The Allen-Bradley SLC 500 series of Programmable Logic Controllers (PLCs) is a highly regarded and widely used solution in the industrial automation landscape. **General Overview** The SLC 500 PLCs are designed to provide robust control capabilities for a diverse range of industrial applications. They are known for their reliability, flexibility, and ease of use, making them a popular choice among industrial engineers and technicians.

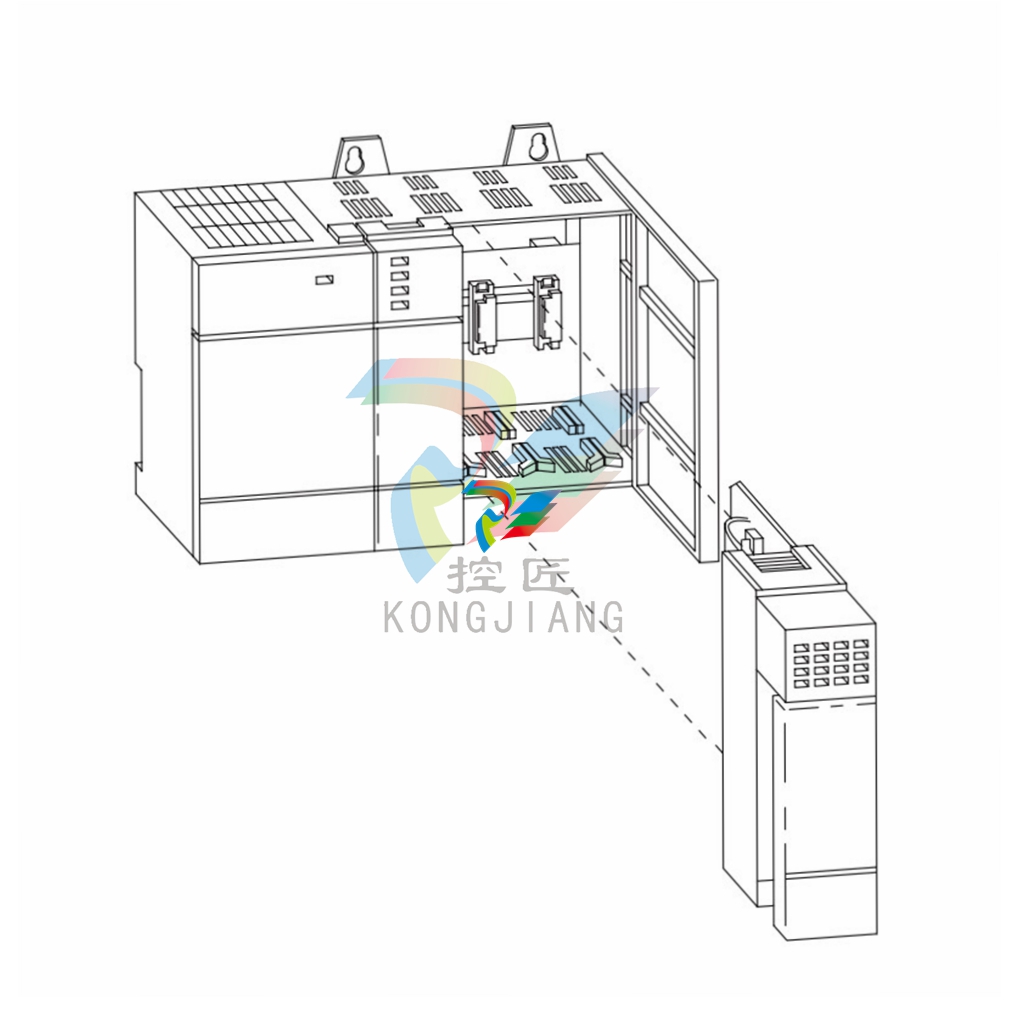

**Hardware Architecture** These PLCs feature a modular design, allowing for easy customization and expansion. The base unit provides the core processing power and communication interfaces. It can be augmented with various input and output modules, such as digital and analog modules, to adapt to different application requirements. The modular nature enables users to precisely configure the PLC system according to the specific needs of their industrial processes, whether it's a small-scale manufacturing setup or a large industrial plant. **Programming Capabilities** The SLC 500 series supports multiple programming languages, including Ladder Logic, which is a popular and intuitive choice for many industrial programmers. This allows for straightforward implementation of control logic, making it accessible even to those with moderate programming skills. Additionally, other languages like Structured Text and Function Block Diagram can also be utilized, providing more flexibility for complex programming tasks. The ability to switch between languages based on the task at hand gives programmers a powerful toolset to create efficient and effective control programs. **Communication Features** Effective communication is crucial in industrial automation, and the SLC 500 PLCs do not disappoint. They offer a range of communication options, such as Ethernet, serial ports, and DeviceNet. These communication interfaces enable the PLC to interact with other devices in the industrial network, including human-machine interfaces (HMIs), other PLCs, and various sensors and actuators. This seamless communication allows for real-time data exchange, facilitating coordinated control and monitoring of the industrial processes. **Reliability and Durability** Built to withstand the rigors of industrial environments, the SLC 500 PLCs are highly reliable. They are engineered with quality components and have robust casing to protect against dust, moisture, temperature fluctuations, and electrical interference. This durability ensures that the PLCs can operate continuously for extended periods without significant failures, minimizing downtime and maximizing productivity in industrial operations. **Applications** The Allen-Bradley SLC 500 PLCs find wide application in numerous industries. In manufacturing, they are used to control production lines, manage machine operations, and coordinate material handling systems. In the energy sector, they can be used to monitor and control power generation and distribution processes. In the automotive industry, they play a role in robotic assembly and quality control operations. In conclusion, the Allen-Bradley SLC 500 PLCs offer a comprehensive set of features, including modular design, versatile programming capabilities, effective communication options, and high reliability. These qualities make them an invaluable asset in various industrial applications, enabling efficient control and monitoring of industrial processes.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|