DCS; Industrial control system

Product

Article

NameDescriptionContent

Argument

Current Location:

PRODUCT SHOW

Description

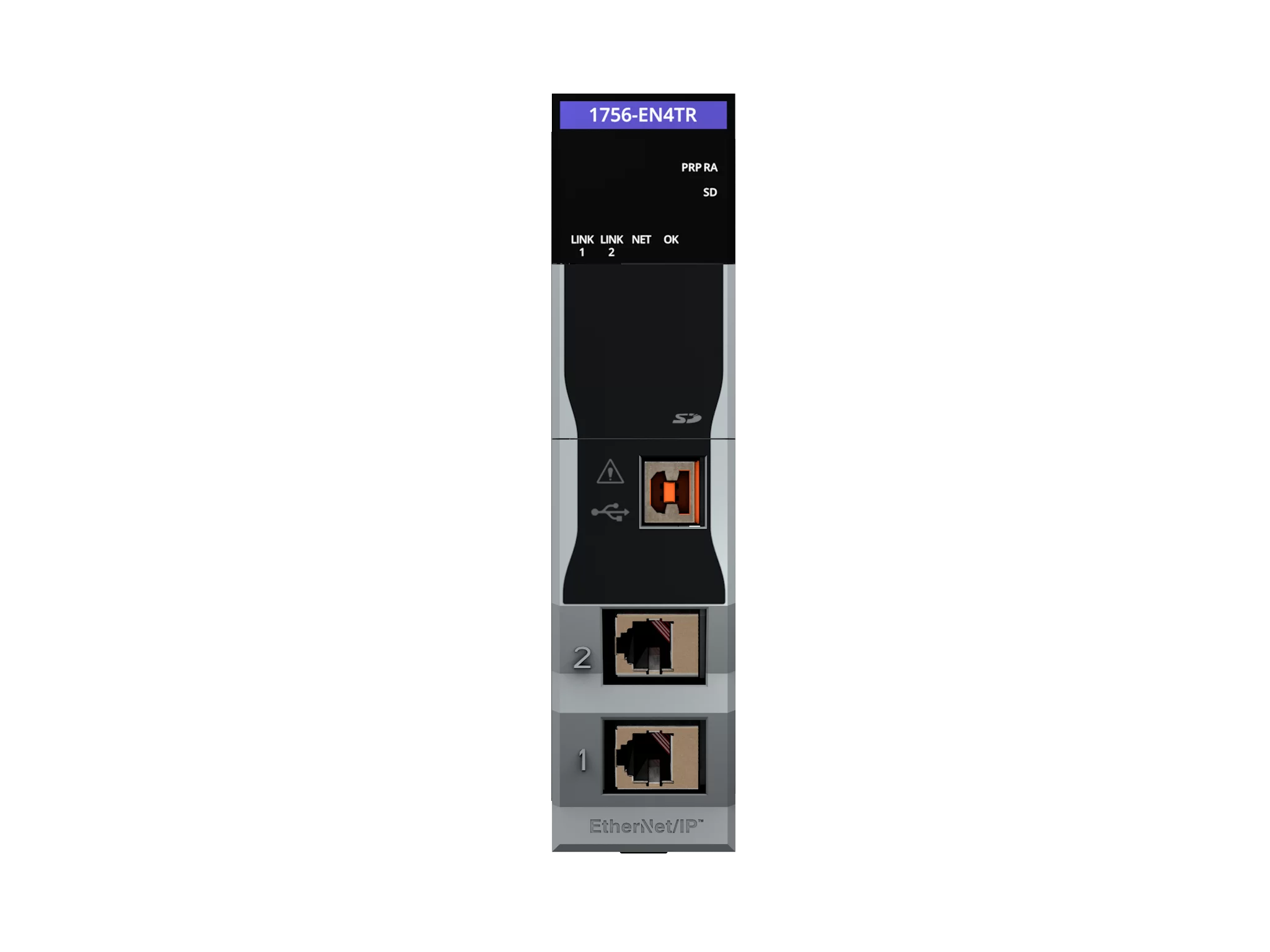

1756-EN4TR Front (Model with a Specific Reference of 2048)

The 1756-EN4TR Front, often associated with the reference number 2048, is a significant component within the realm of industrial automation and control systems. Here is a detailed description of its various aspects:

1. Physical Design and Construction

- Size and Appearance: It has a specific form factor designed to fit into standard industrial control racks or enclosures. While the exact dimensions might vary depending on its specific configuration, it is engineered to be compatible with other components in the 1756 series. The front panel has a clean and organized layout, with clearly visible indicators, ports, and connection points that are easy to access and identify.

- Housing Material: The housing of the 1756-EN4TR Front is typically made from high-quality, durable materials. It is usually constructed from robust plastic or metal alloys that can withstand the rigors of industrial environments, including exposure to dust, temperature variations, vibration, and electromagnetic interference. This sturdy construction ensures its long-term reliability and protects the internal electronic components from potential damage.

- Mounting Arrangement: It is designed for easy and secure mounting within an industrial control system. It may feature screw holes or mounting brackets on the sides or back, allowing it to be firmly attached to a DIN rail or a dedicated mounting panel. The mounting process is straightforward, enabling technicians to install it quickly and accurately during system setup or upgrades.

2. Connectivity Options

- Ethernet Ports: One of the key features of the 1756-EN4TR Front is its multiple Ethernet ports. These ports are usually compliant with industry-standard Ethernet protocols such as 10/100/1000Base-T, enabling high-speed and reliable network communication. They allow the device to connect to other components within the same local area network (LAN), such as programmable logic controllers (PLCs), human-machine interfaces (HMIs), and other networked devices. The Ethernet connectivity is crucial for data transfer, enabling real-time monitoring, control, and communication between different parts of an industrial automation system.

- Serial Ports: In addition to Ethernet ports, it may also incorporate serial ports, such as RS-232 or RS-485 interfaces. These serial ports provide alternative means of communication, especially useful for connecting to legacy equipment or devices that rely on serial communication protocols. They can be used for tasks like configuring specific parameters of connected devices, receiving data from sensors with serial output, or sending control commands to actuators that support serial input.

- Connector Types and Standards: The ports on the 1756-EN4TR Front are equipped with industry-standard connectors to ensure compatibility and reliable connections. The Ethernet ports typically use RJ45 connectors, which are widely available and easy to work with. The serial ports have connectors that match the respective serial standards, with proper pin configurations and locking mechanisms to prevent accidental disconnection during operation.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Customer Reviews

Satisfaction :

5 Stars

No evaluation information