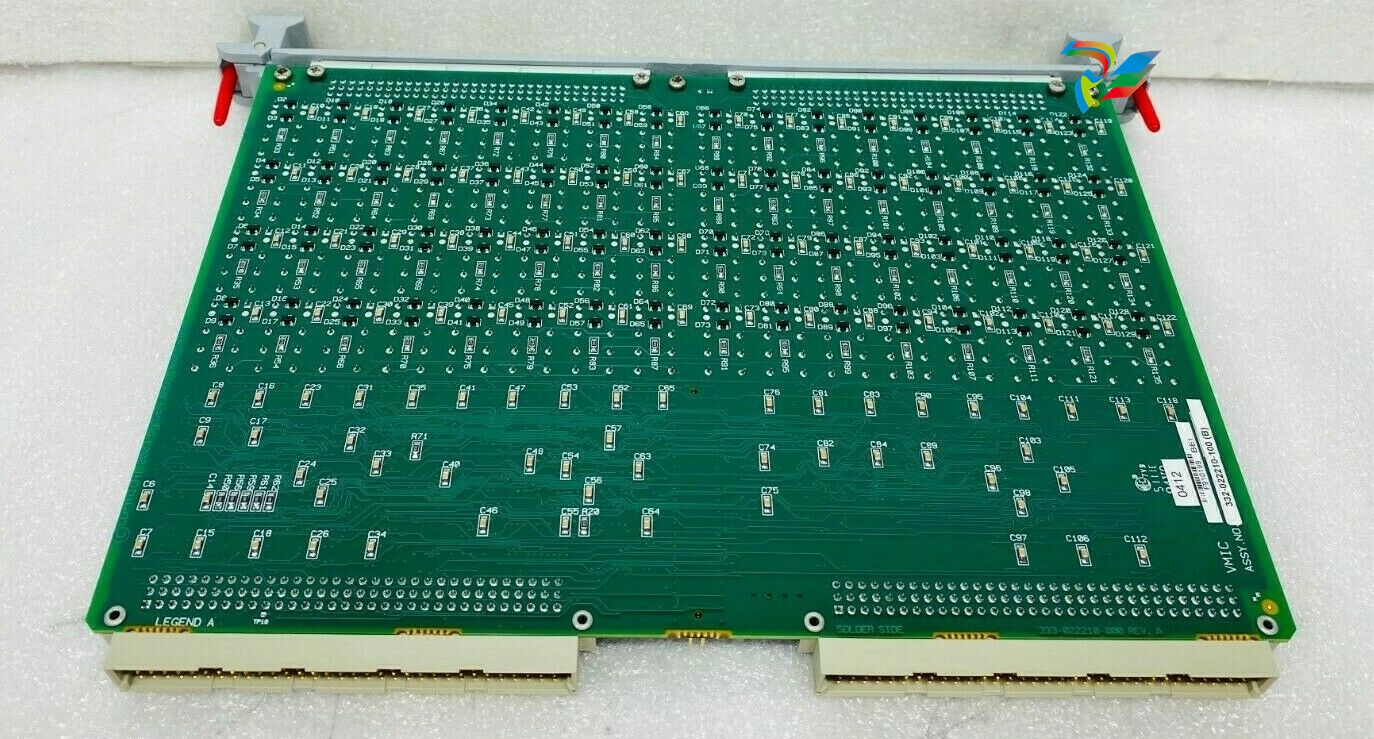

Honeywell 10020/1/2 - / 1002012 (NEW IN BOX)

The Honeywell 10020/1/2 stands as a robust and reliable solution engineered to meet the rigorous demands of the power industry, petrochemical plants, and general automation environments. This model is designed with a focus on exceptional input/output capacity, durability, and high-performance metrics that ensure consistent operation even under challenging industrial conditions.

At its core, the Honeywell 10020/1/2 offers advanced signal processing capabilities with a versatile input/output configuration that supports both analog and digital signals. This flexibility allows seamless integration with a wide range of sensors and control systems commonly found in power generation and petrochemical facilities. Its input channels are optimized for precision measurement, supporting high-resolution data acquisition with minimal latency, which is crucial for real-time monitoring and control. The output interfaces ensure reliable communication with downstream devices, facilitating automated responses and system adjustments that enhance operational efficiency.

Durability is a cornerstone of the Honeywell 10020/1/2. Designed to withstand harsh industrial environments, it features a rugged enclosure with high resistance to temperature fluctuations, moisture, and vibration. This resilience makes it ideal for deployment in petrochemical plants where exposure to corrosive substances and extreme conditions is commonplace. Moreover, the unit complies with stringent industry standards, ensuring safety and longevity, which reduces downtime and maintenance costs.

Performance-wise, the Honeywell 10020/1/2 excels through its rapid response times and consistent accuracy, key for applications that demand precise control such as turbine monitoring in power plants or chemical process automation. Its robust firmware supports advanced diagnostics and self-monitoring features, enabling predictive maintenance and minimizing the risk of unexpected failures.

In real-world applications, the 10020/1/2 is particularly effective in power industry scenarios such as generator control, switchgear automation, and substation monitoring. In petrochemical plants, it supports process control systems by providing reliable data interfaces for flow meters, pressure sensors, and temperature controllers. For general automation, it integrates effortlessly with programmable logic controllers (PLCs) and distributed control systems (DCS), offering scalable performance that can adapt to evolving operational needs.

When compared with other Honeywell automation products, the 10020/1/2 stands out for its balanced combination of input/output versatility and environmental durability. For instance, while the Honeywell BK-G100 and Honeywell BK-G40 offer specialized sensor solutions, they lack the comprehensive I/O flexibility and ruggedness found in the 10020/1/2. Similarly, the Honeywell MC-PDIS12 and Honeywell DMX-A-6212 excel in digital signal processing but do not match the 10020/1/2’s broader analog integration capabilities. The Honeywell 965-0976-040-219-219 and Honeywell 107843 are excellent for specific control tasks but are less adaptable to the diverse sensor inputs handled by the 10020/1/2.

Alongside the Honeywell 10020/1/2, we also offer complementary models like the Honeywell 620-0025RC and Honeywell SPS5785, which provide enhanced signal conditioning and power supply options, respectively. The Honeywell CC-PCNT01 and Honeywell 30754471-001 serve as auxiliary modules that expand system connectivity and monitoring capabilities, further enriching the automation ecosystem. For applications requiring specialized control, the Honeywell HIMA-6E-B and Honeywell 51400669-100 bring additional safety and processing features that complement the core functions of the 10020/1/2.

The application of 10020/1/2 in power industry, petrochemical, and general automation sectors is a testament to Honeywell’s commitment to delivering durable, high-performing automation products. Whether deployed in large-scale power plants or complex chemical processing units, the 10020/1/2 ensures seamless integration, precise control, and reliable operation. Its adaptability and rugged design make it a preferred choice among engineers seeking dependable automation solutions.

In summary, the Honeywell 10020/1/2 is a versatile, durable, and performance-driven automation product that meets the exacting standards of industrial applications. When paired with other Honeywell models such as the Honeywell ASDX015D44R sensor modules or the Honeywell MP-DNCF02-200 control units, it forms part of a comprehensive automation portfolio designed to optimize operational efficiency and reliability. For industries looking to enhance their automation infrastructure, the Honeywell 10020/1/2 offers a proven, future-ready solution tailored to complex industrial environments.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|