Honeywell WU650 - Radar RTA 7008470-922 w/ March 2024 Overhauled 8130

The Honeywell WU650 is a high-performance automation solution specifically engineered for demanding environments such as the power industry, petrochemical plants, and general automation systems. Renowned for its robust input/output capacity and exceptional durability, the WU650 delivers reliable, precise control and monitoring capabilities that meet the stringent requirements of modern industrial applications.

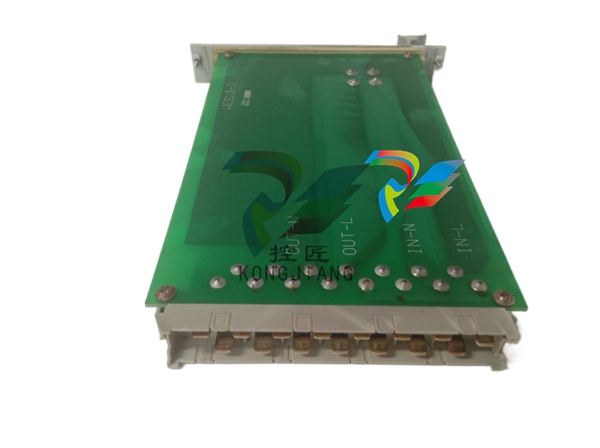

Designed with versatility and resilience in mind, the Honeywell WU650 supports a wide range of input/output configurations, enabling seamless integration with various sensors, actuators, and control devices commonly found in complex automation setups. Its input channels are capable of handling both analog and digital signals with high accuracy, while the output modules provide fast and stable response times, ensuring real-time process control. The unit’s rugged construction allows it to operate reliably in harsh conditions, including extreme temperatures, vibration, and exposure to corrosive substances frequently encountered in petrochemical and power generation environments.

Performance-wise, the WU650 boasts advanced signal processing capabilities and low latency communication protocols, which significantly enhance system responsiveness and efficiency. Its compatibility with Honeywell’s proprietary control networks and open industrial standards facilitates easy integration into existing automation architectures, reducing downtime and installation costs. In testing scenarios, the WU650 consistently demonstrates superior noise immunity and minimal signal drift, key indicators of its engineering excellence.

In practical applications, the Honeywell WU650 excels in scenarios requiring precise measurement and control under challenging conditions. For instance, in power generation plants, it manages turbine controls and generator monitoring with unparalleled accuracy, contributing to optimized energy output and safety compliance. Within petrochemical facilities, the WU650’s reliable performance ensures continuous monitoring of critical process variables such as temperature, pressure, and flow rates, helping prevent costly shutdowns and enhancing workplace safety. In general automation, its flexibility and robust design make it an ideal choice for manufacturing lines, water treatment plants, and HVAC systems that demand consistent, automated oversight.

When compared to other Honeywell models, the WU650 stands out due to its balanced combination of scalability, durability, and advanced functionality. While models like the Honeywell PX65A and Honeywell 50086421-003 offer specialized capabilities in pressure sensing and industrial control respectively, the WU650 provides a more comprehensive solution that integrates multiple signal types and supports higher channel density. Unlike the Honeywell DC2501-0E-0000-100-00000-EC-0, which focuses primarily on digital output control, the WU650 manages both analog and digital interfaces with equal proficiency. Additionally, it surpasses the Honeywell 086211-00 and Honeywell 51304584-200 in environmental tolerance, making it better suited for extreme industrial conditions.

Alongside the Honeywell WU650, we also offer complementary products such as the Honeywell WI660 and Honeywell XF522-A, which extend the system’s capabilities in wireless integration and high-precision flow measurement respectively. Other related models include the Honeywell 51305508-200 and Honeywell 51401583-200, which serve as specialized input/output modules that can enhance the functionality of a WU650-based control system. For applications requiring advanced process visualization and control, the Honeywell STD830-E1HS4AS-1-A-ADB-11C-B-21A0-00-0000 and Honeywell MU-FOED02 provide ideal human-machine interface and network interface solutions. Additionally, the Honeywell CC-PSV201 and Honeywell AD650 offer supplementary protection and diagnostic features compatible with WU650 installations.

The application of the Honeywell WU650 in the power industry, petrochemical, and general automation sectors highlights Honeywell’s commitment to delivering automation products that combine reliability, precision, and adaptability. Its proven track record in these industries is supported by Honeywell’s extensive portfolio, which includes models such as the Honeywell PX940 for pressure monitoring and the Honeywell 2001-100-150-126-280-20-100000 for high-capacity analog control. Together, these products form a robust ecosystem that addresses a wide range of industrial automation challenges.

In summary, the Honeywell WU650 is a versatile and durable automation product engineered to meet the stringent demands of power generation, petrochemical processing, and general automation applications. Its superior input/output capacity, advanced performance metrics, and rugged design distinguish it from other Honeywell models, while its seamless integration with complementary products like the Honeywell WI660, Honeywell XF522-A, and Honeywell STD830 series ensure a comprehensive automation solution. For industries seeking reliable, high-precision control in challenging environments, the Honeywell WU650 represents a trusted choice backed by Honeywell’s legacy of engineering excellence.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|