Alstom SCN804D Medida - Interfaz M¨®dulo SCN604A

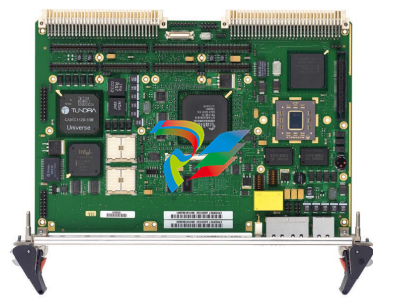

The Alstom SCN804D Medida stands out as a robust and versatile automation product designed to meet the stringent demands of the power industry, petrochemical plants, and general automation sectors. Engineered with precision, this model offers exceptional input/output capacity, durability, and performance metrics that place it at the forefront of Alstom’s extensive lineup of automation solutions.

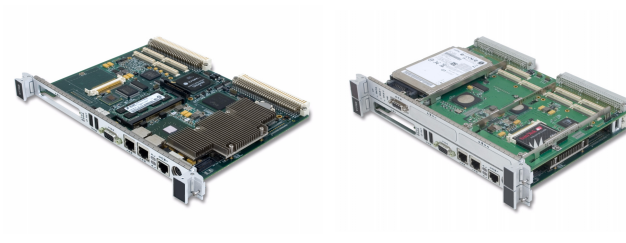

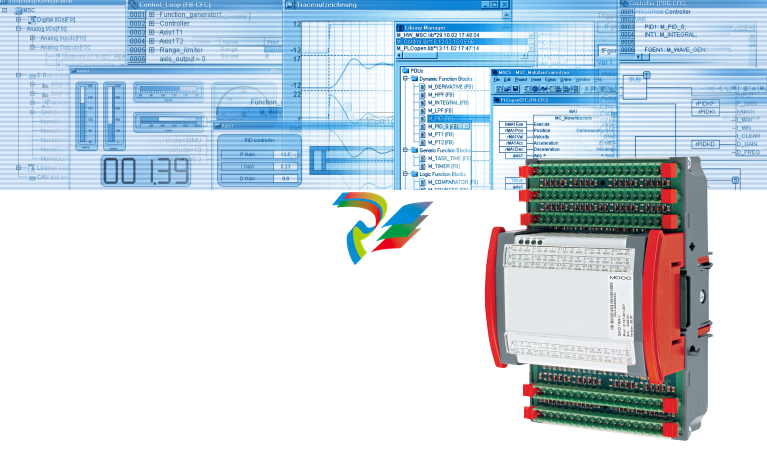

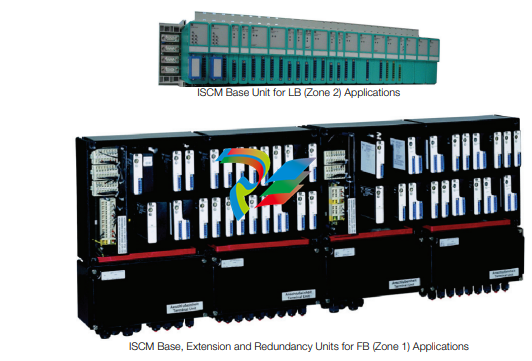

At its core, the Alstom SCN804D Medida features advanced processing capabilities that support high-speed data acquisition and control processes. Its input/output (I/O) capacity is tailored to handle complex automation tasks, accommodating multiple analog and digital signals simultaneously. This ensures seamless integration with various sensors, actuators, and control elements common in power generation and petrochemical environments. The device’s architecture supports real-time monitoring and control, providing operators with precise and reliable data essential for optimizing plant operations.

Durability is a hallmark of the SCN804D Medida, designed to withstand harsh industrial conditions such as extreme temperatures, vibrations, and electrical noise typical in power plants and chemical processing facilities. The rugged build ensures long-term operational stability, reducing downtime and maintenance costs. Moreover, its performance metrics include fast response times and high accuracy in signal processing, which are critical for maintaining process safety and efficiency. The SCN804D Medida’s compatibility with industry-standard communication protocols further enhances its adaptability across a wide range of automation systems.

In real-world applications, the Alstom SCN804D Medida excels in scenarios where precision and dependability are paramount. In the power industry, it is frequently employed for turbine control, generator monitoring, and grid synchronization tasks, ensuring optimal power output and system stability. In petrochemical plants, the device manages complex process variables such as temperature, pressure, and flow rates, contributing to safer and more efficient chemical production. Its flexibility also makes it an ideal choice for general automation projects requiring reliable interface and control solutions, including factory automation and infrastructure management.

When compared to other models within the Alstom portfolio, the SCN804D Medida offers distinct advantages. For instance, while models like the Alstom digital and Alstom Operator Interface provide excellent visualization and basic control functions, the SCN804D Medida delivers enhanced I/O capacity and ruggedness suitable for more demanding industrial environments. Compared to the Alstom Power HTGD333350P0049 and Alstom RTS-61, which are specialized for turbine and generator protection respectively, the SCN804D Medida offers a broader application scope with its versatile control and measurement capabilities. It also complements the Alstom Microverter D 3.4/500, a device focused on power conversion, by providing superior control and monitoring functions within integrated automation systems.

Alongside the Alstom SCN804D Medida, Alstom offers several related models that complement its functionality. The Alstom 20x4373/10b and Alstom Alstom/Micon enhance communication and interface capabilities, while the Alstom Combustion Engineering Grinding Roller Locking Nut supports mechanical stability in combustion systems. The Alstom Dynamic Positioning Joystick Controller Series DP and Alstom B&R Alstom provide specialized control interfaces, beneficial in marine and industrial automation contexts. Furthermore, the Alstom Fan Wheel Shaft and Alstom Power Grinding Roll Lock Nut are critical components for mechanical reliability in rotating equipment, which often integrates with the SCN804D Medida’s control systems. For enhanced system synchronization, the Alstom CHECK SYNCHRONISING unit pairs well with the SCN804D Medida’s monitoring capabilities, ensuring optimal operational timing. Lastly, the Alstom BLUELINE series represents an advanced range of automation products that can be integrated to expand system functionality.

The application of SCN804D Medida in power industry, petrochemical, and general automation settings underscores its versatility and robustness. Its ability to handle complex signal processing with high reliability makes it indispensable for operators aiming to maximize efficiency and safety. As part of the broader Alstom automation products suite, the SCN804D Medida not only delivers superior performance but also integrates seamlessly with other Alstom technologies, creating a comprehensive solution tailored to the evolving needs of industrial automation.

In summary, the Alstom SCN804D Medida is a high-performance automation device engineered for challenging industrial environments. Its superior input/output capacity, durability, and real-time processing capabilities make it a preferred choice in the power, petrochemical, and general automation sectors. When paired with complementary Alstom models such as the Alstom digital, Alstom Operator Interface, and Alstom Microverter D 3.4/500, it forms a powerful automation ecosystem that drives operational excellence and innovation.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

.png)