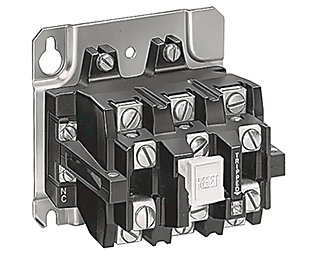

-### Introduction to NEMA Eutectic Alloy Overload Relays NEMA Eutectic Alloy Overload Relays are crucial components in electrical systems, specifically engineered to safeguard motors and associated equipment from the harmful effects of overload conditions. They play a significant role in various industrial, commercial, and even some residential applications where motor-driven machinery is in use. ### Design and Construction These relays feature a unique design centered around the use of eutectic alloy elements. The housing is typically made from durable materials that can withstand the rigors of industrial environments, such as robust metals or high-quality engineering plastics. It provides protection against dust, moisture, and mechanical impacts, ensuring the internal components remain in good working condition. The core component is the eutectic alloy element itself. This alloy is carefully selected for its specific thermal properties. It is usually housed within a bimetallic strip or a similar structure. When current flows through the relay and the connected motor circuit, the heat generated by the electrical current causes the eutectic alloy to react. As the temperature rises due to an overload situation in the motor, the eutectic alloy melts or undergoes a significant phase change at a precisely calibrated temperature point.

The relay also incorporates mechanical linkages and contacts. The mechanical components are designed to work in harmony with the thermal behavior of the eutectic alloy. When the alloy responds to the excessive heat, it triggers the movement of the mechanical linkages, which in turn opens or closes the electrical contacts within the relay. These contacts are made from materials with good electrical conductivity and wear resistance to ensure reliable operation over multiple cycles of opening and closing. ### Functional Capabilities The primary function of NEMA Eutectic Alloy Overload Relays is to protect motors from overloads. In normal operating conditions, when the motor is drawing current within its rated capacity, the relay remains in its normal state, allowing the electrical circuit to remain closed and power to flow to the motor. However, when an overload occurs, such as when the motor is forced to operate under excessive mechanical load or there is a problem in the motor's winding that causes it to draw too much current, the heat generated increases. As the temperature reaches the preset threshold of the eutectic alloy, the alloy's change in state causes the relay to trip. When the relay trips, it opens the contacts in the motor circuit, interrupting the power supply to the motor. This immediate action prevents the motor from overheating and suffering damage to its windings, bearings, or other critical components. Moreover, some models of these relays may offer adjustable settings. This allows users to calibrate the overload protection level according to the specific requirements of the motor being protected. For example, different types of motors with varying power ratings and operating characteristics may need different temperature thresholds for optimal protection, and the adjustable feature enables this customization. ### Application Areas In industrial manufacturing plants, these relays are widely used to protect motors in machinery like conveyor belts, machine tools, and pumps. For instance, in a factory where conveyor belts are constantly in operation to transport materials, if a jam occurs and causes the motor driving the conveyor to overload, the NEMA Eutectic Alloy Overload Relay will detect the excessive heat and cut off the power to prevent the motor from burning out. In commercial settings such as shopping malls or office buildings, they are employed to safeguard motors in air conditioning units, elevators, and ventilation systems. In an office building's air conditioning system, if the compressor motor experiences an overload due to a blocked air filter or other issues, the relay will act to protect the motor and maintain the overall reliability of the system. They can also be found in some residential applications, like in garage door openers or pool pumps, where motors need protection from potential overload situations that could occur during normal usage. ### Advantages One of the main advantages of NEMA Eutectic Alloy Overload Relays is their simplicity and reliability. Their thermal-based operation directly responds to the actual heat generated in the motor circuit, providing a straightforward and effective means of overload protection. The use of eutectic alloy ensures a consistent and predictable response to temperature changes, reducing the risk of false tripping or failure to trip when needed. The adjustable settings make them adaptable to a wide variety of motor types and applications, enhancing their versatility. Additionally, their durable construction means they can withstand the harsh conditions often found in industrial and commercial environments, contributing to their long service life and reducing the need for frequent replacements. In conclusion, NEMA Eutectic Alloy Overload Relays are essential devices in electrical systems for protecting motors, offering a combination of reliable design, functional effectiveness, and wide application areas that contribute to the safety and longevity of motor-driven equipment.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|