DCS; Industrial control system

Product

Article

NameDescriptionContent

Argument

Current Location:

PRODUCT SHOW

Description

Emonitor Condition Monitoring Software: A Detailed Description

1. Introduction

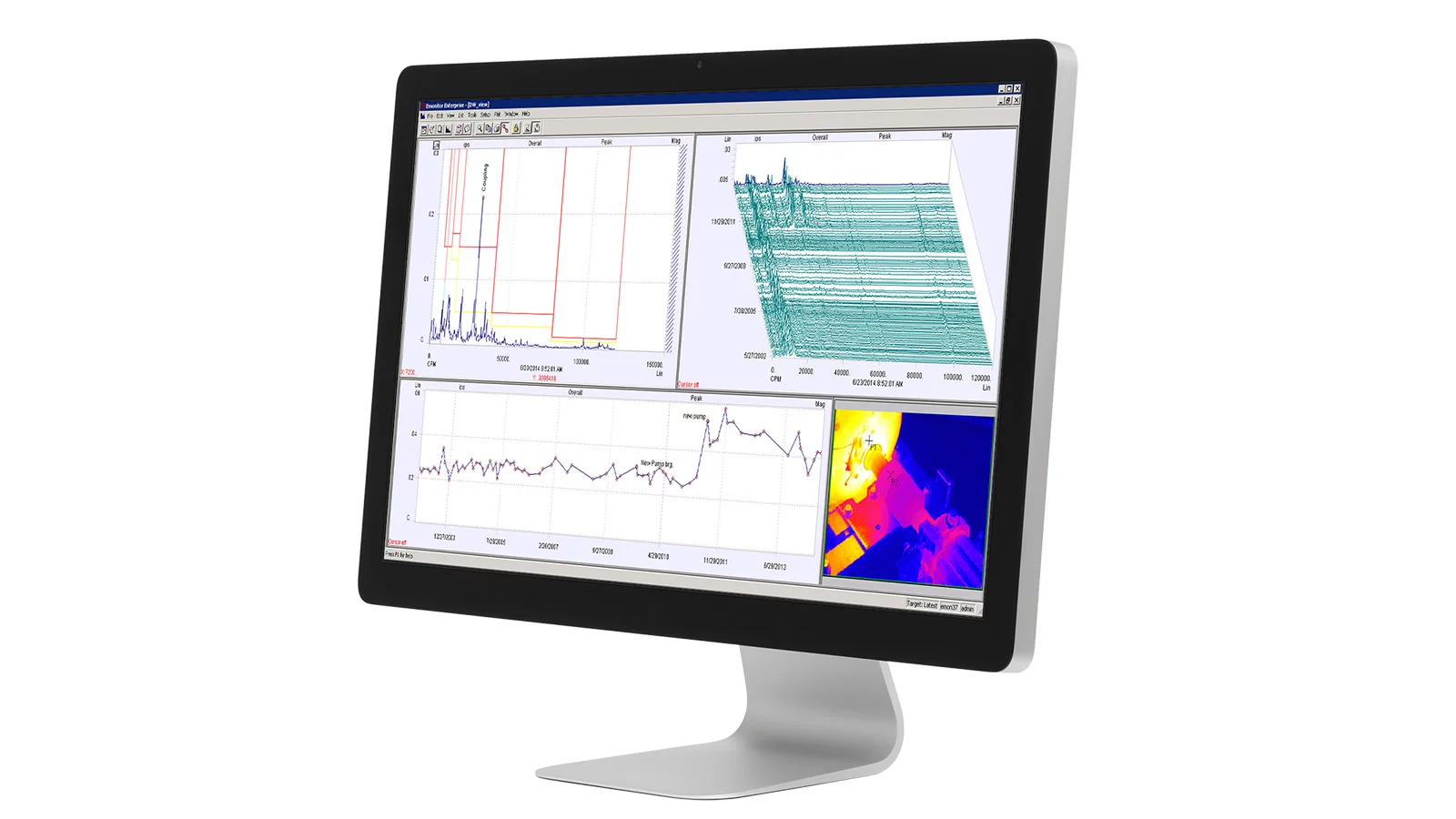

Emonitor Condition Monitoring Software is a sophisticated and highly functional software solution designed specifically for monitoring the condition of various industrial assets and equipment. It plays a crucial role in predictive maintenance strategies, enabling businesses to optimize the performance, reliability, and lifespan of their machinery and systems while minimizing unexpected downtime and reducing maintenance costs.

2. User Interface and Usability

- Intuitive Design: The software features an intuitive user interface that is designed to be user-friendly even for those with limited technical expertise. It presents information in a clear and organized manner, typically using graphical dashboards, charts, and tables to display key data. This allows operators, maintenance technicians, and engineers to quickly access and understand the current status of the monitored equipment at a glance.

- Customization Options: Emonitor offers extensive customization capabilities. Users can tailor the interface according to their specific needs and preferences. For example, they can choose which parameters and data points to display prominently, set up personalized alert thresholds, and configure the layout of the dashboards to focus on the most critical aspects of their equipment or processes.

- Navigation and Accessibility: The software has a well-structured navigation system that makes it easy to move between different sections, such as viewing real-time data, historical trends, or diagnostic reports. It also ensures that relevant information is accessible with just a few clicks, whether it's looking at the condition of a single piece of equipment or getting an overview of an entire production line or facility.

3. Data Acquisition and Integration

- Multi-source Data Collection: Emonitor is capable of collecting data from a wide variety of sources. It can interface with different types of sensors, including vibration sensors, temperature sensors, pressure sensors, and more, which are commonly installed on industrial equipment. Additionally, it can integrate with existing automation systems, programmable logic controllers (PLCs), and other data-generating devices in the industrial environment. This enables it to gather a comprehensive set of data that reflects the actual operating conditions of the assets.

- Data Format Compatibility: The software supports multiple data formats, ensuring seamless integration with different sensor technologies and systems. It can handle both analog and digital data inputs, adapting to the specific communication protocols used by various devices. This flexibility allows for easy connection to legacy equipment as well as the latest sensor models, facilitating a smooth data flow into the monitoring system.

- Real-time and Historical Data Handling: It not only captures real-time data but also stores historical data for in-depth analysis. The real-time data enables immediate awareness of any changes or anomalies in the equipment's condition, while the historical data is invaluable for identifying trends, patterns, and long-term performance characteristics. This historical record can be used to predict future maintenance needs and understand how the equipment has behaved under different operating conditions over time.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Customer Reviews

Satisfaction :

5 Stars

No evaluation information