I. Principle of Operation

It is based on Tunable Diode Laser Spectroscopy (TDLS). This technique relies on the ability of tunable diode lasers to emit light at specific wavelengths. These wavelengths are carefully selected to match the absorption lines of target gas molecules. When the laser light passes through the gas sample, the gas molecules absorb the light at their characteristic wavelengths. By precisely measuring the amount of light absorption, the spectrometer can accurately determine the concentration of the specific gases present in the sample.

II. Technical Specifications

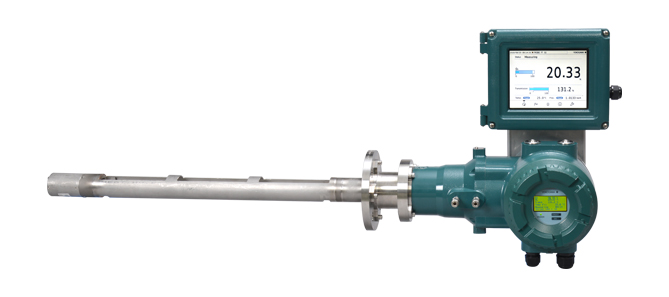

Probe Design: The probe is a key component of the TDLS8200. It is designed to be inserted directly into the process environment or the area where gas analysis is required. The probe is usually made of materials that can withstand harsh conditions such as high temperatures, pressures, and corrosive atmospheres. It has a compact and robust structure to ensure stable operation in various industrial settings.

Detection Capability: It has a wide range of detectable gases. It can accurately measure common industrial gases like carbon monoxide (CO), carbon dioxide (CO₂), hydrogen (H₂), oxygen (O₂), methane (CH₄), and many others. The detection limits can reach extremely low levels, often in the parts per million (ppm) or even parts per billion (ppb) range for some trace gases, depending on the specific configuration and calibration.

Accuracy and Precision: The TDLS8200 offers high measurement accuracy. Generally, the accuracy can be within a few percent of the actual gas concentration under proper calibration and stable operating conditions. The precision of repeated measurements is also excellent, ensuring consistent and reliable results over time. The spectrometer is equipped with advanced calibration algorithms and internal reference systems to maintain this high level of accuracy and precision.

Response Time: It has a relatively fast response time, typically on the order of seconds or even less in some cases. This enables it to quickly detect changes in gas concentrations, which is crucial for real-time monitoring and timely response in industrial processes or environmental monitoring applications.

III. Applications

Industrial Applications: In the petrochemical industry, it can be used to monitor gas compositions in refinery processes, such as in catalytic crackers or distillation columns, to ensure the quality of products and the safety of operations. In the power generation sector, it helps in monitoring combustion gases in boilers and turbines to optimize fuel efficiency and reduce emissions. In the steel industry, it is employed to measure gas concentrations in blast furnaces and other metallurgical processes.

Environmental Monitoring: For air quality monitoring, it can be installed at industrial sites, urban areas, or near pollution sources to continuously measure the levels of harmful gases like sulfur dioxide (SO₂), nitrogen oxides (NOₓ), and volatile organic compounds (VOCs). It also plays an important role in indoor air quality monitoring in buildings, factories, and laboratories to ensure a healthy living and working environment.

Research and Development: In scientific research, it is widely used in fields like gas chemistry, environmental science, and materials research. For example, in studying chemical reactions involving gases, it can provide real-time data on gas concentrations to help researchers understand reaction kinetics and mechanisms.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|