DCS; Industrial control system

Product

Article

NameDescriptionContent

Argument

Current Location:

PRODUCT SHOW

Description

**GE 531X111PSHATG1: A Premier Solution for Power, Petrochemical, and Automation Industries**

GE 531X111PSHATG1 - Spare Parts

GE 531X111PSHATG1 - Spare Parts

**GE 531X111PSHATG1: A Premier Solution for Power, Petrochemical, and Automation Industries**

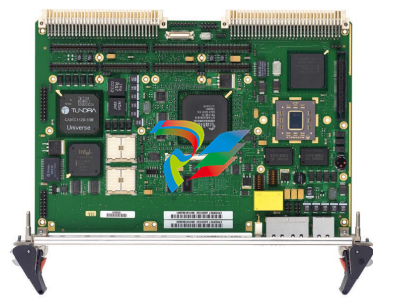

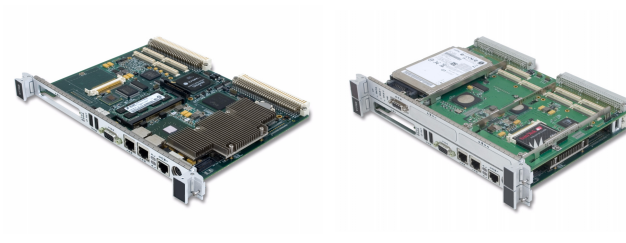

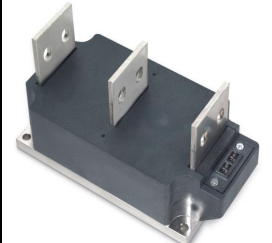

The GE 531X111PSHATG1 is a cutting-edge control board designed to meet the rigorous demands of the power industry, petrochemical sector, and general automation applications. This model showcases a range of unique technical features that set it apart in performance and reliability. With its robust input/output capacity, the GE 531X111PSHATG1 excels in managing complex control tasks, ensuring that systems operate efficiently and without interruption.

**Technical Features and Performance Metrics**

The GE 531X111PSHATG1 boasts an impressive input/output capacity that supports a wide range of devices, making it ideal for diverse industrial settings. Engineered for durability, it operates effectively in extreme conditions, which is essential for environments found in petrochemical plants and power generation facilities. The board is designed to withstand fluctuations in temperature and humidity, ensuring consistent performance over time.

In terms of performance metrics, the GE 531X111PSHATG1 provides high-speed data processing and communication capabilities, enhancing operational efficiency. Its streamlined architecture minimizes latency, allowing for rapid responses to control signals. This is particularly advantageous in critical applications where timing is everything.

**Real-World Usage Scenarios**

The versatility of the GE 531X111PSHATG1 shines in various real-world scenarios. In the power industry, it is instrumental in monitoring and controlling electrical systems, ensuring that power generation and distribution operate seamlessly. For instance, its integration with GE DS200DMCBG1AKG can enhance control in turbine operations, optimizing energy production.

In the petrochemical sector, the GE 531X111PSHATG1 works effectively in process automation, managing valves and pumps to ensure efficient chemical processing. Its compatibility with GE RET670 protection relays allows for robust safety mechanisms, safeguarding against equipment failures or hazardous situations.

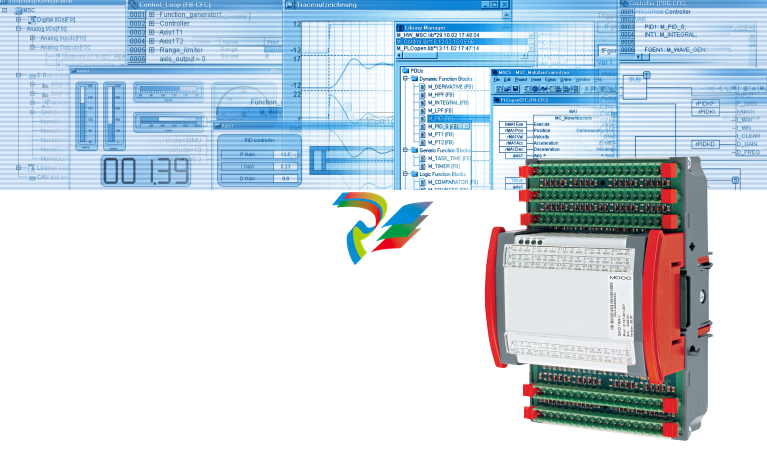

In general automation, the GE 531X111PSHATG1 facilitates sophisticated control strategies that improve production lines, making it an essential component in manufacturing settings. Its synergy with models like GE IC693MDL930LT and GE 216EA61B ensures a comprehensive automation solution that addresses both control and monitoring needs.

**Comparative Advantages**

When compared to other models in the GE lineup, such as the GE 140ACI04000 or GE 531X305NTBANG1, the GE 531X111PSHATG1 stands out due to its enhanced I/O capabilities and rugged design. While models like GE DS200TCDAF1B focus on specific applications, the versatility of the GE 531X111PSHATG1 makes it suitable for a broader range of tasks. Additionally, its integration with GE 167 PA-25SE ensures precision control in critical power applications, a feature not as prominently available in other models.

**Complementary Models**

The GE 531X111PSHATG1 is designed to complement several other GE automation products. For example, pairing it with GE IC200MDL640K allows for expanded I/O configurations, enabling more extensive monitoring and control solutions. Similarly, its compatibility with GE AI880A 3BSE039293R1 enhances data acquisition and processing, making it a powerful tool for real-time decision-making.

In conjunction with models like GE 336A3435ALGO1 and GE 8LSA55.E3030D000-1, the GE 531X111PSHATG1 further strengthens system reliability and performance, ensuring that operations run smoothly across various industrial applications. Its role alongside the GE DS200RTBAG1A is particularly notable in providing comprehensive feedback and control mechanisms, vital for automated systems.

In conclusion, the GE 531X111PSHATG1 is a premier solution tailored for the power industry, petrochemical applications, and general automation needs. With its advanced features, exceptional performance, and compatibility with a wide range of GE models, it is positioned as a vital component for industries seeking efficiency and reliability in their operations. Embrace the future of automation with the GE 531X111PSHATG1 and experience unparalleled performance in your industrial applications.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

.png)