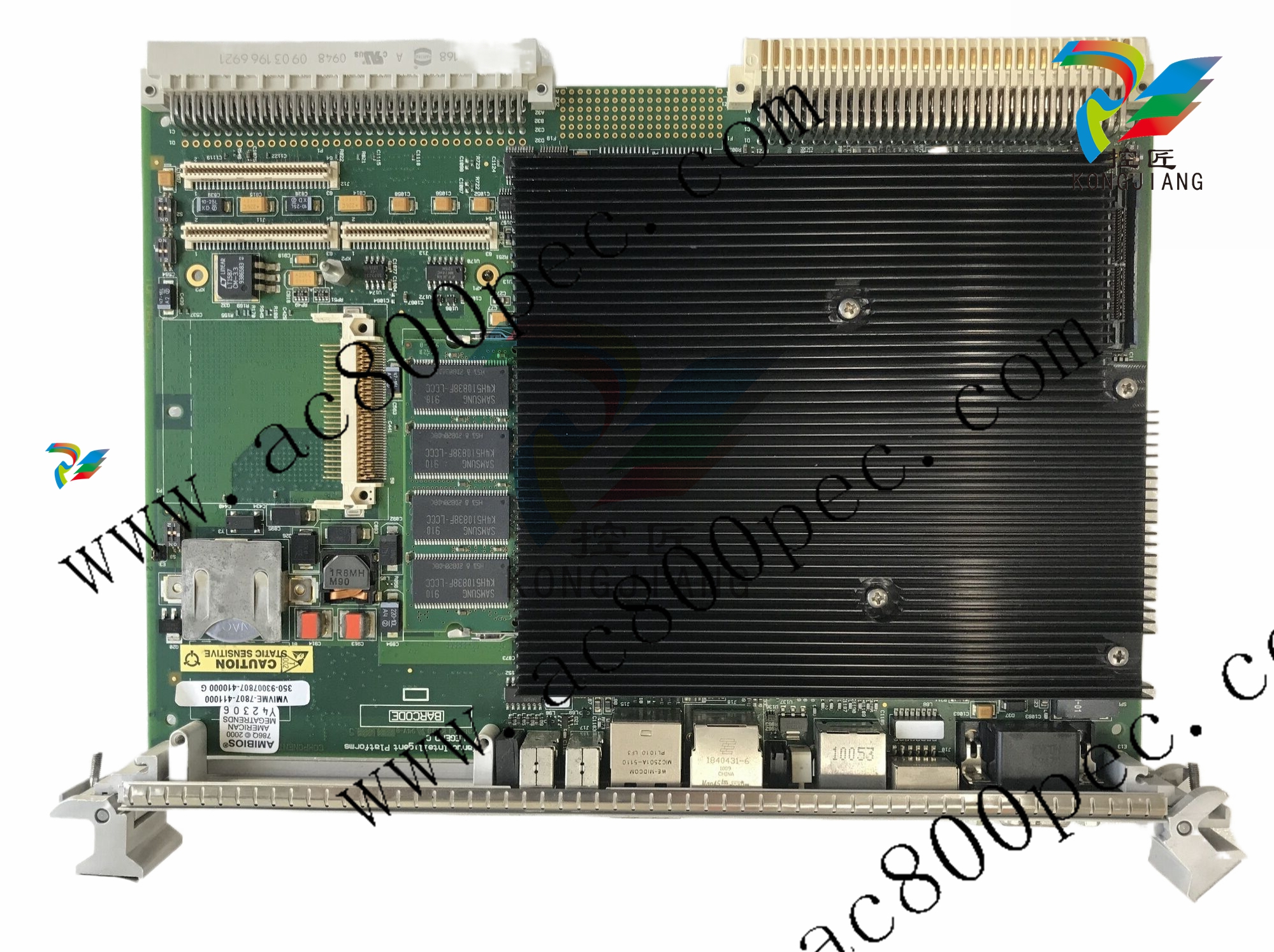

Honeywell X-NPMS(H) - Network Paging Console Fire Equipment

The Honeywell X-NPMS(H) stands out as a premier solution within Honeywell’s extensive portfolio of automation products, designed specifically to meet the demanding needs of the power industry, petrochemical sectors, and general automation applications. Engineered for precision, durability, and seamless integration, the X-NPMS(H) combines advanced input/output capabilities with robust performance metrics that ensure reliable operation in the most challenging environments.

At its core, the Honeywell X-NPMS(H) offers a versatile input/output capacity that can handle multiple sensor signals and control outputs simultaneously, enabling complex process monitoring and control with exceptional accuracy. Its modular architecture supports both analog and digital signals, providing flexibility for a wide range of automation tasks. The device boasts an impressive data acquisition rate with minimal latency, ensuring real-time responsiveness critical for applications such as power plant control systems or petrochemical process monitoring. Additionally, the X-NPMS(H) is built with high-grade materials and advanced protective coatings, granting it superior resistance to harsh conditions like extreme temperatures, corrosive substances, and mechanical vibration. This durability ensures extended operational life and reduced downtime, vital for continuous industrial processes.

In real-world scenarios, the Honeywell X-NPMS(H) excels where precision and reliability are non-negotiable. Within the power industry, it facilitates seamless integration with control systems managing turbines, generators, and substations, optimizing energy output while maintaining safety and regulatory compliance. In petrochemical plants, the X-NPMS(H) enables accurate monitoring of pressure, temperature, and flow rates, preventing hazardous incidents through early detection of anomalies. For general automation, it supports complex manufacturing lines and process automation where consistent data handling and control precision directly impact productivity and quality.

When compared to other Honeywell models, the X-NPMS(H) offers distinct advantages that make it a preferred choice for critical industrial applications. For instance, while the Honeywell MCT202 and Honeywell 4DP7APXPR311 provide reliable sensor interfacing and basic process control, the X-NPMS(H) surpasses them with enhanced input/output versatility and faster response times. Contrasted with the Honeywell Q9200A-1005 and Honeywell DE131-0-A-B0-0-Z-1-0B,0C-EE0-000, which are tailored more towards specific control scenarios, the X-NPMS(H) offers broader applicability and modular expansion options. Furthermore, its ruggedized design places it ahead of models like the Honeywell 51305890-175 and Honeywell 965-0976-040-219-219, which, while robust, may not withstand the same level of environmental stress encountered in petrochemical or power plant settings.

Alongside the Honeywell X-NPMS(H), Honeywell offers complementary automation solutions such as the Honeywell AD650H for high-precision analog control, the Honeywell EX-DGM506 for enhanced diagnostic monitoring, and the Honeywell IC500 series for integrated control networking. The Honeywell ST3000 system pairs well with the X-NPMS(H) for comprehensive process automation, while the Honeywell RA890G-1260 and Honeywell RA890G1229 serve as reliable interface modules that enhance signal processing capabilities. For extended system management, the Honeywell WEB-700 provides user-friendly visualization and control, and the Honeywell AZ800 enriches communication protocols within complex automation networks. Additionally, the Honeywell 2119020-8000 offers advanced sensor input options that complement the X-NPMS(H)’s functionality.

The application of the Honeywell X-NPMS(H) in the power industry, petrochemical, and general automation sectors is a testament to its engineered excellence. Whether it is ensuring the safe operation of a gas processing unit, optimizing the output of a thermal power station, or automating a manufacturing assembly line, the X-NPMS(H) delivers unmatched performance and reliability. Its ability to integrate smoothly with other Honeywell automation products enhances system efficiency and reduces the complexity of industrial control architectures.

In summary, the Honeywell X-NPMS(H) is a cornerstone device within Honeywell’s automation lineup, combining superior input/output capabilities, rugged durability, and exceptional performance metrics tailored for critical industrial processes. When paired with complementary models such as the Honeywell MCT202, Honeywell AD650H, Honeywell ST3000, and Honeywell EX-DGM506, it offers a comprehensive solution that addresses the evolving demands of modern power, petrochemical, and general automation industries. For organizations seeking reliable, high-performance automation products, the Honeywell X-NPMS(H) represents an optimal balance of technological sophistication and operational resilience.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|