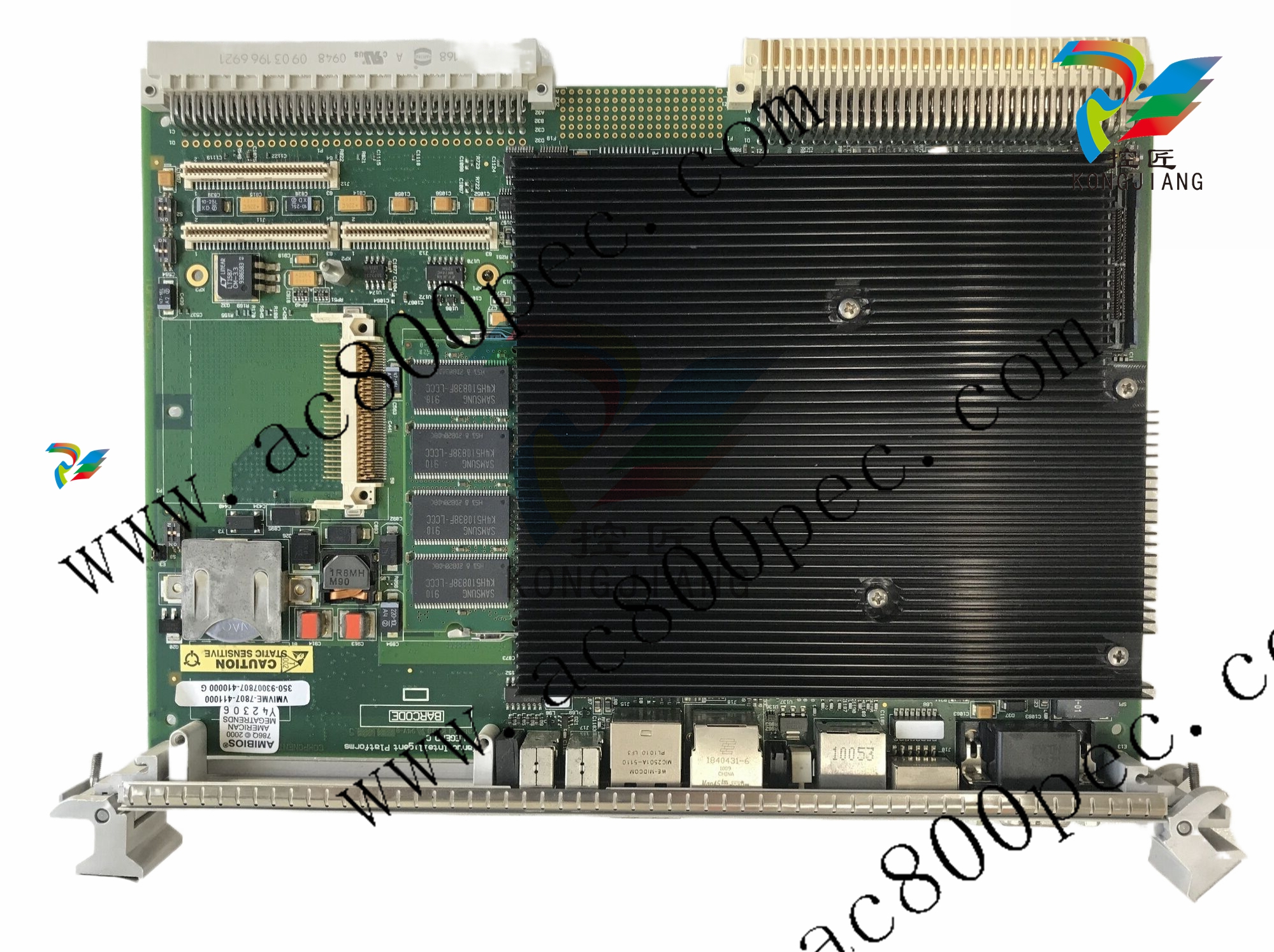

Honeywell K4LCN-16 - 51403519-160 MEMORY PROCESSOR MODULE BOARD TDC 3000

The Honeywell K4LCN-16 is a highly reliable automation controller designed to meet the rigorous demands of the power industry, petrochemical plants, and general automation environments. Engineered with precision, this model offers exceptional input/output capacity, robust durability, and superior performance metrics that position it as a cornerstone solution for critical industrial applications.

At its core, the Honeywell K4LCN-16 features an advanced I/O architecture capable of managing up to 16 channels simultaneously, ensuring seamless data acquisition and control across complex processes. Its architecture supports both analog and digital inputs and outputs, allowing for versatile integration with a broad spectrum of sensors, actuators, and control devices. The controller’s high processing speed and real-time response capabilities ensure rapid decision-making and system adjustments vital for maintaining operational continuity in demanding environments.

Durability is a hallmark of the K4LCN-16. Built to withstand harsh industrial conditions, it boasts an industrial-grade enclosure and components rated for extended temperature ranges, high humidity, and resistance to vibration and electrical noise. This resilience makes it an ideal choice for power plants, where equipment is exposed to extreme temperatures and continuous operation stresses, as well as in petrochemical facilities where hazardous environments require stringent safety and reliability standards.

Performance-wise, the Honeywell K4LCN-16 offers unmatched stability and precision. Its integrated diagnostics and fault-tolerant design reduce downtime by enabling predictive maintenance and quick troubleshooting. The controller supports multiple communication protocols, facilitating easy integration into existing automation networks. This flexibility ensures the K4LCN-16 can serve as the backbone for complex control systems, from turbine management in power generation to process control in chemical manufacturing.

In real-world applications, the Honeywell K4LCN-16 excels where precision and reliability are non-negotiable. For example, in the power industry, it can be utilized to monitor and control turbine operations, manage load distribution, and oversee safety interlocks. In petrochemical settings, the controller ensures accurate chemical dosing, temperature regulation, and emergency shutdown procedures, helping to maintain safety and efficiency. In general automation, it supports assembly line control, robotic coordination, and environmental monitoring, demonstrating its adaptability across diverse industrial landscapes.

When compared to other Honeywell automation products, the K4LCN-16 stands out due to its balanced combination of I/O capacity, rugged design, and real-time processing power. While models like the Honeywell RM7800L1012 and Honeywell CC-PAIX02 offer specialized functions in sensing and protocol conversion respectively, the K4LCN-16 provides a more comprehensive automation solution suitable for both control and monitoring tasks. Unlike the Honeywell BCU370QFEU0D1, which is primarily a building control unit, the K4LCN-16 is designed specifically for industrial process control, delivering enhanced durability and performance under demanding conditions.

The K4LCN-16 also complements a wide range of Honeywell products such as the Honeywell 620-0073 sensor modules, Honeywell J-MHM10 interface units, and Honeywell TSENALMOX-05682 temperature sensors, creating a fully integrated automation ecosystem. Additionally, it pairs well with communication modules like the Honeywell CC-IP0101 and the Honeywell CC-PCNT02, enabling seamless data exchange within industrial networks. For system monitoring and human-machine interface needs, the Honeywell MCDU860 and Honeywell TH8320U1008 provide powerful visualization tools that enhance operator interaction with the K4LCN-16-controlled processes.

The application of the Honeywell K4LCN-16 in the power industry, petrochemical, and general automation is further supported by its adherence to rigorous industry standards and its capacity to integrate into large-scale distributed control systems. Alongside Honeywell automation products such as the Honeywell DR45AT-1100-40-001-0-10N000-0 actuator controls and Honeywell 2119020-8000 pressure transmitters, the K4LCN-16 forms a critical component of modern industrial automation strategies aimed at optimizing safety, efficiency, and reliability.

In summary, the Honeywell K4LCN-16 is an indispensable automation controller that combines extensive I/O capabilities, rugged construction, and high performance to meet the stringent requirements of the power, petrochemical, and general automation sectors. Its compatibility with a broad range of Honeywell devices and systems ensures comprehensive process control and monitoring, making it a top choice for industries striving for operational excellence and long-term reliability. Whether deployed alongside the Honeywell MU-PSIM11 power supply modules or integrated with the Honeywell 30-3013 safety relays, the K4LCN-16 stands as a testament to Honeywell’s commitment to delivering advanced automation solutions designed for today’s industrial challenges.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|