Honeywell R295 - Bandy Backflow hp-Fa New

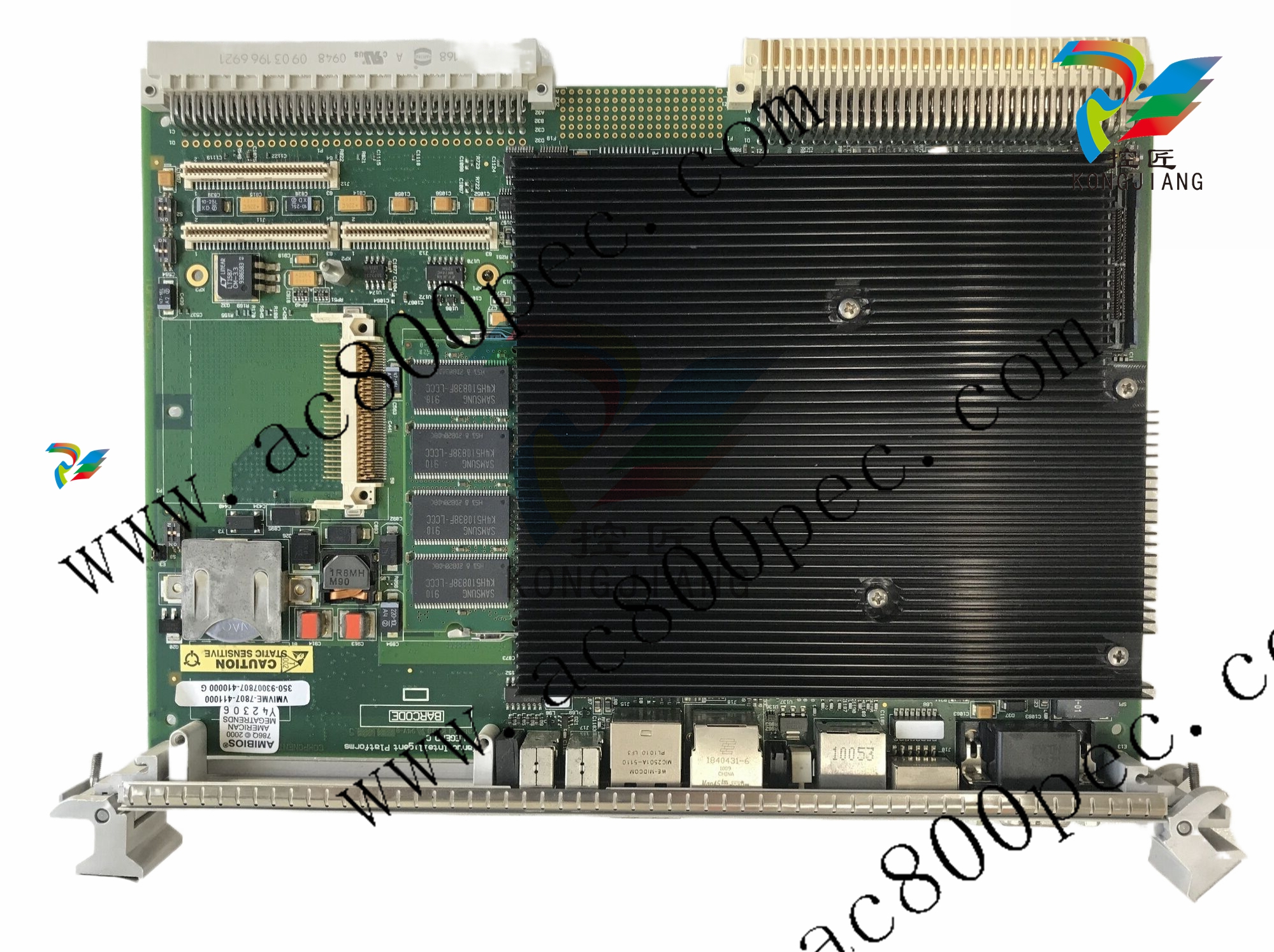

The Honeywell R295 is a robust and versatile automation solution designed to meet the demanding requirements of the power industry, petrochemical plants, and general automation environments. Engineered for exceptional reliability and high-performance operation, the R295 stands out with its advanced input/output (I/O) capacity, durability, and precision control capabilities, making it an indispensable component in critical industrial applications.

At the core of the Honeywell R295’s technical excellence is its comprehensive I/O interface, which supports a wide array of analog and digital signals. This flexibility allows seamless integration with various sensors, actuators, and control devices, ensuring precise monitoring and control in real-time. The R295 supports high-speed data acquisition and processing, with a response time optimized for rapid system feedback, which is vital in environments where milliseconds matter, such as in power generation or chemical processing. Its rugged construction features industrial-grade materials and conforms to stringent environmental standards, offering resistance to shock, vibration, temperature extremes, and electromagnetic interference. This durability translates into long service life and minimal downtime, critical in continuous operation industries.

In real-world scenarios, the Honeywell R295 excels in applications requiring reliable automation under harsh conditions. In the power industry, it is often deployed for turbine control, generator excitation, and grid management tasks, where its high-precision control algorithms enhance operational efficiency and safety. Petrochemical plants benefit from the R295’s ability to monitor complex processes involving temperature, pressure, and flow control, ensuring product quality and compliance with safety regulations. Additionally, its application in general automation includes factory automation lines, HVAC control systems, and water treatment facilities, where it delivers consistent performance and scalability. The R295’s compatibility with Honeywell’s ST3000 and ACX631 control platforms further enhances its integration capabilities, forming a cohesive automation ecosystem that streamlines process management and optimizes productivity.

When compared to other Honeywell automation products, the R295 offers unique advantages that make it a preferred choice for many industrial operators. For instance, while the Honeywell 9243201 and 900C70-0360-00 models provide excellent control functionalities, they are often tailored to more specialized or limited I/O applications. The R295, with its broader I/O capacity and faster processing speeds, offers greater flexibility and scalability. In contrast to the Honeywell 9907-1199 and 51303940-250, which are optimized for specific sensor interfacing, the R295 balances sensor integration with advanced control logic, enabling it to serve as both a data acquisition unit and a control processor. Moreover, the R295’s ruggedness surpasses models like the Honeywell 30752783-001, making it more suitable for extreme industrial environments.

Alongside the Honeywell R295, complementary models such as the Honeywell RCZ851K and Honeywell 2075252-D2 provide additional capabilities for system diagnostics and network communication, respectively. The Honeywell 2586689-902 and Honeywell FC-SCNT01 serve well in auxiliary sensor and signal conditioning roles, enhancing the overall automation solution. Integration with the Honeywell WEB-600E controller enables remote monitoring and advanced data analytics, further extending the R295’s functionality. For applications requiring enhanced safety protocols, the Honeywell DR45AT-1100-00-001-0-600000-0 and DR45AT-1111-00-000-0-RA0P00-0 safety relays complement the R295’s control features, ensuring compliance with industry standards.

The application of the Honeywell R295 in power industry, petrochemical, and general automation sectors is underpinned by its adaptability and robust design. It supports critical infrastructure with minimal maintenance, reducing operational risks and costs. Honeywell automation products like the R295 are supported by a global service network, ensuring that users receive expert assistance and timely upgrades. Whether deployed in a power plant’s control room or integrated into a petrochemical process line, the R295 delivers dependable performance, enabling operators to maintain control and optimize production outcomes efficiently.

In summary, the Honeywell R295 offers a powerful blend of advanced technical features, rugged durability, and versatile application potential. Its superior I/O capacity, fast processing, and compatibility with Honeywell’s broader automation portfolio—including models like the ST3000, ACX631, 9243201, and RCZ851K—make it an ideal solution for industries requiring high-reliability automation. For professionals seeking dependable control systems in power generation, petrochemical processing, and general automation, the Honeywell R295 stands out as a benchmark for performance and innovation.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|