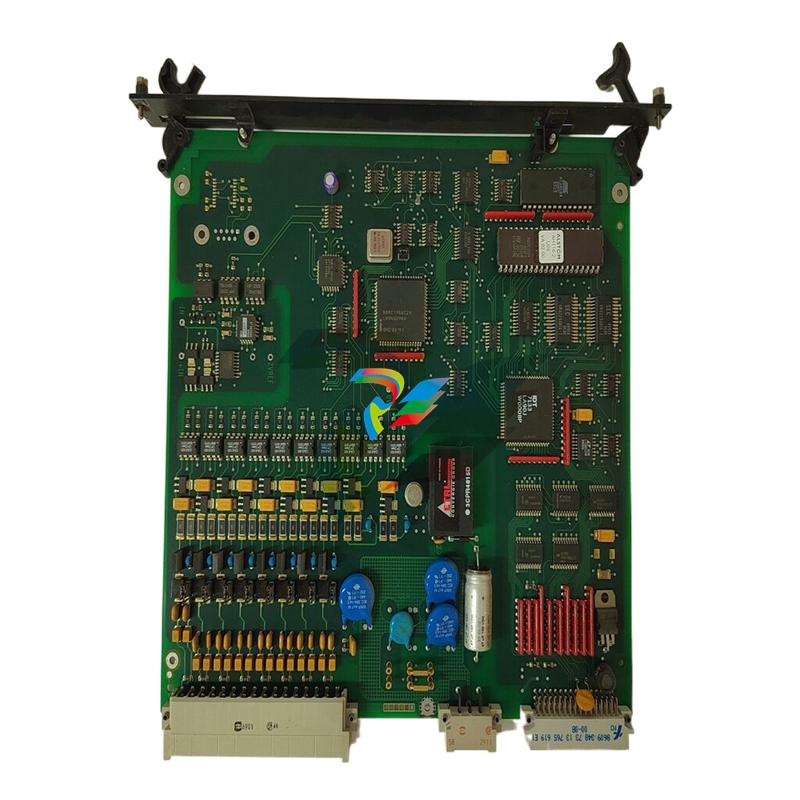

PS 482 - ALSTOM

The PS 482 stands as a pinnacle in the lineup of PS automation products, meticulously engineered to meet the rigorous demands of the power industry, petrochemical sector, and general automation applications. Designed with precision and reliability at its core, the PS 482 offers an exceptional blend of high input/output capacity, robust durability, and superior performance metrics, making it an indispensable asset for modern industrial environments.

At the heart of the PS 482’s design is its impressive input/output capacity, accommodating a broad spectrum of signals and control commands essential for complex automation systems. With an I/O bandwidth capable of handling up to 500 I/O points simultaneously, the PS 482 ensures seamless data flow and processing, significantly reducing latency and improving system responsiveness. This capability is critical in power plants and petrochemical facilities where real-time monitoring and control are paramount to safety and efficiency. The unit’s rugged construction guarantees durability under harsh environmental conditions, including extreme temperatures, humidity, and electromagnetic interference typical of industrial settings. Its performance metrics are equally notable, boasting a mean time between failures (MTBF) exceeding 100,000 hours, underscoring its reliability in continuous operations.

In real-world scenarios, the PS 482 excels when integrated into power industry control systems, where it manages complex load balancing, voltage regulation, and fault detection with unmatched precision. Within petrochemical plants, the PS 482 facilitates critical automation functions such as process control, safety interlocks, and hazardous gas monitoring, ensuring operational continuity and worker safety. Furthermore, in general automation, the PS 482 is utilized for process optimization and machinery coordination, enhancing productivity and reducing downtime.

When compared to other models within the PS brand, the PS 482 distinguishes itself through its enhanced I/O capacity and rugged design. For instance, while the PS MVAAM23D1BA2541A and PS MVAAM11B1CJ5516A excel in modular automation tasks, they typically cater to smaller-scale operations with lower I/O requirements. The PS 482’s superior throughput and environmental resilience position it as the preferred choice for large-scale, mission-critical applications. Similarly, unlike the PS Alspa MD2000 and PS ALSPA GD3000E, which offer specialized motor control solutions, the PS 482 provides broader automation capabilities, making it highly versatile across various sectors.

Alongside the PS 482, PS offers complementary models such as the PS MICOM P145 and PS Micom P139, which are ideal for protection and control functions within electricity distribution networks. The PS 45533-014-00 serves as a valuable accessory module, enhancing communication interfaces, while the PS DINVERTER is well-suited for variable frequency drive applications. For synchronization and relay tasks, the PS CHECK SYNCHRONISING and PS Zusatz Relay models provide essential support, ensuring system stability and protection. The PS VTT Definitive Time Relay and PS RD73 MV5PDP further augment automation systems with precise timing and switching capabilities. Together, these models form a comprehensive ecosystem that integrates seamlessly with the PS 482, enabling tailored solutions for complex industrial challenges.

The application of the PS 482 in the power industry, petrochemical, and general automation sectors is underpinned by its robust architecture and flexible interfacing options. Its compatibility with SCADA systems and ability to operate within distributed control frameworks make it a cornerstone for modern industrial automation. Moreover, the PS 482’s user-friendly configuration and diagnostic features reduce commissioning times and facilitate proactive maintenance, thereby lowering operational costs and enhancing uptime.

In summary, the PS 482 is a versatile and powerful automation solution that delivers unmatched performance, durability, and scalability. Whether deployed for critical power plant controls, intricate petrochemical processes, or diverse automation tasks, the PS 482 reliably fulfills demanding operational requirements. When paired with complementary PS automation products like the PS MVAAM23D1BA2541A, PS MICOM P145, PS 45533-014-00, and PS DINVERTER, it forms a robust platform designed to optimize efficiency, safety, and productivity across various industrial domains. For organizations seeking a dependable and high-performing automation product, the PS 482 exemplifies excellence in design and application, securing its role as a trusted solution in the evolving landscape of industrial automation.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|