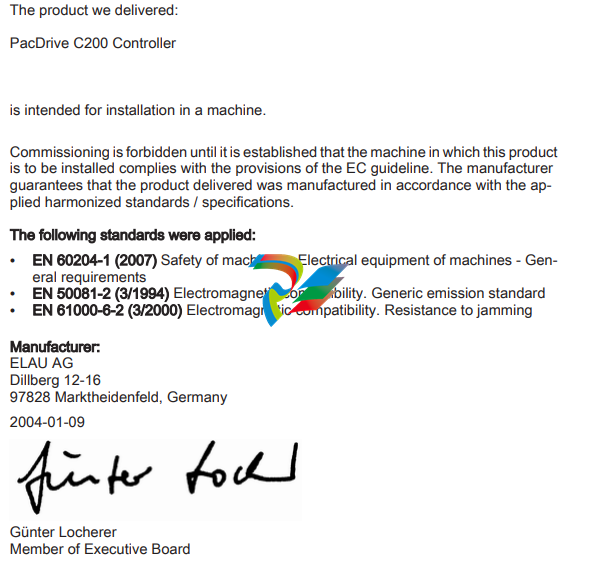

IC693MDL740E GE FANUC (ALSTOM) - Automate Programmable

The IC693MDL740E GE FANUC (ALSTOM) is a robust and versatile automation module designed to meet the stringent demands of the power industry, petrochemical, and general automation sectors. Engineered for high reliability and precision, this model offers exceptional input/output capacity combined with durable construction to ensure optimal performance in harsh industrial environments.

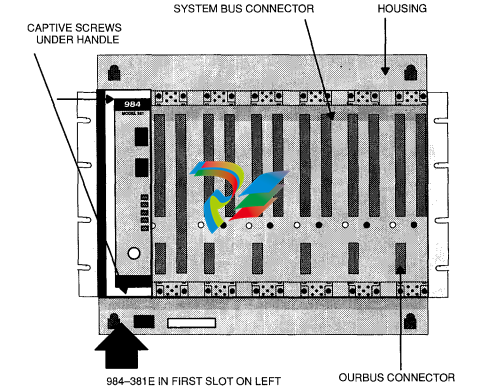

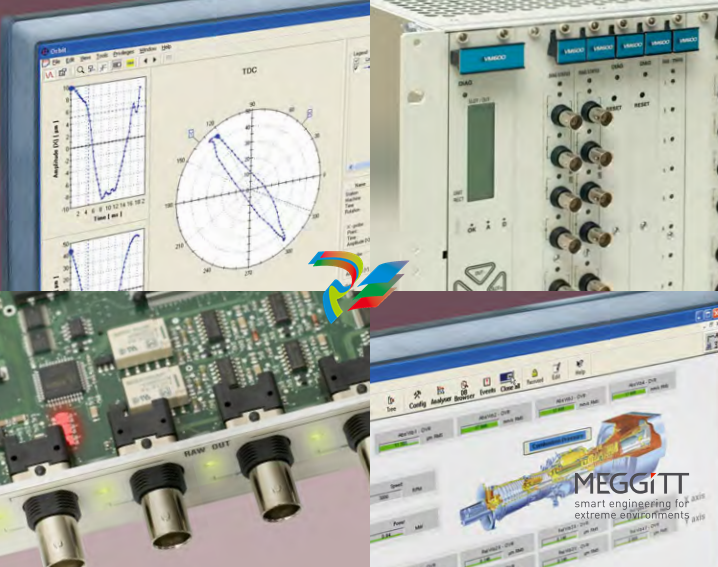

At its core, the IC693MDL740E provides extensive input/output capabilities designed to handle complex control tasks. It supports a wide range of digital and analog signals, making it suitable for diverse applications requiring precise monitoring and control. Its architecture is optimized for fast processing speeds and seamless integration within larger GE FANUC automation systems, ensuring real-time responsiveness and enhanced operational efficiency. The module’s durability is reflected in its resistance to electrical noise, temperature fluctuations, and mechanical vibrations, which are common in power plants and petrochemical facilities. This resilience guarantees consistent uptime and minimizes maintenance requirements, critical factors for industries where downtime translates into significant losses.

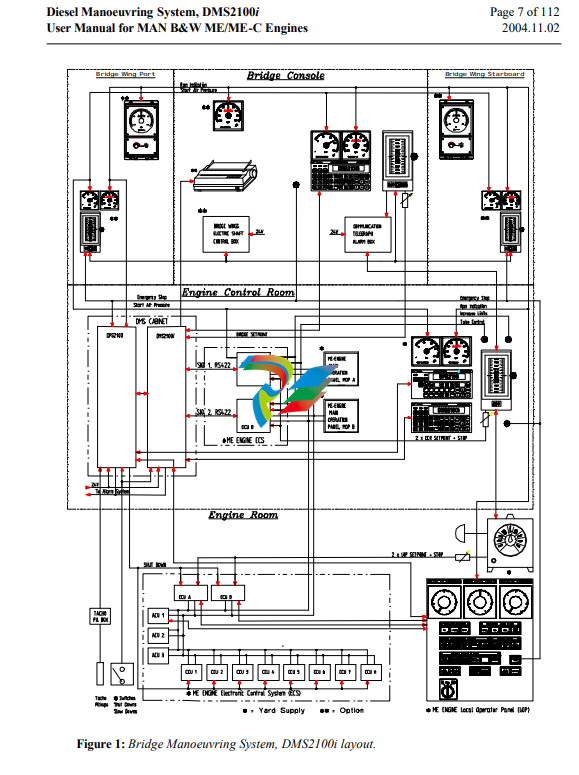

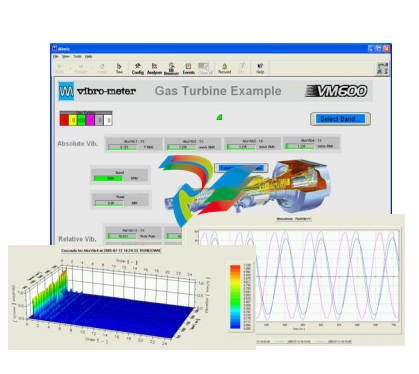

In practical usage, the IC693MDL740E excels in environments such as power generation plants, where control of turbines, generators, and auxiliary equipment demands both accuracy and reliability. Within the petrochemical industry, it effectively manages process control systems, including valve actuations, pressure regulation, and safety interlocks, ensuring smooth and safe operations. Its adaptability also extends to general automation applications, where it supports manufacturing lines, packaging systems, and material handling equipment with precise input/output management and robust communication capabilities.

When compared with other models within the GE FANUC portfolio, the IC693MDL740E stands out for its balanced combination of performance and reliability. For instance, models like the IC693MDL740E PIB102A-3BEB0180-A and IC693MDL740E 20x4496 offer specialized functionalities, yet the IC693MDL740E maintains superior versatility across multiple industrial settings. Unlike the IC693MDL740E 556421 or IC693MDL740E p141316a6m0440j, which are optimized for niche applications, the IC693MDL740E serves as a comprehensive solution capable of integrating seamlessly with complementary units such as the IC693MDL740E Alstom/Microphone P241 311a2m0600j for enhanced signal processing and the IC693MDL740E Dynamic Positioning Joystick Controller Series DP for precise manual control inputs.

Furthermore, alongside the IC693MDL740E GE FANUC (ALSTOM), we also offer the IC693MDL740E Power Preheater and IC693MDL740E Power Grinding Roll Lock Nut, which complement the automation framework by providing ancillary support in power plant operations. The IC693MDL740E MVAX21K1DD0754A and IC693MDL740E MCRI01T1CD0751C are additional models that enhance system performance by providing expanded input/output options and improved communication protocols, making them ideal companions for large-scale automation projects.

The IC693MDL740E automation products are designed with a focus on scalability, allowing integration into complex control architectures without compromising system responsiveness. Its compatibility with other GE FANUC models such as IC693MDL740E SKIIP2013GB172-4DK0197 and IC693MDL740E 20X4284/20A ensures that users can build tailored solutions that meet specific industrial requirements. This modularity is particularly beneficial in petrochemical plants where customization and incremental upgrades are often necessary to adapt to evolving process demands.

In summary, the IC693MDL740E GE FANUC (ALSTOM) offers an unmatched combination of input/output capacity, durability, and performance, making it an essential component for applications in the power industry, petrochemical sector, and general automation fields. Its robust design and flexible integration capabilities position it as a preferred choice among automation professionals seeking reliable and scalable solutions. When paired with other models from the GE FANUC range, such as the IC693MDL740E 251-1, IC693MDL740E R200PL5490/14, and IC693MDL740E MVAX21K1DD0754A, users benefit from an integrated and highly efficient automation ecosystem optimized for demanding industrial environments.

By choosing the IC693MDL740E GE FANUC (ALSTOM), businesses gain access to a proven automation product that enhances operational efficiency, reduces downtime, and supports complex control strategies essential for modern industrial applications. It remains a cornerstone in the application of GE FANUC (ALSTOM) technology across power generation, petrochemical processing, and broader automation initiatives worldwide.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

.png)