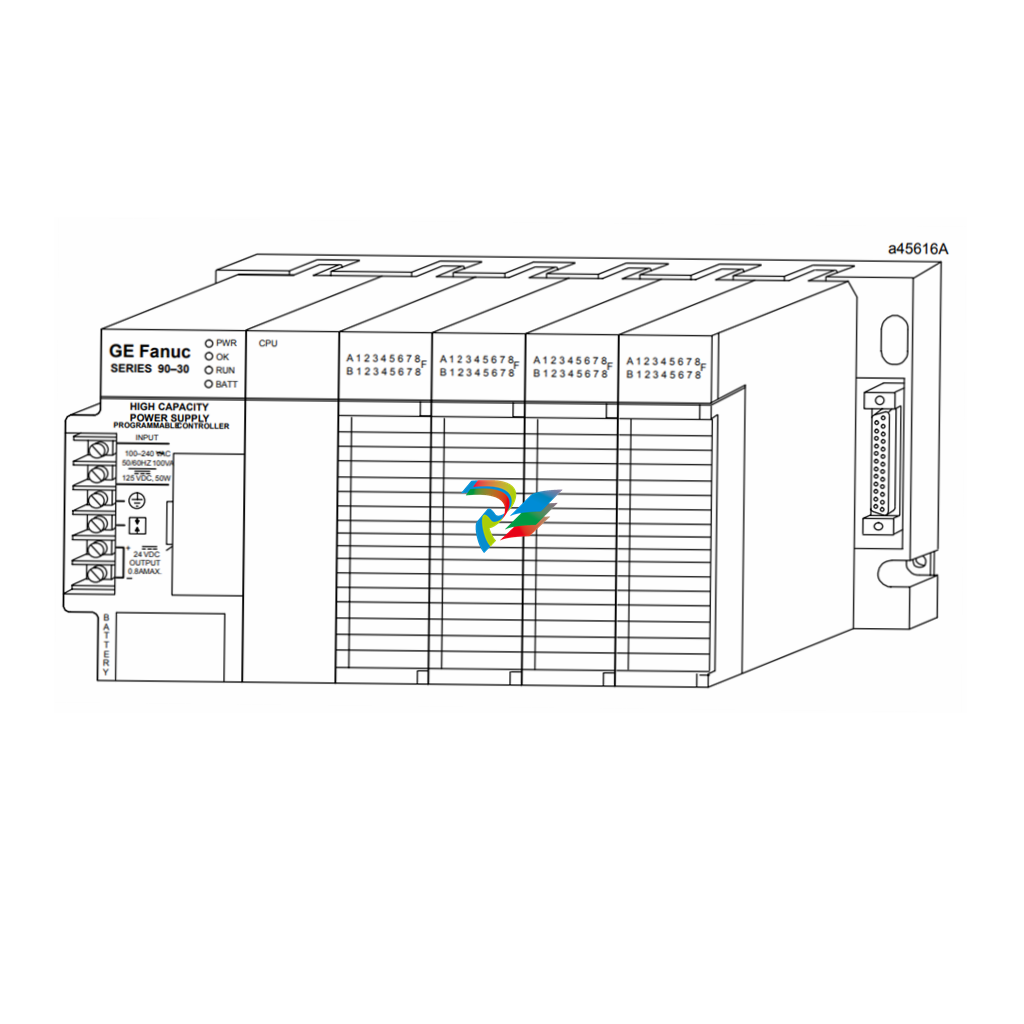

GE IC693MDL241 - Positive/Negative Input Module High Performance Analog Input for Industrial Automation

The GE IC693MDL241 is a high-performance digital I/O module designed to meet the demanding needs of modern automation systems across various industries, including power generation, petrochemical processing, and general manufacturing. Engineered for durability and reliability, this module offers a robust solution for complex control applications requiring extensive input/output capabilities and precise data management.

Key technical features of the GE IC693MDL241 include its impressive I/O capacity, supporting up to 24 discrete inputs and 24 discrete outputs, enabling seamless integration into large-scale automation networks. Its high-speed digital processing ensures rapid response times essential for critical control tasks, while its rugged construction guarantees durability in harsh industrial environments characterized by vibration, extreme temperatures, and electrical noise. The module's design emphasizes longevity, with a proven mean time between failures (MTBF) that aligns with stringent industrial standards, ensuring consistent operation over extended periods with minimal maintenance.

In real-world scenarios, the GE IC693MDL241 excels in applications such as power plant control systems where reliable data acquisition from multiple sensors is vital, or in petrochemical plants where precise control of process variables is crucial for safety and efficiency. Its fast I/O response makes it ideal for controlling safety interlocks, monitoring critical parameters, and managing complex automation sequences. Additionally, in general automation settings, the module supports extensive machine automation with high-density input/output configurations, reducing the need for multiple modules and simplifying system architecture.

Compared to other models within the GE product lineup, such as the GE IC695ACC302 or the GE IC695CPU315, the IC693MDL241 specializes in providing a high-density digital I/O solution that can be integrated seamlessly with programmable automation controllers (PACs) and other control modules like the GE IC200CHS002 or the GE IS220PDIAH1BE. For instance, while the GE DS200TCPDG1BEC offers advanced communication capabilities, the IC693MDL241 focuses on delivering reliable digital I/O performance, making it an excellent choice for expanding existing control systems. Similarly, models like the GE DS3800HMPK1F1B and GE IS200SPROH1A serve complementary roles, with the former providing motion control and the latter offering process input/output, enabling comprehensive automation solutions.

The application of IC693MDL241 in power industry, petrochemical, and general automation environments makes it a versatile component for engineers seeking robust, scalable, and reliable I/O modules. Its compatibility with a range of GE automation products ensures seamless integration, whether used in standalone systems or complex distributed control architectures. Alongside the GE IS200UCVEH2A or the GE IS200SPROH1A, the IC693MDL241 helps streamline operations, improve data accuracy, and enhance system responsiveness.

In summary, the GE IC693MDL241 stands out among GE automation products as a durable, high-capacity digital I/O module optimized for demanding industrial applications. Its combination of extensive input/output support, rugged design, and fast processing makes it a preferred choice for industries requiring reliable automation solutions. When paired with other GE models like the GE IC695ACC302 or the GE IC697CPM925, it contributes to creating flexible and efficient control systems capable of meeting the evolving challenges of power, petrochemical, and industrial automation sectors. The application of IC693MDL241 is especially valued where high-density digital I/O, durability under harsh conditions, and seamless integration are paramount, ensuring operational excellence and safety across critical industrial environments.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|