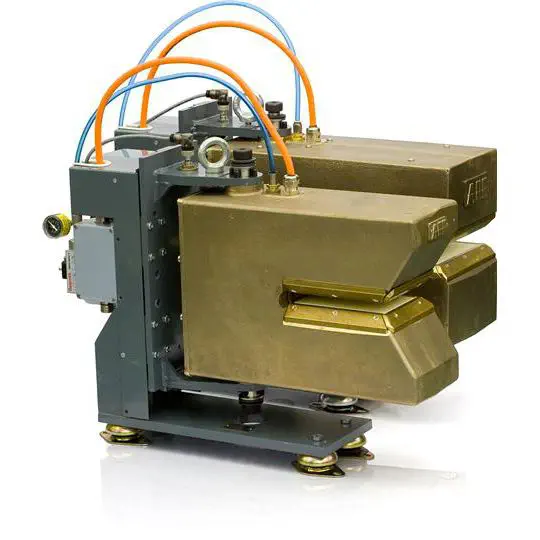

Contact-free measurement and a robust design makes The Millmate Thickness Gauge a thickness gauge that will provide high availability and hassle-free operation in harsh industrial environment. The gauge has no fragile parts or parts that will age. Therefore the MTG provides a superior long-term stability. From a maintenance point of view the system is the most dependable thickness gauge on the market. An aluminium-bronze housing is used as a case for the measuring coils and the electronics. The measured thickness deviation and other signals from the gauge are transferred to a control unit via fieldbus communication. Only a few certified plates (included in delivery) are needed to calibrate the system to cover the complete measuring range. After calibration at commissioning, the system measures any non-ferrous material or alloy without additional calibration.

The heavy-duty design of the gauge and the stability of the measuring principle makes the Millmate Thickness Gauging System superior in applications that previously were considered impossible. Measurement can be done close to the rollgap, without removal of emulsion. Material The MTG is designed for dependapble gauge measurement on a wide range of non-ferrous materials with different alloy compositions and resistivities, i.e. aluminium, copper, zinc, tin, lead and beryllium. Single or Double gauge system In reversing mills it is very common to use thickness gauges on both sides of the mill. The MTG system offers two different contol units, one for handling a single gauge and the other for handling two gauges.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|