DeltaV InSight’s On-Demand Tuning is available for PID and Fuzzy Logic control blocks in the DeltaV controller or

Emerson FOUNDATION Fieldbus devices.

Tuning recommendations are available on demand by initiating automatic testing of the process.

During the tests, the loop remains under control to prevent large disturbances to the process.

The on-demand tuning method is based on the Åström-Hägglund algorithm referred to as the relay-oscillation method.

Users may easily adjust the desired speed of response for the control loop to speed up or slow down the closed loop response.

Advanced users may also specify optional tuning rules for modified Ziegler-Nichols, Lambda, or Internal Model Control.

Easily identify underperforming control loops. Do you know how well your control loops are performing?

Why fly blind when you can continuously monitor control performance and identify the best areas to focus resources for maximum plant efficiency?

With DeltaV InSight, you can quickly identify abnormal control conditions such as wrong control mode, limited output,

and high variability; identify malfunctioning devices that may cause control problems; and accurately pinpoint loops that need retuning with a model-based tuning index.

Embedding DeltaV InSight into the automation system improves both ease of use and calculation performance.

InSight is easy to use because there is no additional configuration required. InSight configuration is automatic:

every time a control loop is added, deleted, or modified in the control system,

The Control Conditions monitored for every control loop and reported in the Overview and Summary displays include:

Uncertain Input. A block’s process variable is bad,uncertain, or limited.

Limited Control. A downstream condition is limiting the control block action; for example, the output is at a maximum limit.

Incorrect Mode. The actual mode of a block does not match the normal mode configured for the block.

Large Variability. A block’s standard deviation and variability index are exceeding their maximum limits.

Process Oscillation. A block’s process variable has oscillatory behavior.

Recommended Tuning. A tuning recommendation has been calculated that significantly improves control.

Device Alerts. Indicates when a control module has one or more devices that have had active device alerts.

DeltaV InSight calculates the percent time that these control conditions exist and eports them as an abnormal condition if the percent time exceeds a defined global limit.

Abnormal control conditions are indicated in overview graphs and summary tables from which the user may drill down on specific blocks for more detailed control performance indices and historical trends.

InSight configuration is automatically updated with the latest configuration.

DeltaV InSight also performs better because the control calculations are embedded directly in the controller.

Calculations for control performance, diagnostics, and tuning require a lot of information,which can significantly add to system communications loading.

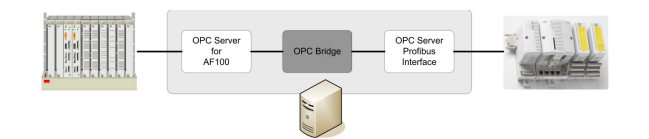

Embedded calculations greatly reduce the system communications as compared with traditional OPC data access.

Furthermore, for fast loops, it’s virtually impossible to scan the control loop via OPC fast enough for accurate calculations.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Address:Xiamen City, Fujian Province, China

TELL:

E-MAIL:gedcs868@gmail.com

.png)